Foamable hot melt adhesive composition and uses thereof

A composition and foaming heat technology, applied in the bonding method, adhesive, lamination and other directions using foaming adhesive, can solve the problem of aluminum composite panel PE consumption, high cost, heat preservation, sound insulation and heat insulation Poor performance and other problems, to achieve good flame retardant performance, low density, good sound insulation and heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

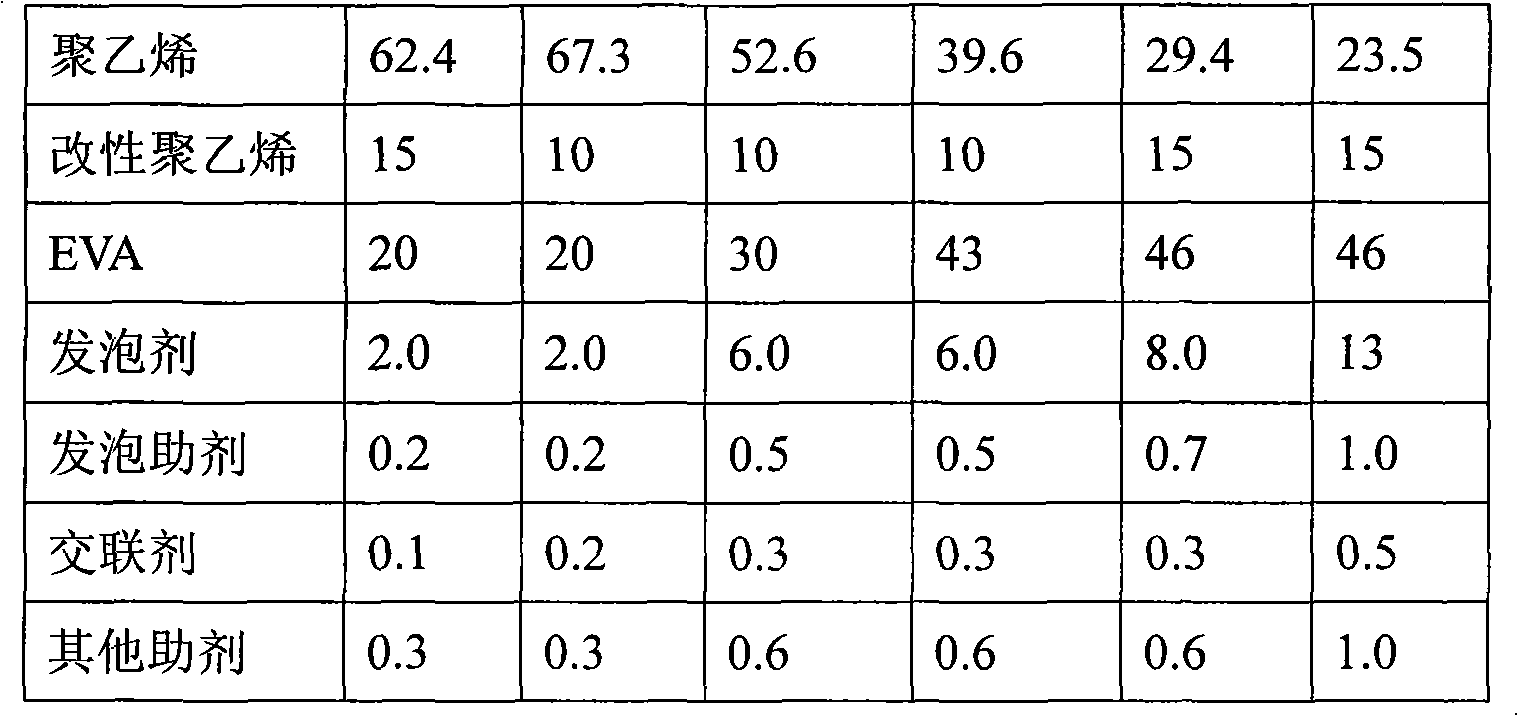

[0019] The invention is a foamable hot-melt adhesive composition used for the core material of a halogen-free flame-retardant aluminum-plastic plate. The formula includes the following components in parts by weight: 10-65 parts of polyethylene, modified ethylene polymer 5-20 parts, EVA 5-60 parts, foaming agent 0.1-15 parts, foaming auxiliary agent 0.02-2 parts, cross-linking agent 0.1-0.8 parts, other auxiliary agents 0.5-5.0 parts.

[0020] Among them, polyethylene is compounded by one or more of high-pressure polyethylene, high-density polyethylene or linear low-density polyethylene, and its melt flow rate is 0.1-15g / 10min, preferably 0.15-7g / 10min .

[0021] The modified monomer of the modified ethylene polymer is selected from maleic acid (anhydride) and its esters, acrylic acid and its esters, styrene and its derivatives, methacrylates and glycidyl methacrylate Any one or a combination of two or more. Maleic acid (anhydride) and its esters are preferred.

[0022] Modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com