Substrate processing method

A substrate processing method and substrate technology, which are applied to the original parts, optics, and instruments used for photomechanical processing, can solve the problems of inability to maintain stable etching characteristics of phosphoric acid aqueous solution, long downtime, etc., and achieve long-term stable etching speed. Significantly increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

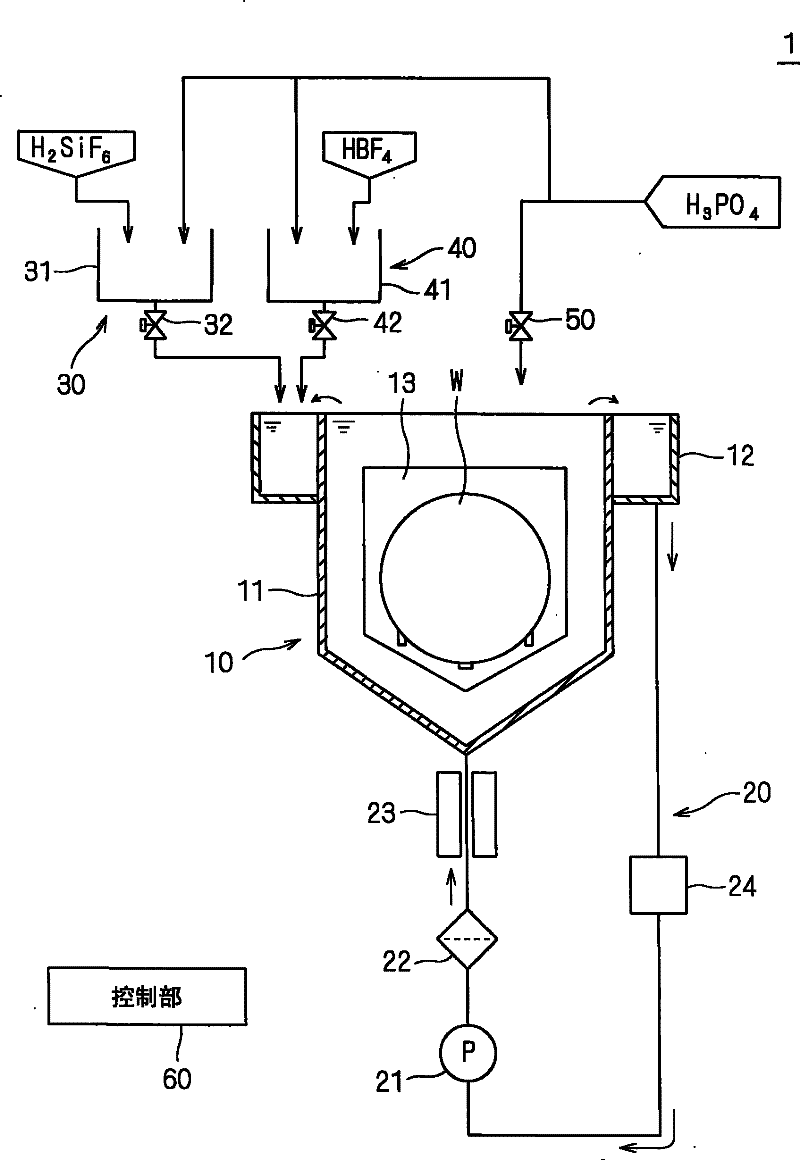

[0039] figure 1It is a figure which shows the overall schematic structure of the substrate processing apparatus of this invention. This substrate processing apparatus 1 is a wet etching processing apparatus for immersing a substrate W formed with a silicon oxide film and a silicon nitride film in an aqueous phosphoric acid solution, and selectively etching the silicon nitride film. Processing device. The substrate processing apparatus 1 has: a immersion treatment tank 10, which stores a phosphoric acid aqueous solution, and performs etching treatment; a circulation path 20, which circulates the phosphoric acid aqueous solution to the immersion treatment tank 10; Additives are put into the aqueous solution; the collecting agent feeding mechanism 40 is used to put the collecting agent into the phosphoric acid aqueous solution in the immersion treatment tank 10 .

[0040] The immersion treatment tank 10 has a two-layer tank structure composed of an inner tank 11 that stores an ...

no. 2 approach

[0074] Next, a second embodiment of the present invention will be described. The structure of the substrate processing apparatus 1 of the second embodiment is completely the same as that of the substrate processing apparatus 1 of the first embodiment. The difference between the second embodiment and the first embodiment lies in the timing of injecting the trapping agent. In the first embodiment, the trapping agent is injected every time the substrate group consisting of a predetermined number of substrates W is etched, but in the second embodiment, based on the concentration of siloxane measured by the concentration meter 24 Concentration, into the collector.

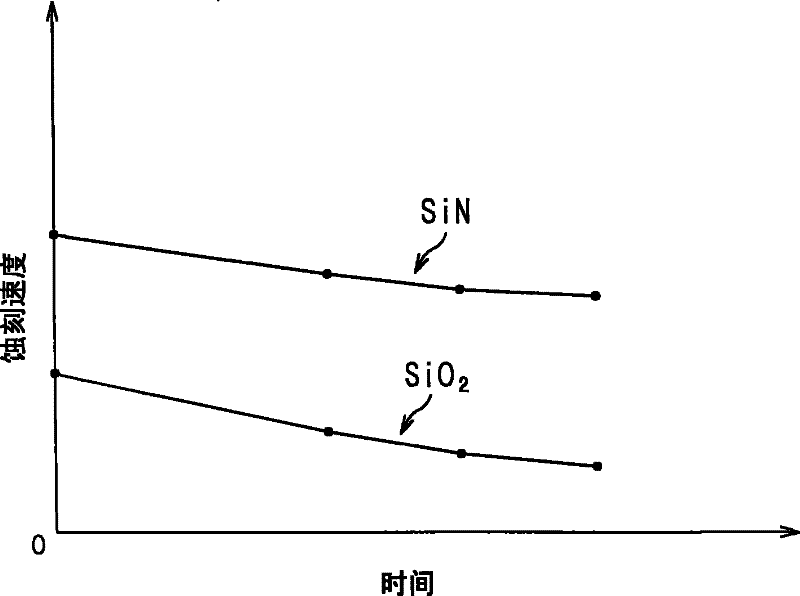

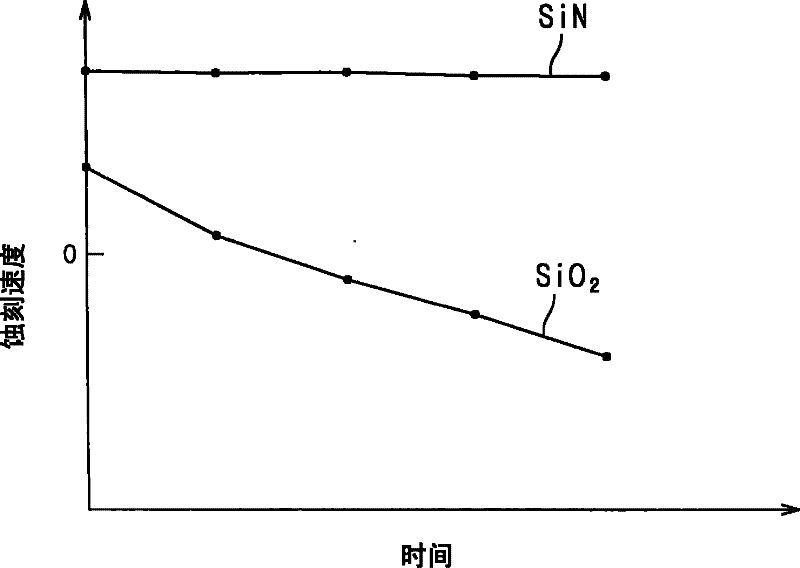

[0075] In the second embodiment, in order to increase the etching selectivity of the silicon nitride film, an additive containing an aqueous solution of hexafluorosilicate is initially injected, and the control unit 60 controls the additive input mechanism 30 to inject it sequentially at predetermined intervals. By ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com