Light guide optical fiber andlight guide system thereof co-composing by coaxial semiconductor light source and light detector

A technology of coaxial light and semiconductor, applied in the field of coaxial light guide system, can solve the problems of unable to do high power output, irreplaceable, unfavorable power improvement, etc., and achieve the effect of avoiding the loss of incident light power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

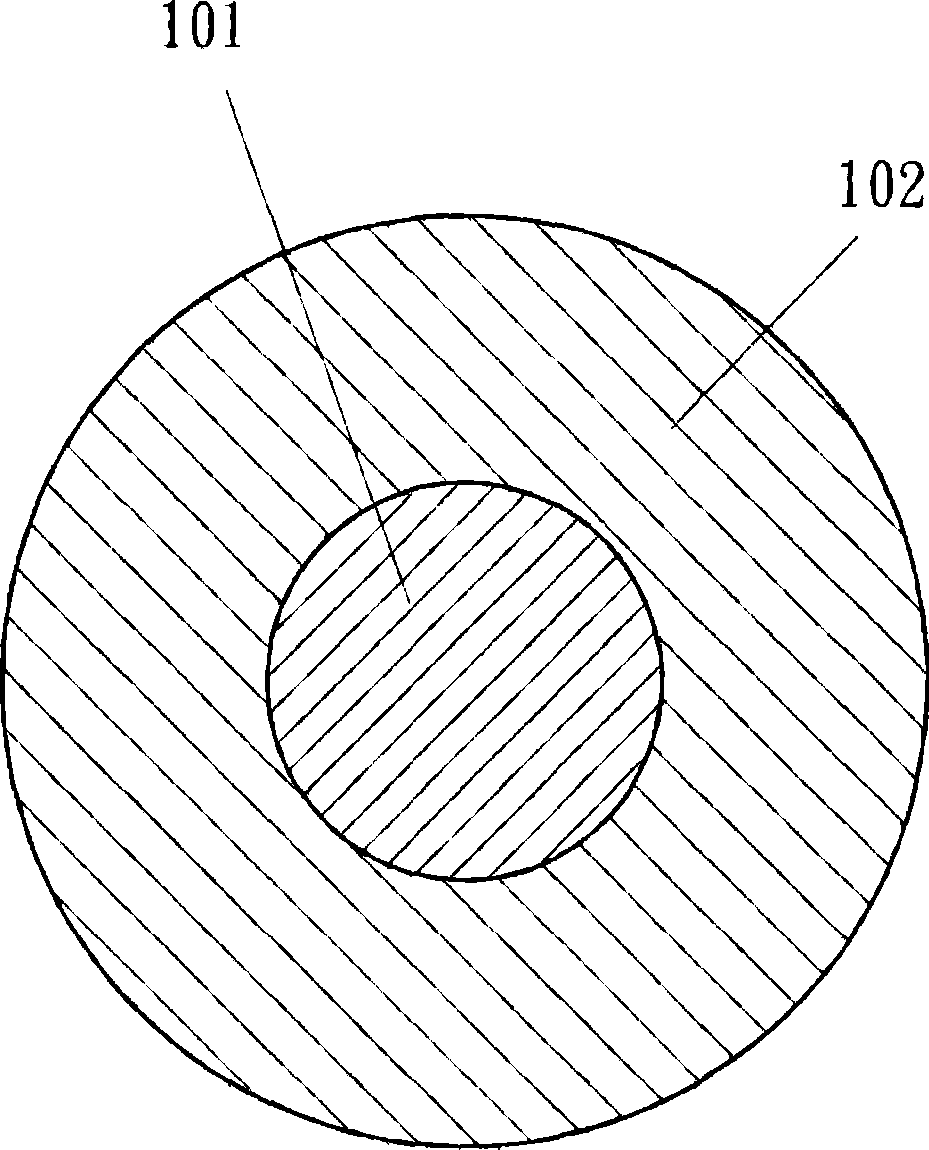

[0114] Taking a coaxial optical fiber, a coaxial light source, and a coaxial photodetector to form an optical fiber with a coaxial coaxial structure and a transceiver end structure as an example, as shown in FIG. 15 for illustration. The components of the various reference numbers quoted in the examples of the present invention can be regarded as the same or functionally similar components, and it is intended to illustrate the main implementation features represented by the examples in a very simplified diagrammatic manner; therefore, this illustration It is not intended to depict all of the features of an actual embodiment, nor is it intended to depict the relative dimensions of the depicted components, so the figures shown are not drawn to scale, but are drawn in accordance with the general spirit of the coaxial light guide of the present invention.

[0115] Referring to Figure 15, the light source A is a coaxial semiconductor laser, which shows a partial cross-sectional view...

Embodiment 2

[0128] Figure 16 It is a simplified cross-sectional view of the structure of Embodiment 2 of the coaxial light guide system, which is an application example in which coaxial semiconductor transceivers are coaxially co-fabricated on the same substrate 1602 to share the only coaxial optical fiber 801 and save one optical fiber. In traditional fiber optic transceivers, the light source emitter and the light detector for optical signal reception are manufactured separately and then assembled together. Because the optical fiber itself has bidirectional optical waveguide capability, for example, the coaxial semiconductor optical transmitter and receiver of the present invention can be coaxially fabricated on the same substrate, which can save a lot of hardware construction costs. Because the three are coaxial, it is very easy to overlap up and down, co-construct and utilize each other, resulting in various application combinations. The upper layer of this transceiver is the APD phot...

Embodiment 3

[0130] Take a color display structure composed of 1024 coaxial color light emitting diodes in a horizontal row and 768 coaxial color light emitting diodes in a vertical row as embodiment 3, as shown in FIG. 17 for illustration. Referring to FIG. 17 , each light-emitting system in the color display is composed of 1024×768=786432 coaxial color light-emitting diodes as shown in FIG. 18 . Coaxial color light-emitting diodes are color light-emitting diodes (hereinafter referred to as coaxial color light-emitting diodes CCLED-COAXIAL COLOR LIGHT EMITTING DIODES) formed by sharing the axis of the coaxial three-color light-emitting diodes. 1801 is the three-color axis common electrode, 1802 is the red R layer, 1803 is the green G layer, 1804 is the blue B layer, 1805 is the red R coaxial outer ring power supply electrode, 1806 is the green G coaxial outer ring power supply electrode, 1807 is the blue B coaxial outer annular power supply electrode, 1808 is the base plate, 1809 is the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com