Large-scale high and middle pressure full plastic centrifugal fan

A centrifugal and ventilator technology, applied in mechanical equipment, non-variable pumps, machines/engines, etc., can solve the problems of high price and complex structure, achieve good corrosion resistance, ensure welding quality, ensure disassembly and neutral effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings.

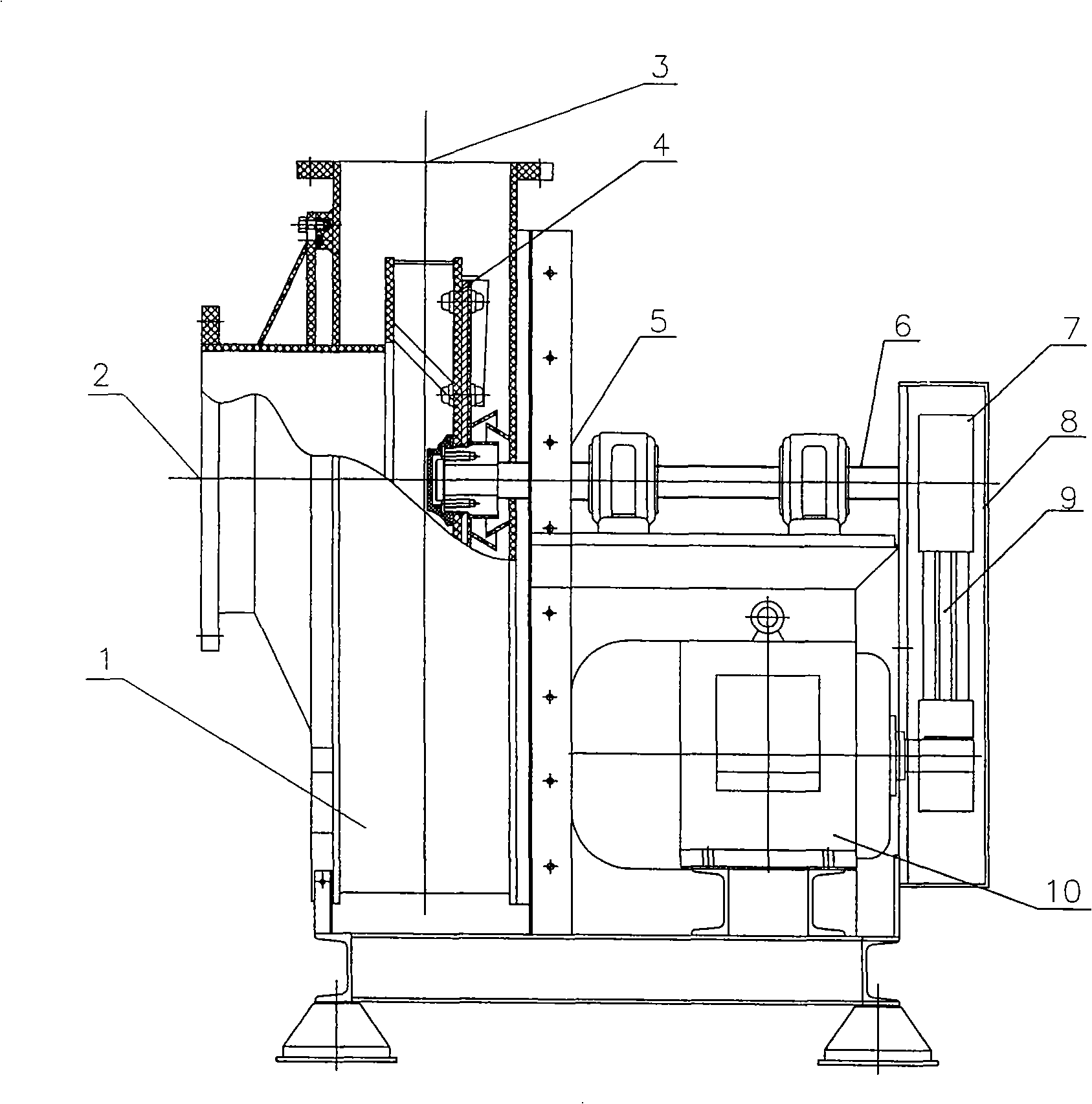

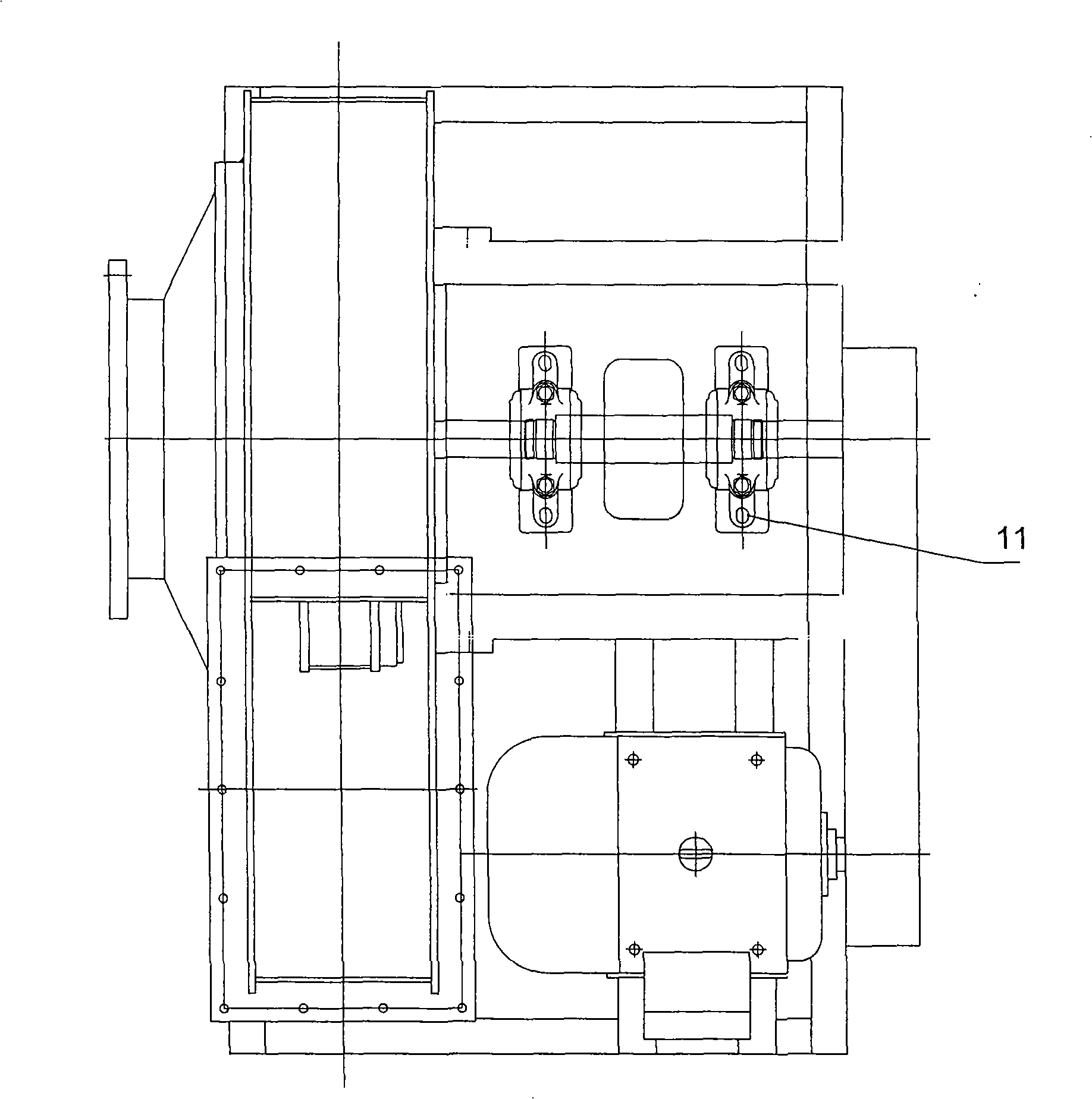

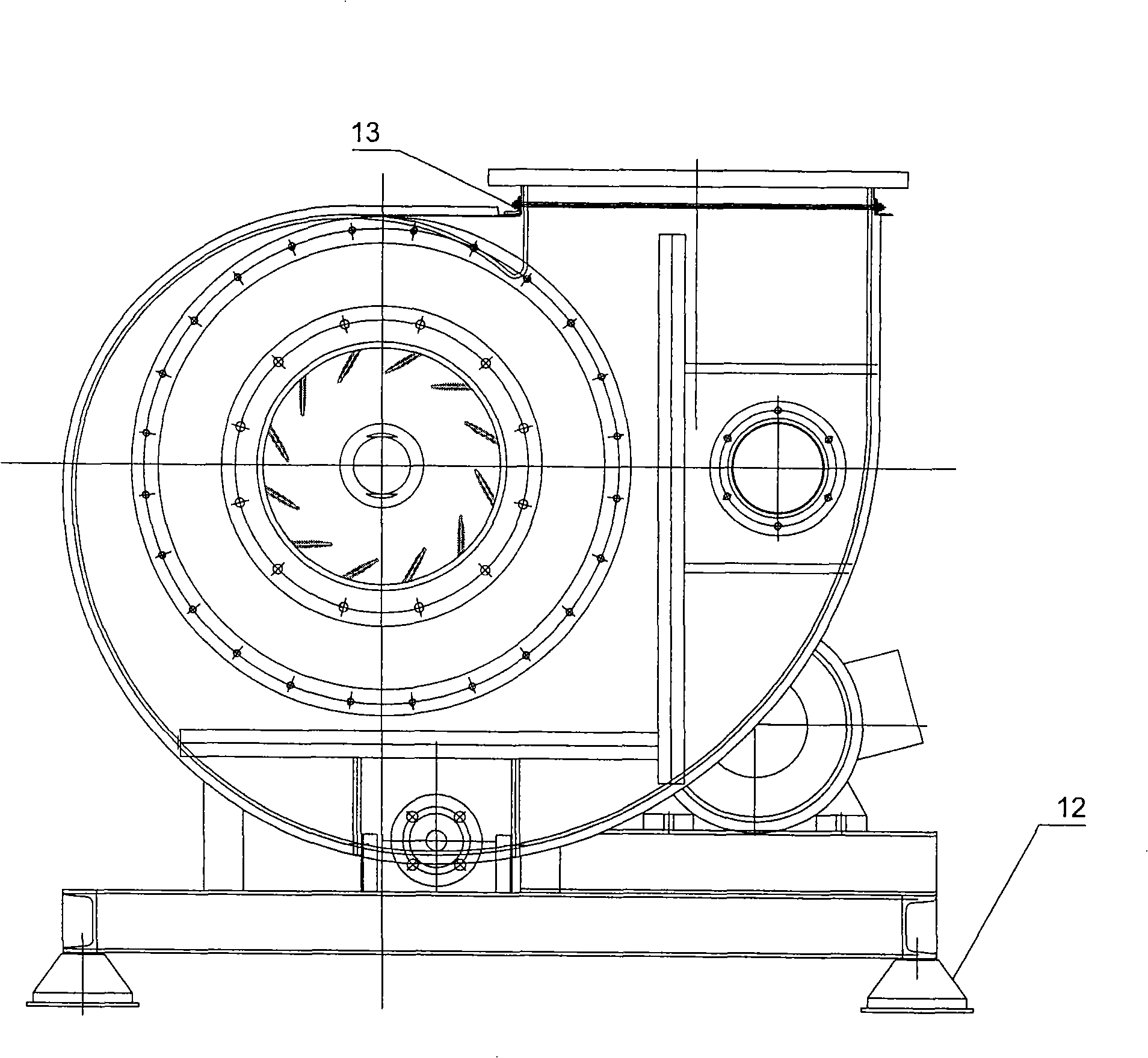

[0019] The large-scale high and medium pressure all-plastic centrifugal fan of the present invention is composed of a fan casing 1, an impeller 4, a wheel hub, a transmission device and a frame. The fan casing 1 is volute-shaped and is composed of an air inlet 2 and an air outlet 3, and has an impeller 4 inside. The transmission device is connected to the pulley 7 by the motor 10 to drive the transmission shaft 6 to connect to the impeller 4 to rotate simultaneously. The air inlet 2 is in the axial direction of the transmission shaft 6, the air outlet 3 is on the upper part of the fan, and is covered with a protective cover 13 to prevent foreign matter from entering, a bearing seat 11 is fixed on the bracket 5, a belt 9 is hung on the pulley 7, and the outer cover belt cover 8, The whole blower fan is placed on the base with shock absorber 12.

[0020] The centrifuga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com