Arrester

A technology for lightning arresters and electrical equipment, applied in the field of lightning arresters, to achieve the effects of simplifying equipment structure, suppressing partial discharge, and preventing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

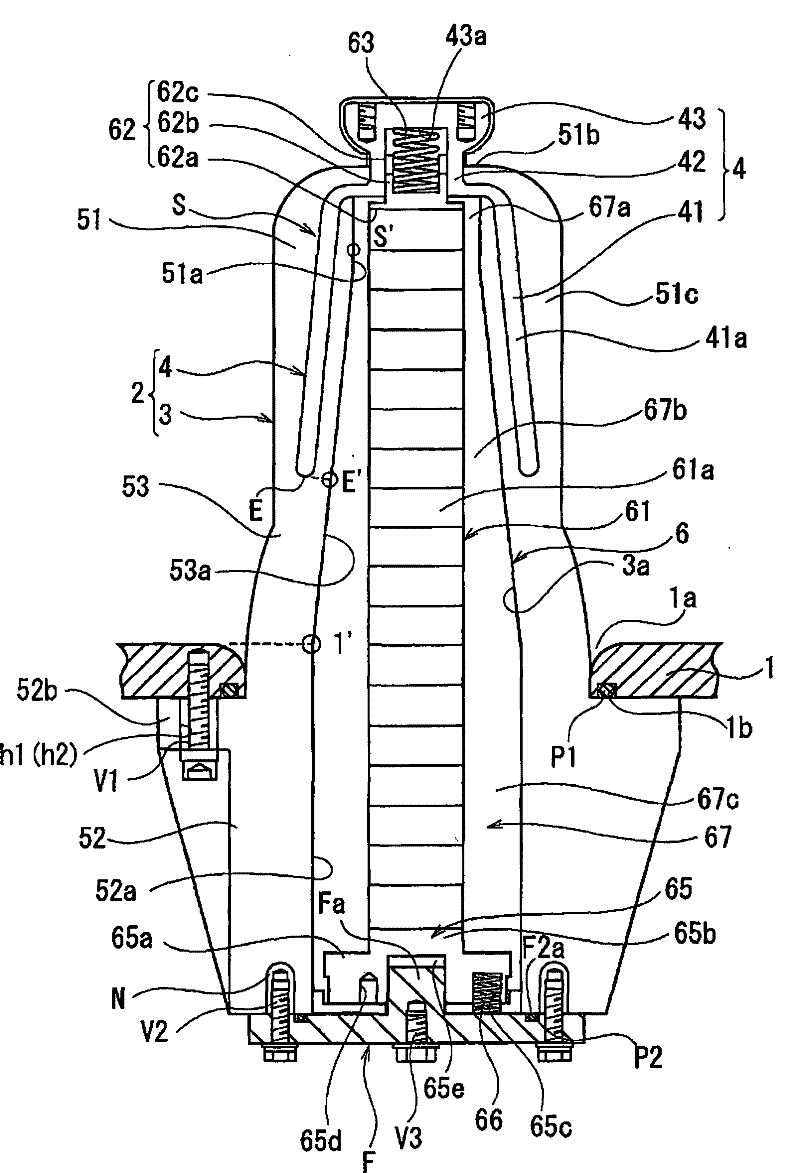

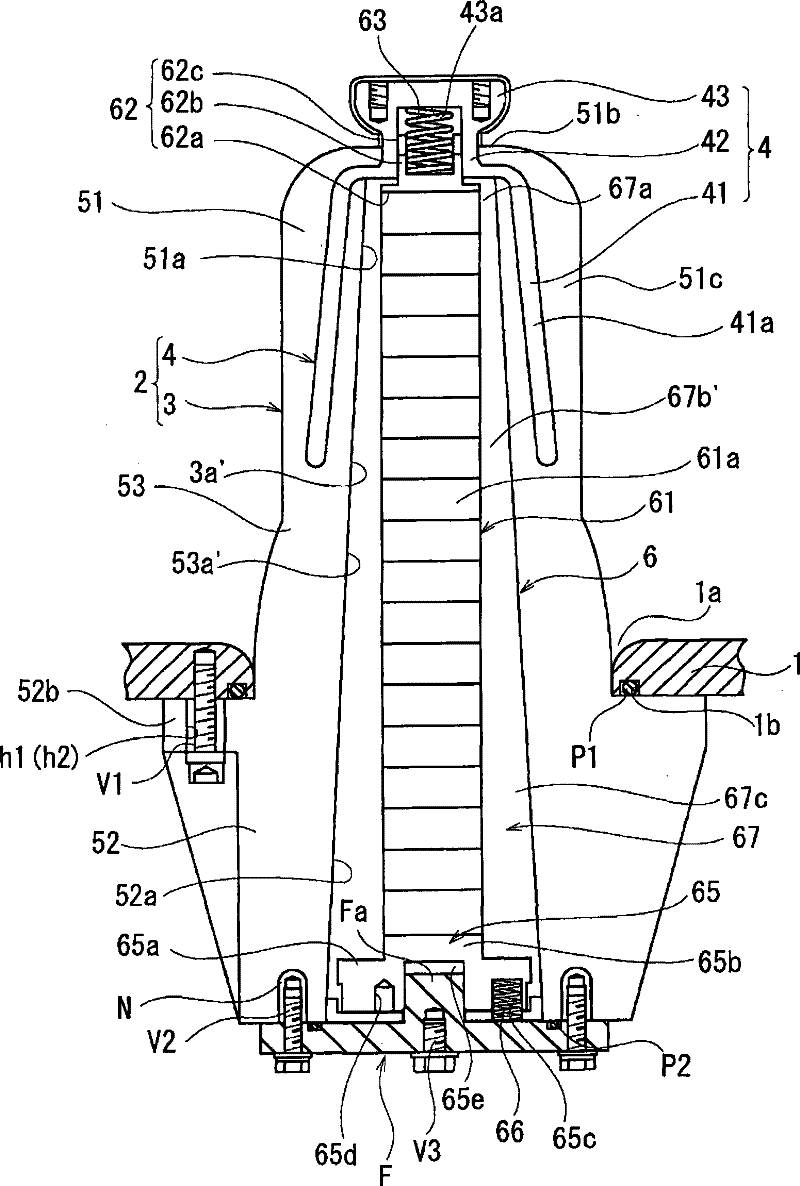

[0039] figure 1 It is a partial cross-sectional view showing an example of a 66 / 77 kV class lightning arrester of the present invention.

[0040] In this figure, the electrical equipment having the lightning arrester of the present invention is provided with an equipment box 1 that airtightly accommodates electrical equipment such as switches (not shown), and in the equipment box 1, for example, SF 6 gas and other insulating gases. Moreover, an opening 1a is provided at the bottom of the equipment box 1, and a sleeve 2 is arranged in the opening 1a. The front end of the sleeve 2 itself is located in the equipment box 1, and the middle portion of the sleeve 2 closes the opening. The portion 1 a is airtightly covered, and a lightning arrester mold body 6 described later is detachably mounted in the sleeve 2 .

[0041] The sleeve 2 is provided with a hard and insulating sleeve body 3 made of epoxy resin mold body, etc., and a high-voltage shield embedded in the front end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com