Microporous membrane gas and liquid separator

A technology of gas-liquid separator and microporous membrane, applied in the direction of semi-permeable membrane separation, separation method, membrane technology, etc., can solve the problems of low gas permeability, small effective separation contact area of hollow fiber membrane, etc., and achieve dead volume Small size, prevention of target compound peak broadening, long gas-liquid separation channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

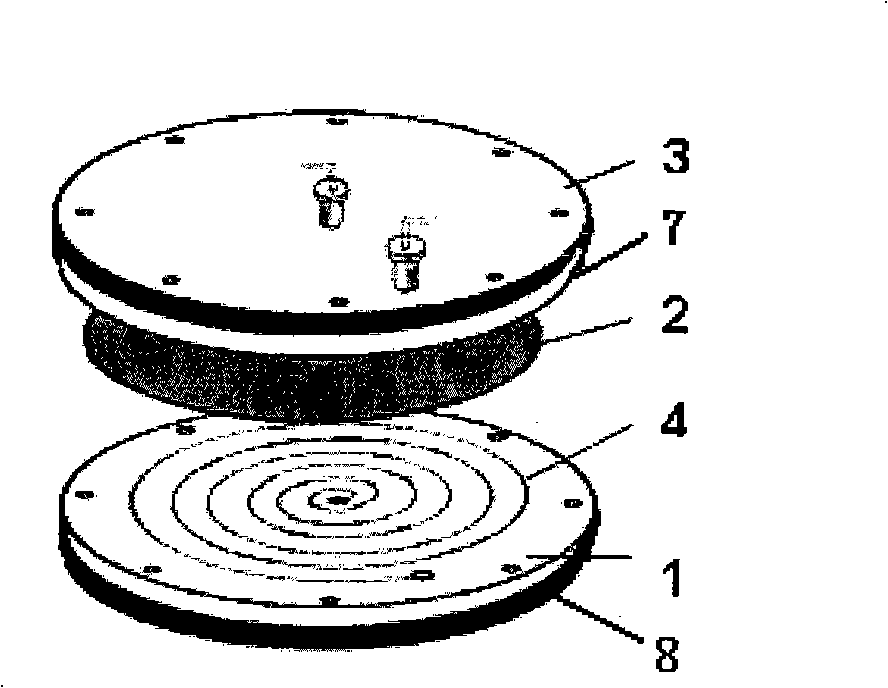

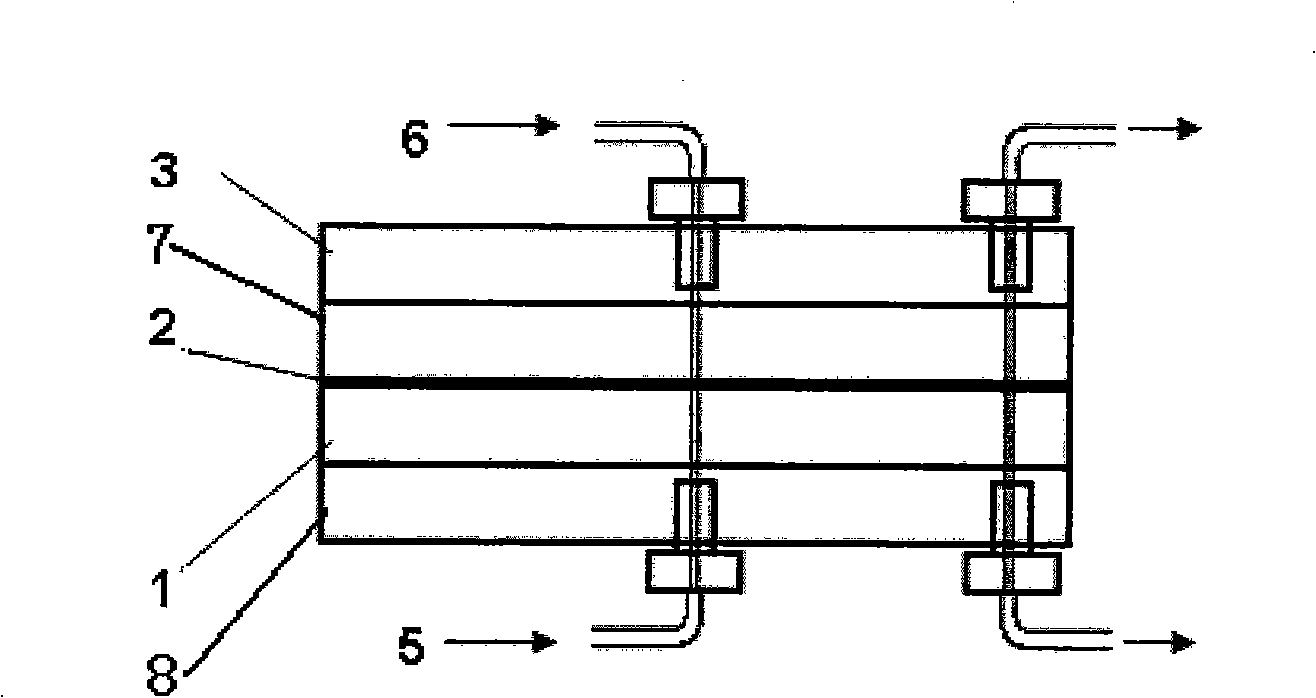

[0018] The microporous membrane gas-liquid separator of this embodiment comprises an upper plate body 7, a lower plate body 1 and a planar hydrophobic microporous air-permeable membrane 2 sandwiched between the upper and lower plate bodies, the upper and lower plate bodies The contact surface with the planar hydrophobic microporous air-permeable membrane 2 is a plane engraved with corresponding helical grooves 4, thereby forming two passages separated by the planar hydrophobic microporous air-permeable membrane 2; The starting ends of the helical grooves 4 of the upper and lower plates are respectively provided with carrier gas inlets and gas-liquid mixture inlets, and the end ends of the helical grooves of the upper and lower plates are respectively provided with carrier gas outlets and gas-liquid mixture outlets.

[0019] The upper and lower discs are made of polytetrafluoroethylene discs, and the contact surfaces of the two polytetrafluoroethylene discs are engraved with cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com