Full function variable gas distribution controlling mechanism of internal combustion engine

A technology for internal combustion engines and control mechanisms, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as increasing fuel consumption, failing to achieve the purpose of stopping cylinders, increasing engine burden, etc., to achieve fuel saving, simple structure, and low cost. input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

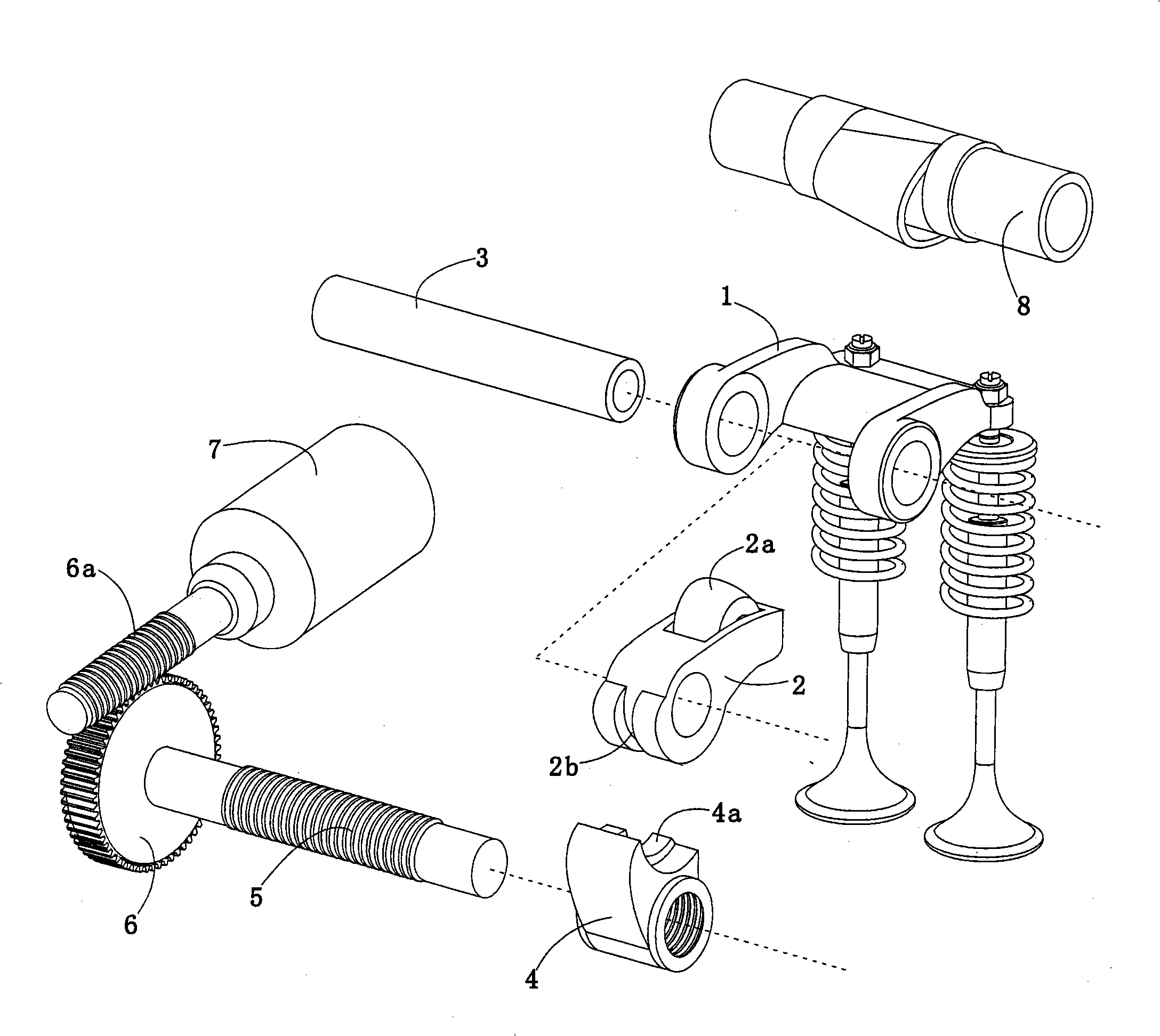

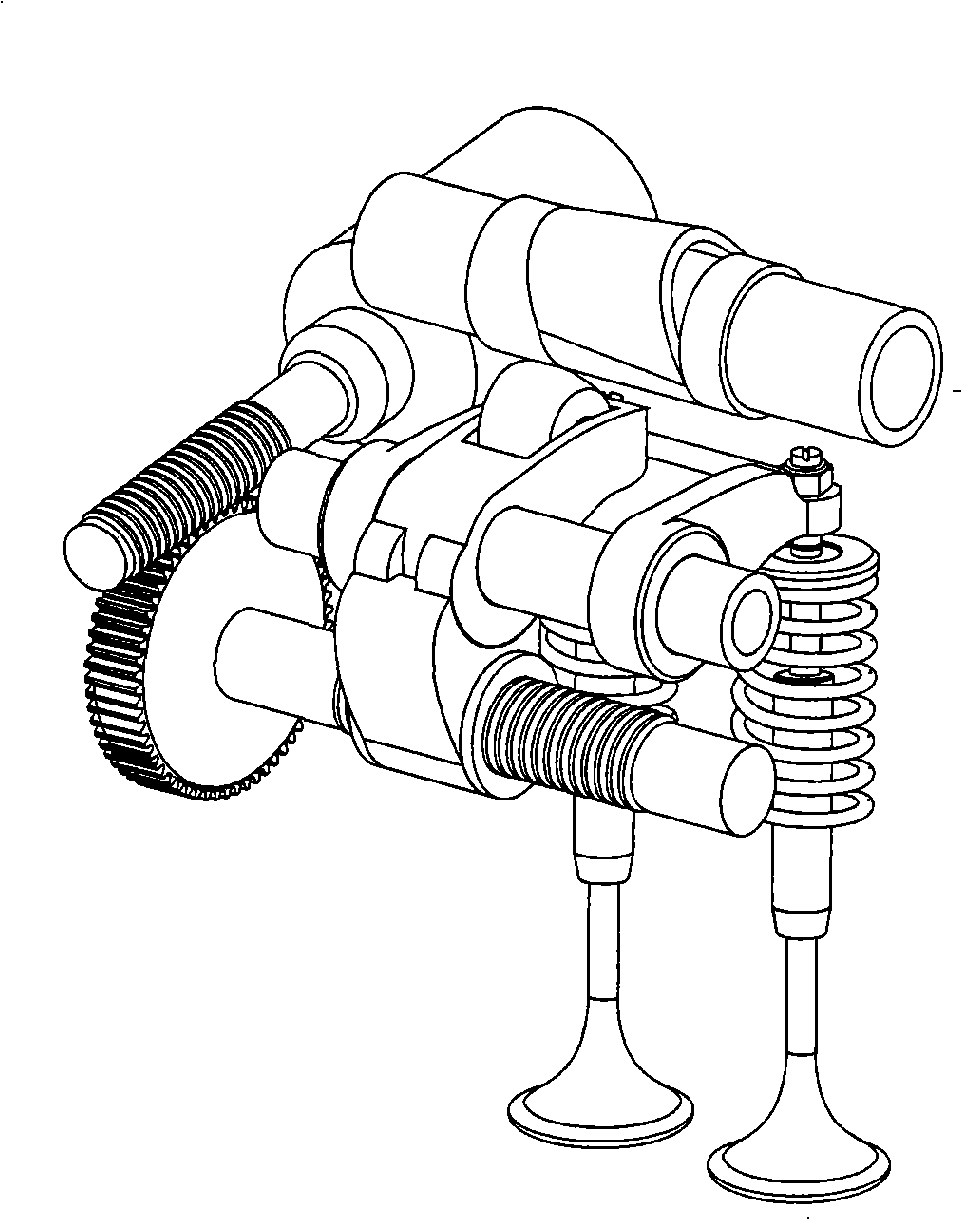

[0052] Cams with unequal shaped beveled cam heads (Fig. 3, Fig. 5) make the cam profile expandable:

[0053] 1. According to the needs, the stepper motors grouped by the microcomputer ECU control synchronously drive the worm and the worm gear to drive the push arm on the screw ( figure 1 ) or a push ring (fig. 6) to make a variable rocker arm with roller wheels ( figure 1 , Figure 6) Translate on the driven rocker arm, and due to the change in the radial length of the cam slope and the change in the rotation angle between the cam and the roller wheel, the valve timing and valve lift that need to be matched under different engine speed conditions can be adjusted. ;

[0054] 2. Apply this method to the DOHC double camshaft overhead type ( figure 1 , Figure 6) and SOHC single overhead camshaft ( Figure 9 ) These two standard engines are equipped with air distribution.

[0055] 3. For the DOHC double camshaft overhead type, the motor controls the intake variable rocker arm an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com