Method for electrolytic production and refining of metals

A technology of refining metals and electrolysis, which is applied in electric furnaces, crucible furnaces, rotary drum furnaces, etc., and can solve problems such as destroying the properties of electrolytes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

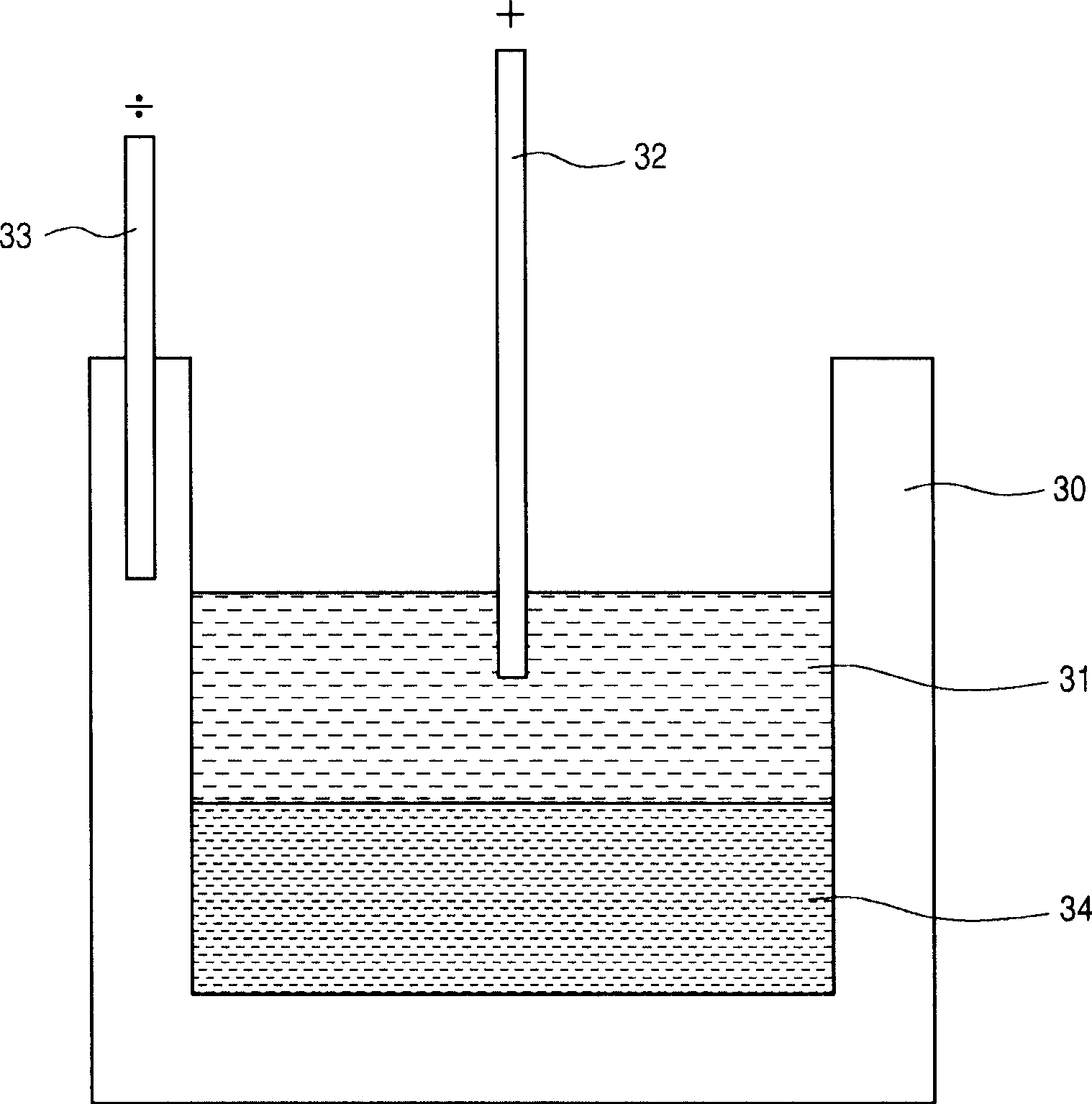

[0077] figure 1 Shown is a schematic diagram of an electrolytic cell, which is used to implement the method for refining silicon of the present invention. The electrolytic cell includes a container 1 having a refractory layer 2. The electrolytic cell has a bottom layer 3 of an alloy of silicon and a metal more expensive than silicon, such as a Cu-Si alloy, which serves as an anode in the electrolytic cell. On the bottom alloy layer 3 there is an oxide-based electrolyte 4 which has a density lower than that of the anode alloy 3 and higher than that of molten silicon. Suitable electrolyte 4 is 50wt% CaO and 50wt% SiO 2 mixture. On top of the electrolyte layer 4 there is a layer 5 of pure silicon metal as a cathode. The anode 4 and the cathode 5 are connected to a DC power source (not shown) through contacts 6 and 7, respectively, to introduce current into the electrolytic cell. When a direct current passes through the electrolytic cell, the silicon in the anode alloy 3 enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com