Processing method of odor type fabric with long lasting fragrance depositing

A processing method and durable technology, applied in the processing of textile materials, fiber processing, textiles and papermaking, etc., can solve problems such as the inability to meet the physical properties requirements of umbrella fabrics, and improve production efficiency, increase sales revenue, and improve production efficiency. The effect of increased speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

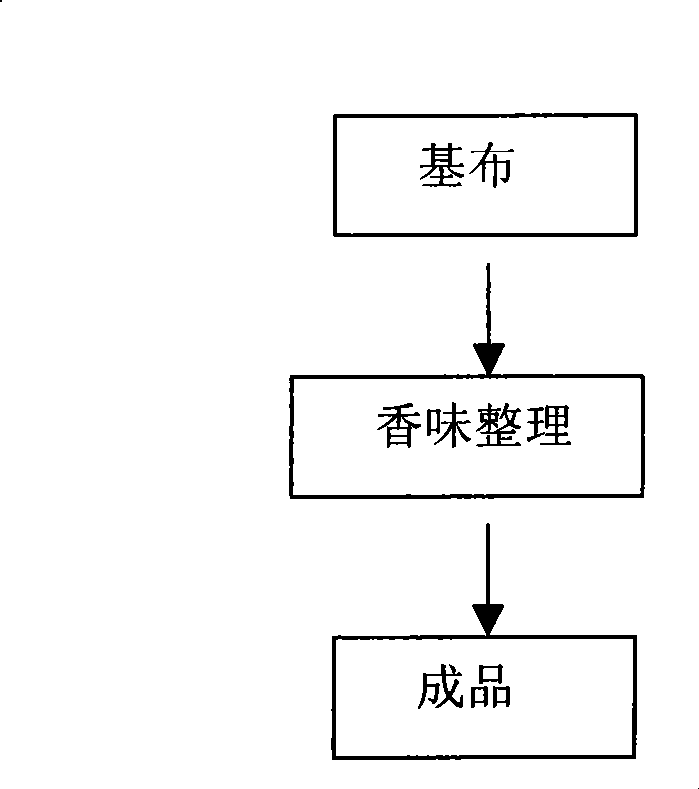

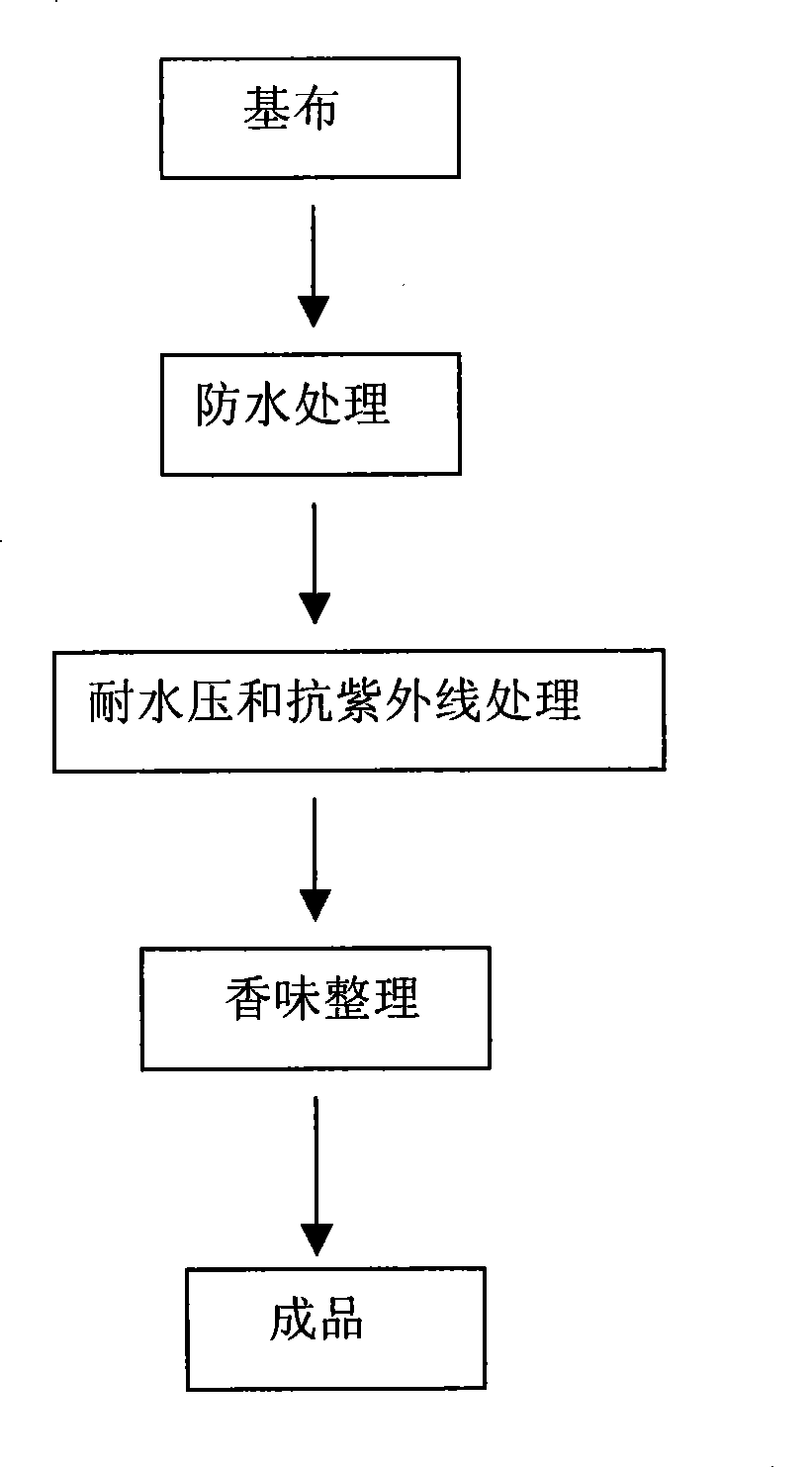

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Polyester-cotton interwoven jacquard scented umbrella fabric

[0021] (1) The water repellent aqueous solution is prepared by 3 parts of water repellant TG420 and 97 parts of water by weight, the base cloth is immersed in the water repellent aqueous solution, and then the excess solution is squeezed out through the pressure roller, and then enters the oven for drying, so that the fabric has Waterproof function; the drying temperature is controlled at 160°C-180°C, the operating speed of the pressing roller is 60m / min, and the pressure-absorption rate is 75%.

[0022] (2) PA glue SR430, 15 parts by weight of PA glue SR430, 15 parts by weight, and 2 parts of bridging agent AC503 are formulated into a slurry as formula one; then use 100 parts by weight of polyurethane ( PU glue) SS130, 30 parts of toluene, 2 parts of bridging agent SC75, and 3 parts of UV protection agent UV326 are formulated into a slurry to make formula 2; Then enter the oven for drying, so th...

Embodiment 2

[0024] Embodiment 2: Variant satin silk scented umbrella fabric

[0025] (1) The water repellent aqueous solution is prepared by 5 parts of water repellent TG420 and 100 parts of water by weight, the base cloth is immersed in the water repellent water solution, and then the excess solution is squeezed out through the pressure roller, and then enters the oven for drying, so that the fabric has a Waterproof function; the drying temperature is controlled at 160°C-180°C, the operating speed of the pressing roller is 75m / min, and the pressure-absorption rate is 50%.

[0026] (2) PA glue XF3388, 35 parts by weight of PA glue XF3388, 35 parts of toluene (TOL), 3 parts of bridging agent AC503 are formulated into slurry as formula one; then use 80 parts by weight of polyurethane ( PU glue) SS1010, 15 parts of polyurethane (PU glue) SR820, 80 parts of toluene, 3 parts of bridging agent SC75, 2 parts of anti-ultraviolet agent UV327 are deployed into slurry to make formula two; formula on...

Embodiment 3

[0028] Example Three: Jacquard Weaving Colored Silk Scented Umbrella Fabric

[0029] (1) The water repellent aqueous solution is prepared by 1 part of water repellent TG420 and 95 parts of water by weight, the base cloth is immersed in the water repellent aqueous solution, and then the excess solution is squeezed out through the pressure roller, and then enters the oven for drying, so that the fabric has Waterproof function; the drying temperature is controlled at 160°C-180°C, the operating speed of the pressing roller is 65m / min, and the pressure-absorption rate is 65%.

[0030] (2) PA glue SR430, 25 parts by weight of PA glue SR430, 25 parts by weight, and bridging agent AC503 of 1 part are formulated into slurry as formula one; then use 50 parts by weight of polyurethane ( PU glue) SS130, 30 parts of toluene, 1 part of bridging agent SC75, and 2 parts of UV protection agent UV326 are formulated into a slurry to make formula 2; Then enter the oven for drying, so that the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com