Weight dropper machine control lever type petroleum oil pumping machine

The utility model relates to a pumping unit and lever-type technology, which is applied in the field of heavy-hammer machine-controlled lever-type oil pumping units, which can solve the problems of high energy consumption and high motor power, and achieve the effects of low cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

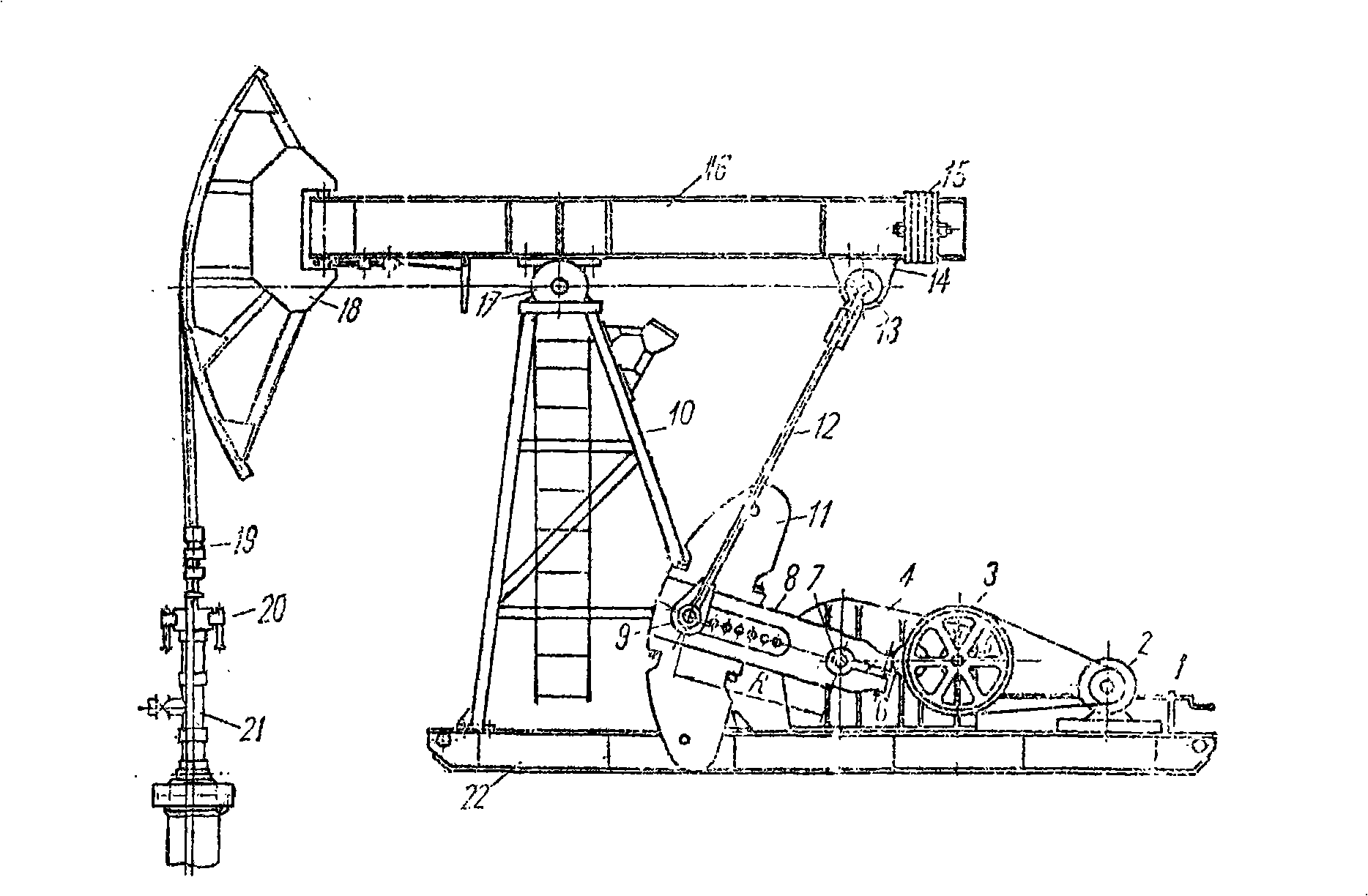

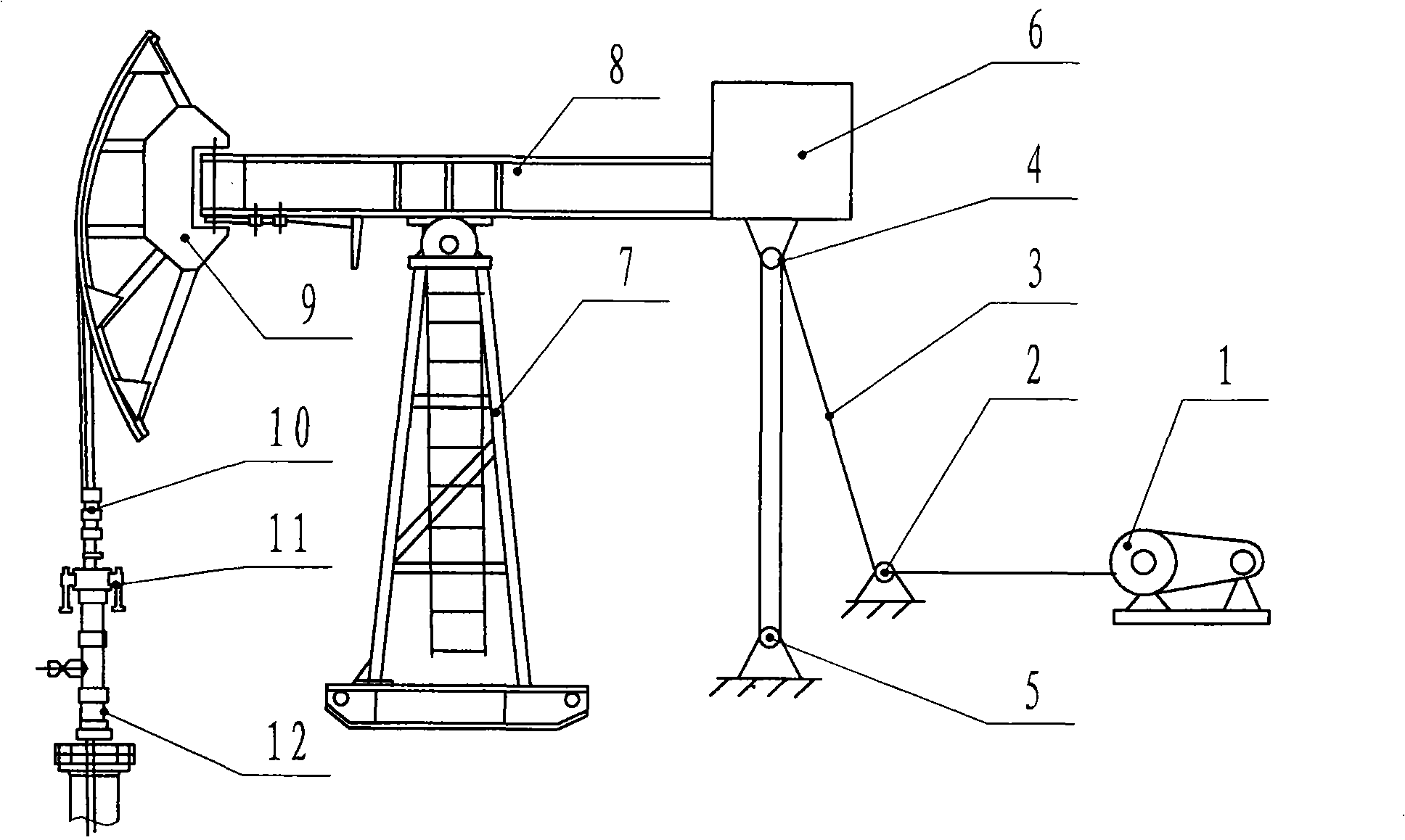

[0020] Such as figure 2 The heavy hammer machine-controlled lever oil pumping unit is mainly composed of hoist 1, reversing pulley 2, steel wire rope 3, movable pulley 4, fixed pulley 5, heavy hammer 6, bracket 7, beam 8, donkey head 9, suspension rope 10, wellhead packing box 11, oil outlet tee 12, the weight 6 is set at the right end of the beam 8, the moving pulley 4 is set under the weight 6 and connected with the weight 6, the steel wire rope 3 goes around the moving pulley 4 and the fixed pulley 5 and the reversing pulley 2 are connected with the winch 1.

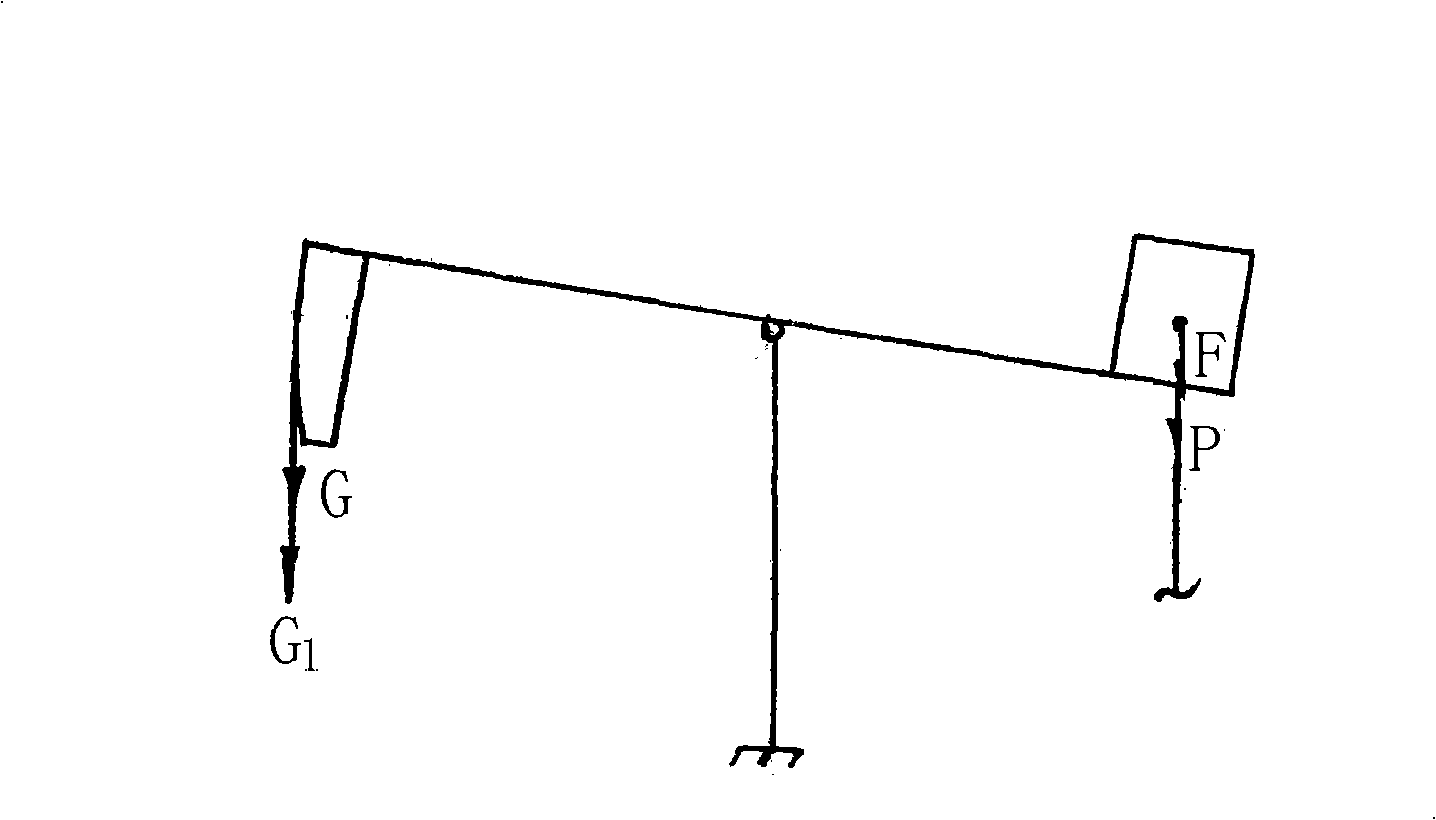

[0021] image 3 A schematic diagram of the force analysis of the hammer mechanically controlled lever oil pumping unit is given when the plunger pump goes up, which shows that the weight F of the heavy hammer 6 plus the traction force P of the winch 1 is greater than the weight G of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com