Method for preparing rocuronium crystalline hydrate

A technology of crystalline hydrate and rocuronium bromide, which is applied in the fields of steroids and organic chemistry, and can solve problems such as unfavorable storage, instability, and easy moisture absorption of rocuronium bromide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

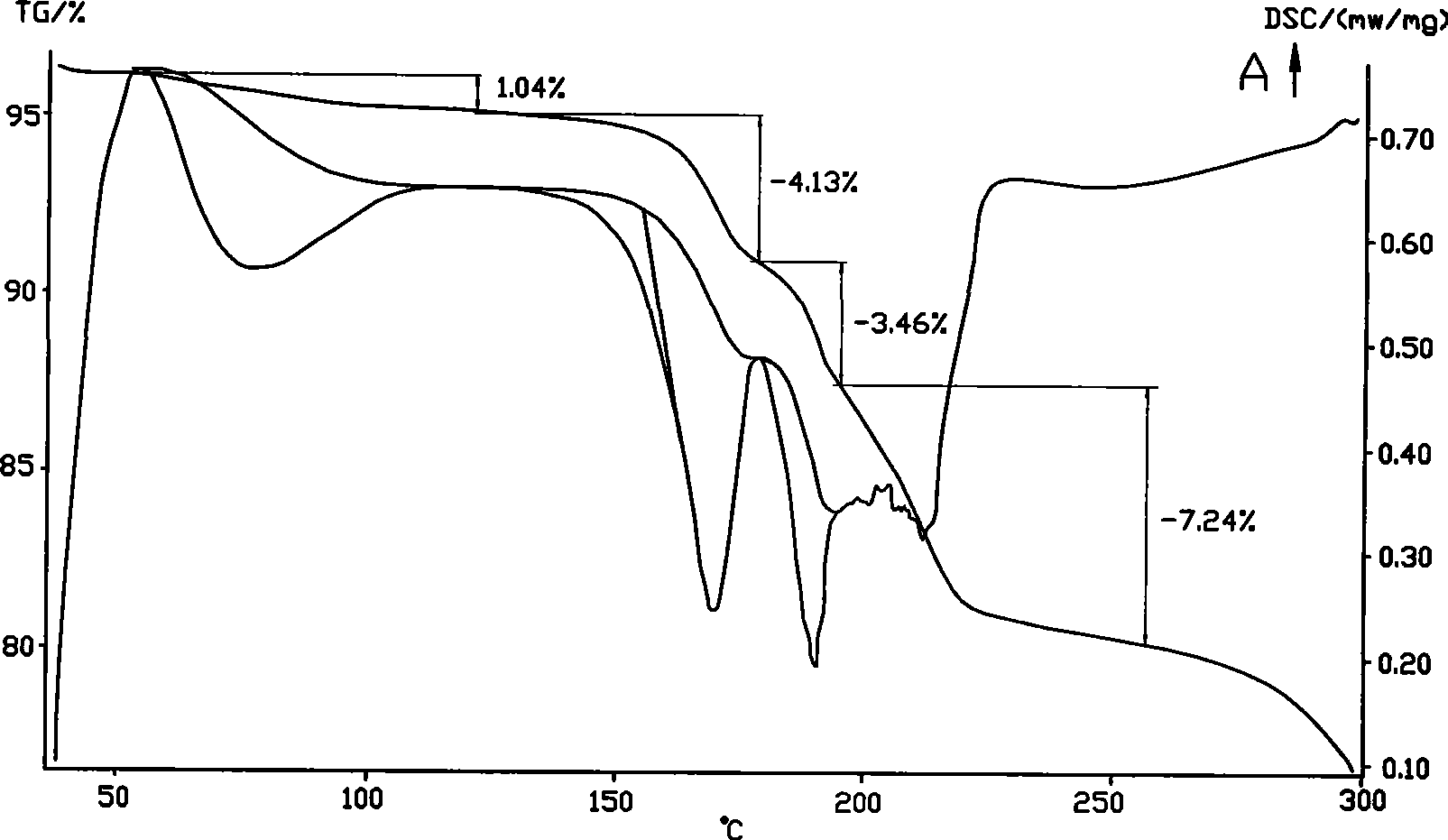

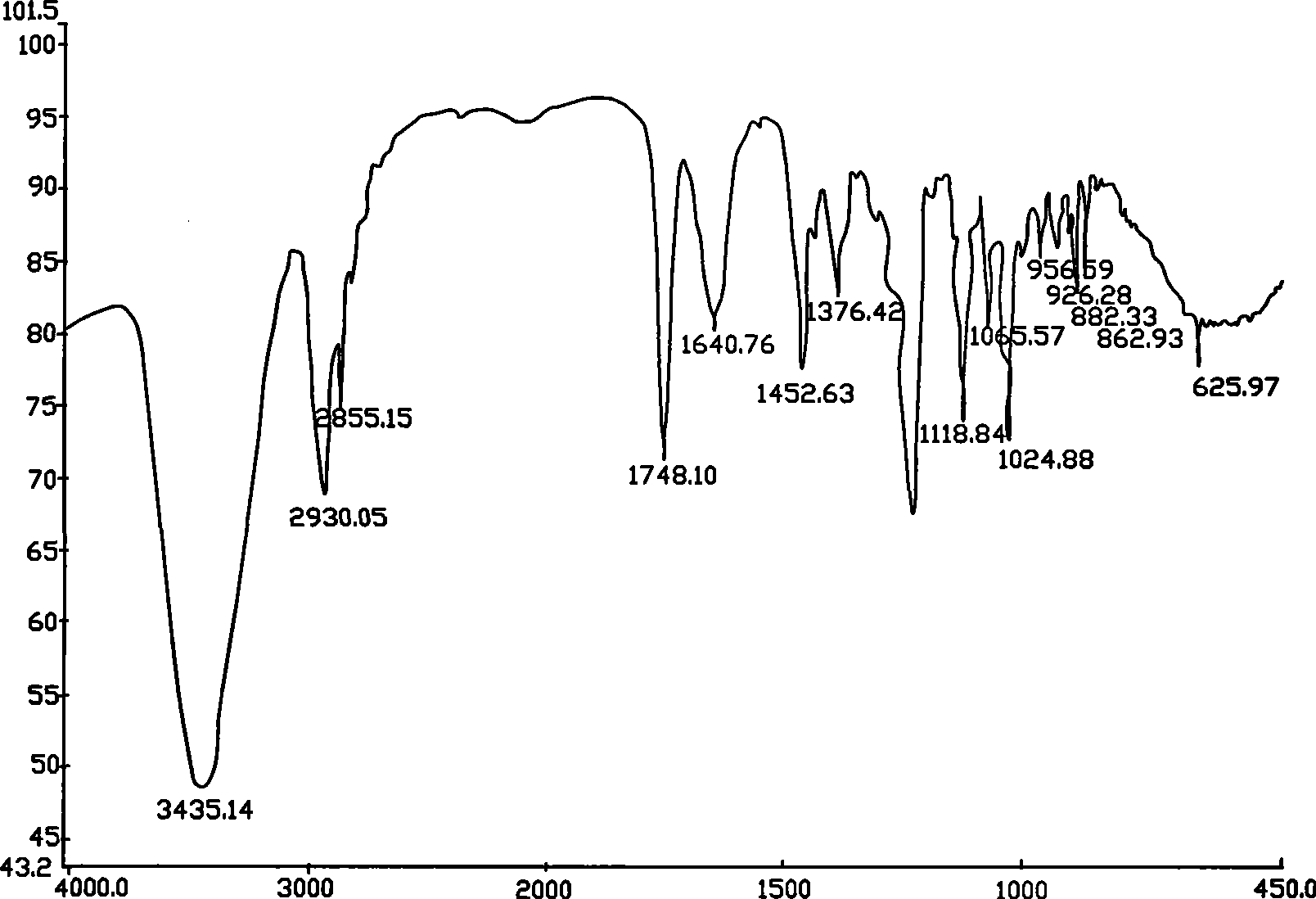

Embodiment approach 1

[0019] Weigh 3.0g of rocuronium bromide into a 50mL single-necked bottle, add 40mL of distilled water, shake to dissolve, pour it into a petri dish, then put the petri dish into the lyophilizer, and lower the temperature in the lyophilizer to— At 40°C, the solution in the culture dish was frozen into ice, vacuumized, and when the pressure was reduced and the temperature was raised to 40°C within 15 hours, it was vacuum-dried for 20 hours to obtain rocuronium bromide crystalline hydrate (containing 1.5 crystal water) 2.8 g.

[0020] Elemental analysis: C32H53BrN2O4.1.5 H2O theoretical value C 60.28%, H 8.79%, Br 12.72%, N 4.40%, O 13.81%; measured value C 60.14%, H 8.89%, Br 12.64%, N 4.37%, O 13.96% . The organic solvent residue of rocuronium bromide was 10.36% before freeze-drying, and the organic solvent residue in rocuronium bromide crystalline hydrate was 0.05% after freeze-drying.

Embodiment approach 2

[0022] Weigh 1.5g of rocuronium bromide into a 50mL single-necked bottle, add 45mL of distilled water, shake to dissolve, pour it into a petri dish, then put the petri dish into the freeze dryer, and lower the temperature inside the freeze dryer to— 50°C, freeze the solution in the petri dish into ice, vacuumize, heat up to 50°C under reduced pressure within 20 hours, heat and vacuum dry for 30 hours, and get rocuronium bromide crystalline hydrate (containing 1.5 crystal water) 1.4 g.

[0023] Elemental analysis: C32H53BrN2O4.1.5H2O theoretical value C 60.28%, H 8.79%, Br 12.72%, N 4.40%, O 13.81%; measured value C 60.23%, H 8.81%, Br 12.69%, N 4.39%, O 13.88% . The organic solvent residue of rocuronium bromide before freeze-drying was 10.36%, and the organic solvent residue in rocuronium bromide crystalline hydrate after freeze-drying was 0.07%.

Embodiment approach 3

[0025] Weigh 1.5g of rocuronium bromide into a 50mL single-necked bottle, add 10mL of distilled water, shake to dissolve, pour it into a petri dish, then put the petri dish into the freeze dryer, and lower the temperature inside the freeze dryer to— 30°C, freeze the solution in the petri dish into ice, vacuumize it, and heat it up to 30°C under reduced pressure within 10 hours, keep it warm and vacuum dry for 10 hours, and get rocuronium bromide crystalline hydrate (containing 1.5 crystal water) 1.3 g.

[0026] Elemental analysis: C32H53BrN2O4.1.5 H2O theoretical value C 60.28%, H 8.79%, Br 12.72%, N 4.40%, O 13.81%; measured value C 60.25%, H 8.80%, Br 12.68%, N 4.37%, O 13.90% . The organic solvent residue of rocuronium bromide before freeze-drying was 10.36%, and the organic solvent residue in rocuronium bromide crystal hydrate after freeze-drying was 0.04%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com