Control method and device for stable starting and stopping of turning gear

A technology of a slewing mechanism and a control method, which is applied to fluid pressure actuating devices, mechanical equipment, building structures, etc., and can solve problems such as unstable rotational movement, unstable terminal operation, and inability to accurately stop at a predetermined position, and achieve The effect of flattening the natural frequency peak, realizing smooth control, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

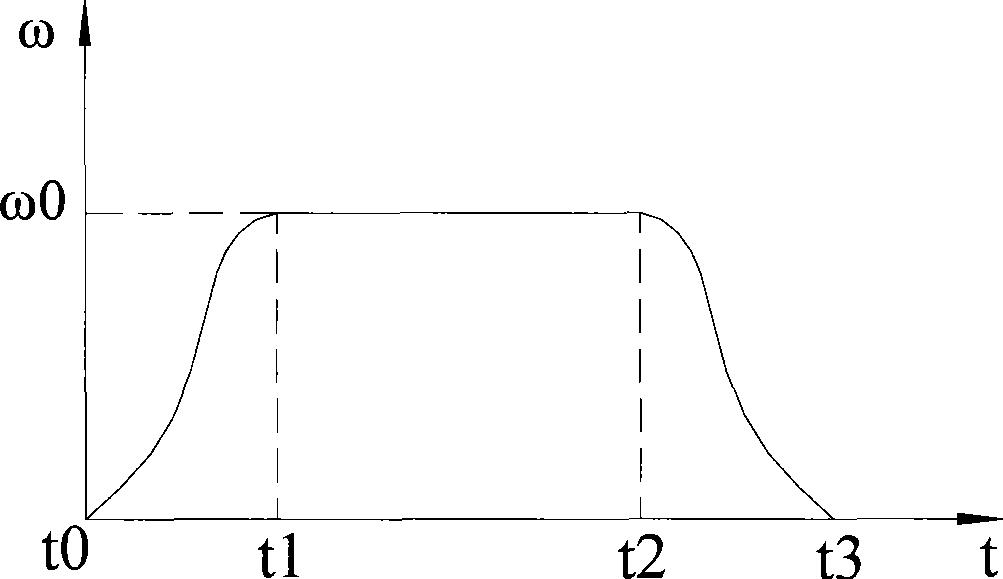

[0036] The gist of the design of the present invention is to obtain an additional impact frequency by controlling the change of the control signal input to the rotary power output mechanism, and weaken the natural frequency generated by the inertial impact, so as to quickly and smoothly realize the start or brake of the rotary mechanism. move.

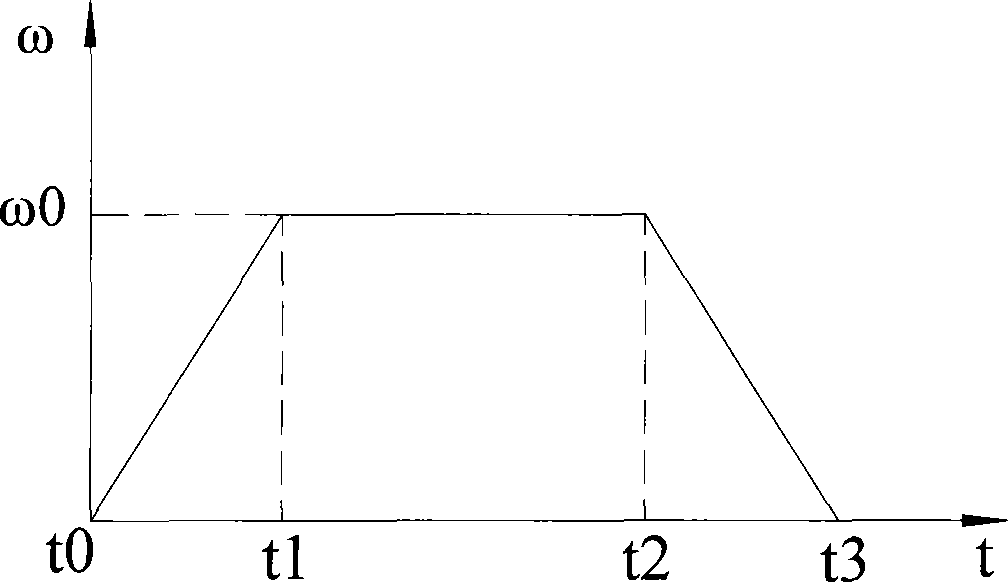

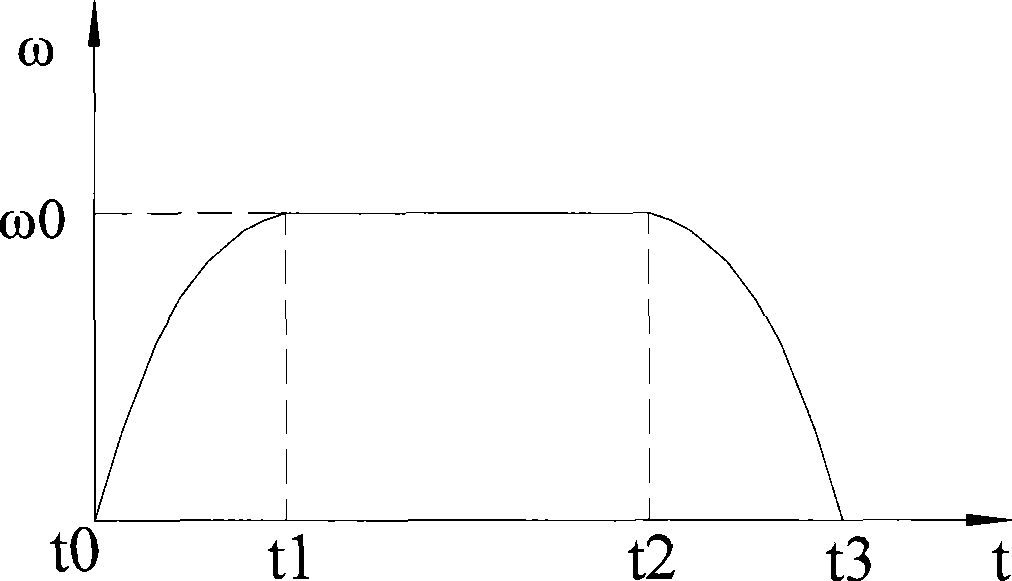

[0037] In fact, the rotary power output mechanism can adopt a hydraulic motor or an electric motor, and the control principle is the same, that is, to control the change law of the pressure oil flow input to the hydraulic motor, or to control the change law of the electric signal input to the electric motor. The following is a detailed description of a rotary mechanism that uses a hydraulic motor to output rotary power. See image 3 , is the flow curve of the control signal input to the rotary power output mechanism as a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com