Fine purification method for rubber vulcanization accelerant 2-mercaptobenzothiazole (M)

A technology of mercaptobenzothiazole and rubber vulcanization, which is applied in the direction of organic chemistry, can solve the problems of refractory black tar, speed up rubber and vulcanizing agent, and low product quality, and achieve high purity, reduced dosage, and high melting point. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

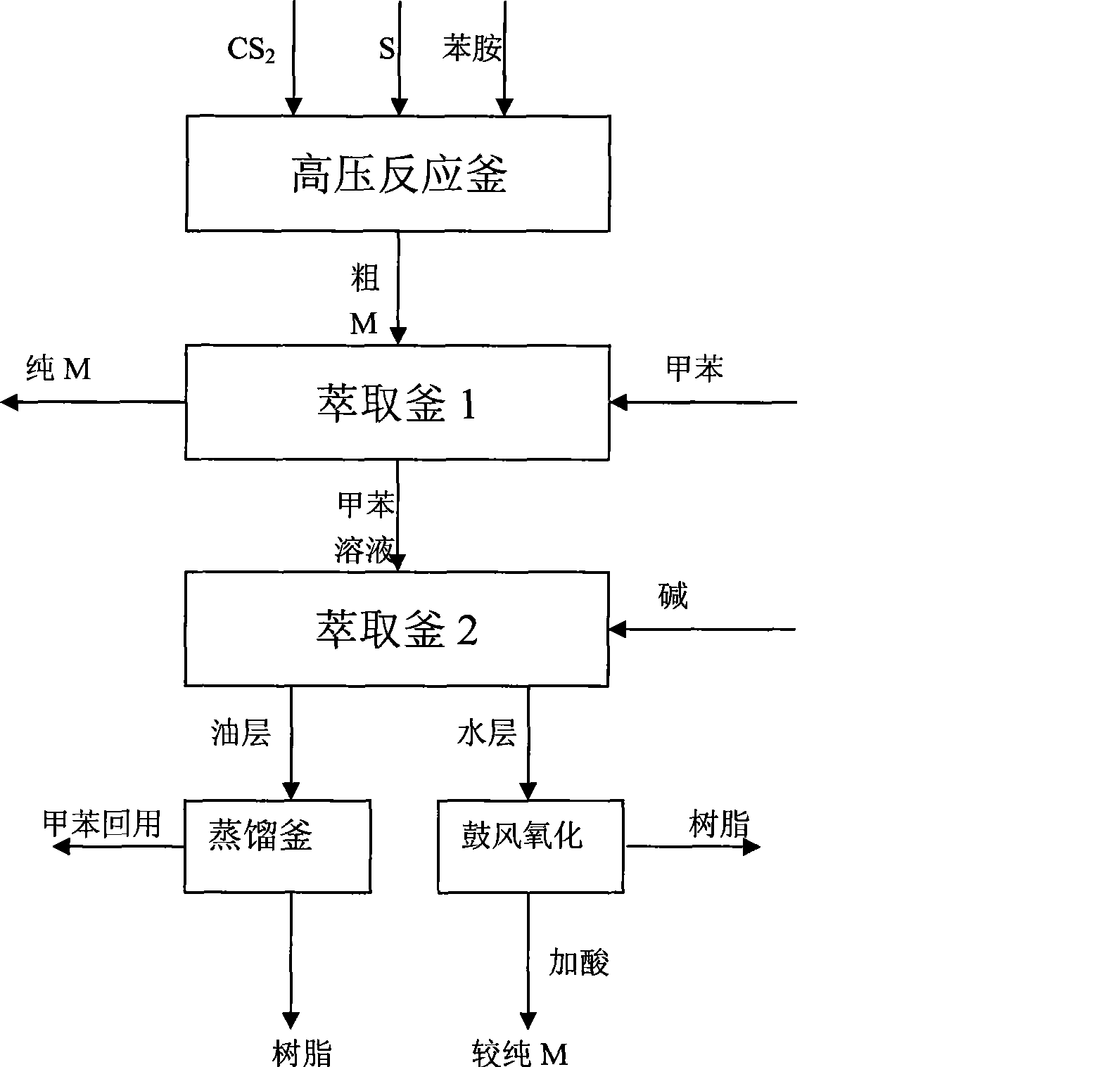

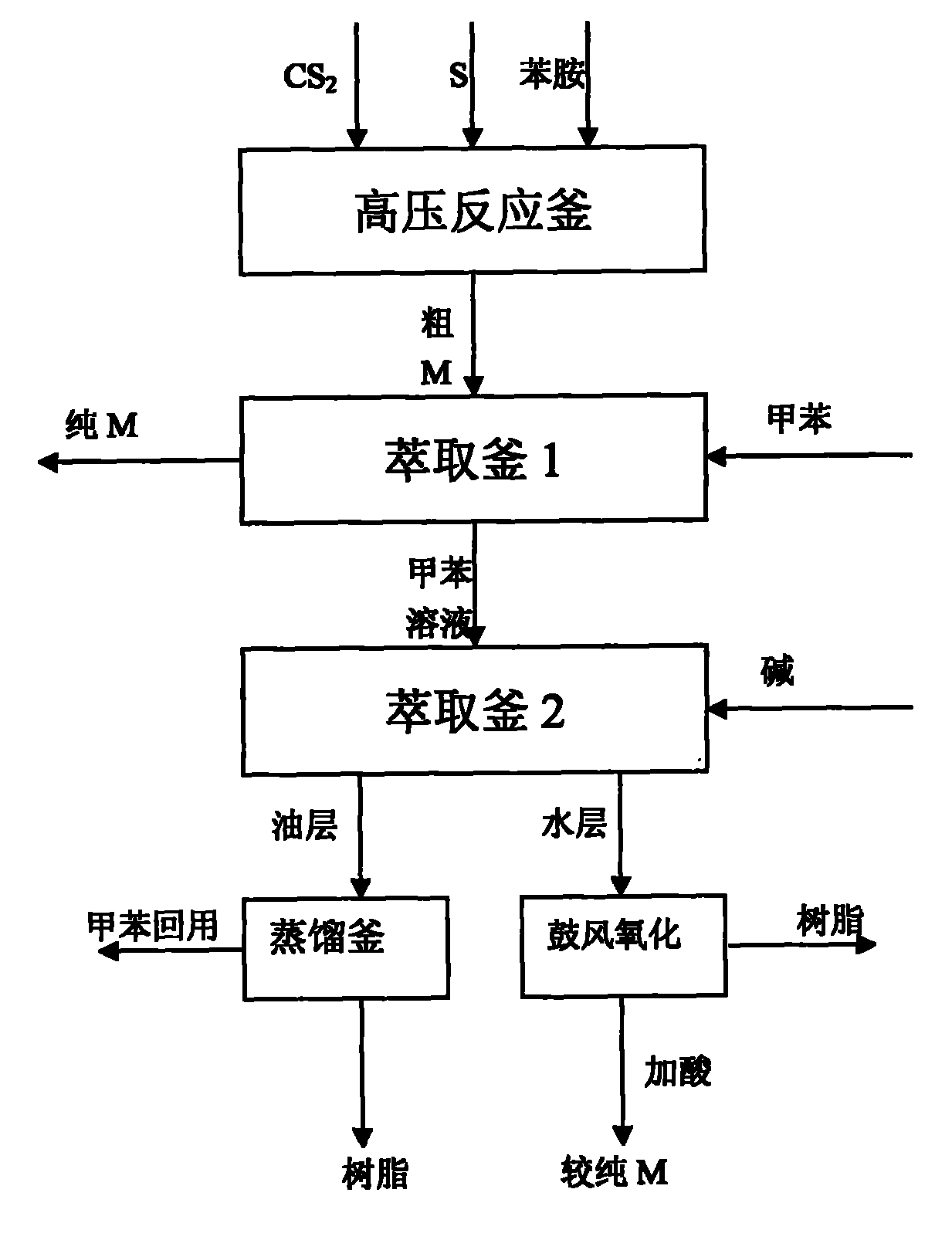

[0011] This invention is described in detail in conjunction with accompanying drawing:

[0012] 1. React with aniline, carbon disulfide and sulfur at 250°C and 9.0-10.0 MPa for two hours to produce crude rubber vulcanization accelerator M with a mass content of about 85.0%. The remaining impurities include: resin about 12.5%, intermediate product about 2.5%. Add 100g of crude rubber vulcanization accelerator M into an extraction kettle containing 200ml of toluene, keep the temperature at 35±2°C, and stir at a rate of 170r / min. After 2 hours, open the extraction kettle to release the toluene solution. Then add 130ml of toluene to the extraction kettle, keep the temperature at 35±2°C, and stir at a rate of 170r / min. After 1 hour, release the toluene solution. Finally, 100ml of toluene was added to the extraction kettle, suction filtered, and 79.24g of rubber vulcanization accelerator M was obtained after drying, with a purity of 98.5% and a melting range of 171-176°C.

[0013]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com