Gas sensor based on gas discharge spectral analysis and method for testing gas thereof

A gas sensor and spectral analysis technology, applied in electrical excitation analysis, material excitation analysis, etc., can solve problems such as poor selectivity, mixed gas sensitivity and detection accuracy that cannot reach gas discharge spectral analysis, and achieve detection methods and hardware. Simplification, improved energy conversion efficiency, effect of high light radiant intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

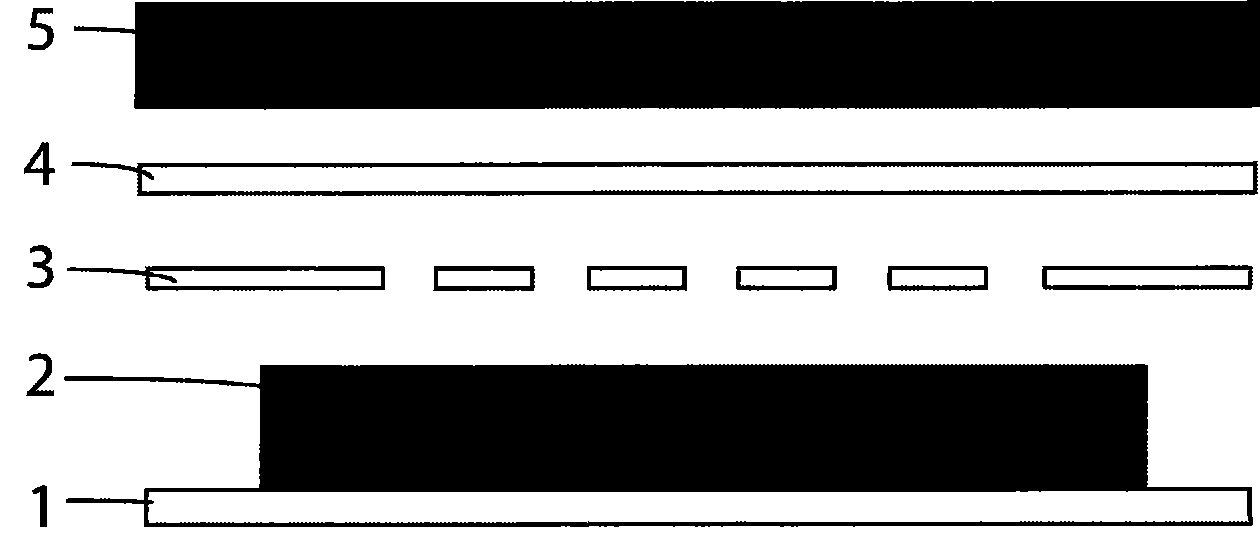

[0040] As shown in Figure 1, a gas sensor based on gas discharge spectroscopy includes a polarized electrode 1, a grid electrode 3, a bandpass filter 4 and a photosensitive device 5;

[0041] The grid electrode 3 and the bandpass filter 4 are between the polarizing electrode 1 and the photosensitive device 5;

[0042] The grid electrode 3 and the bandpass filter 4 are arranged on two different substrates with a gas gap between them;

[0043] The photosensitive device 5 and the bandpass filter 4 are either arranged on two different substrates with a gas gap between them;

[0044] On the surface of the polarizing electrode 1 facing the grid electrode 3, a conductive or semiconducting one-dimensional nanomaterial is arranged as the electrode material 2 of the polarizing electrode, and the electrode material 2 of the polarizing electrode is not prepared by an in-situ manufacturing process. A multi-layer metal layer is arranged between the electrode material of the polarized elect...

Embodiment 2

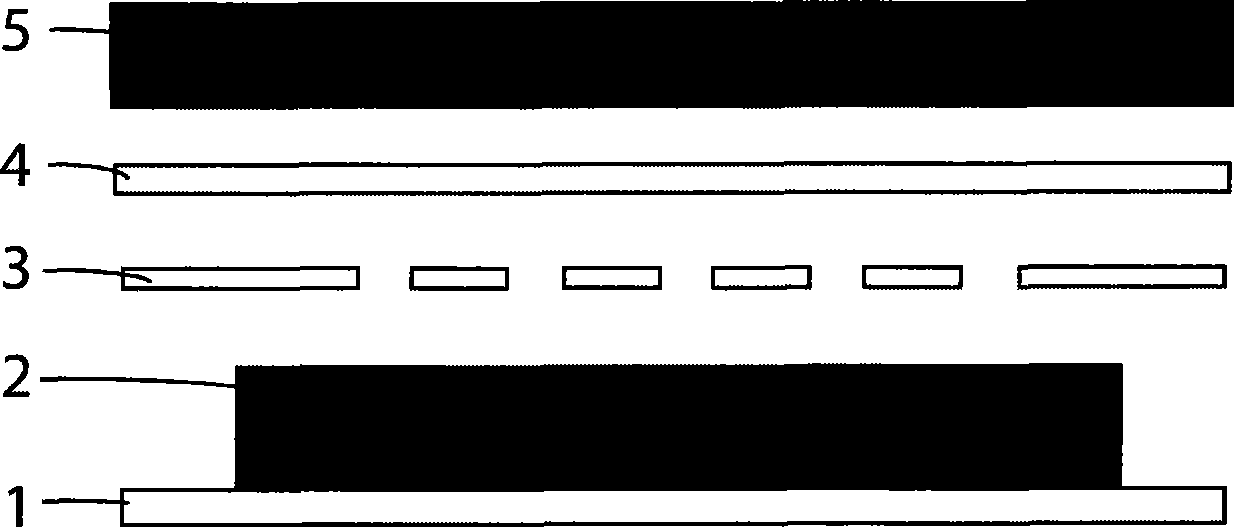

[0062] As shown in Figure 2, a gas sensor based on gas discharge spectroscopy includes a polarized electrode 1, a grid electrode 3, a bandpass filter 4 and a photosensitive device 5;

[0063] The grid electrode 3 and the bandpass filter 4 are between the polarizing electrode 1 and the photosensitive device 5;

[0064] The grid electrode 3 and the bandpass filter 4 are arranged on a substrate;

[0065] The photosensitive device 5 and the bandpass filter 4 are arranged on two different substrates with a gas gap between them;

[0066] On the surface of the polarizing electrode 1 facing the grid electrode 3, a conductive or semiconducting one-dimensional nanomaterial is arranged as the electrode material 2 of the polarizing electrode. The electrode material 2 of the polarizing electrode is prepared by an in-situ manufacturing process. There is no metal layer between the polarized electrode material and the substrate;

[0067] The gas gap between the grid electrode 3 and the pola...

Embodiment 3

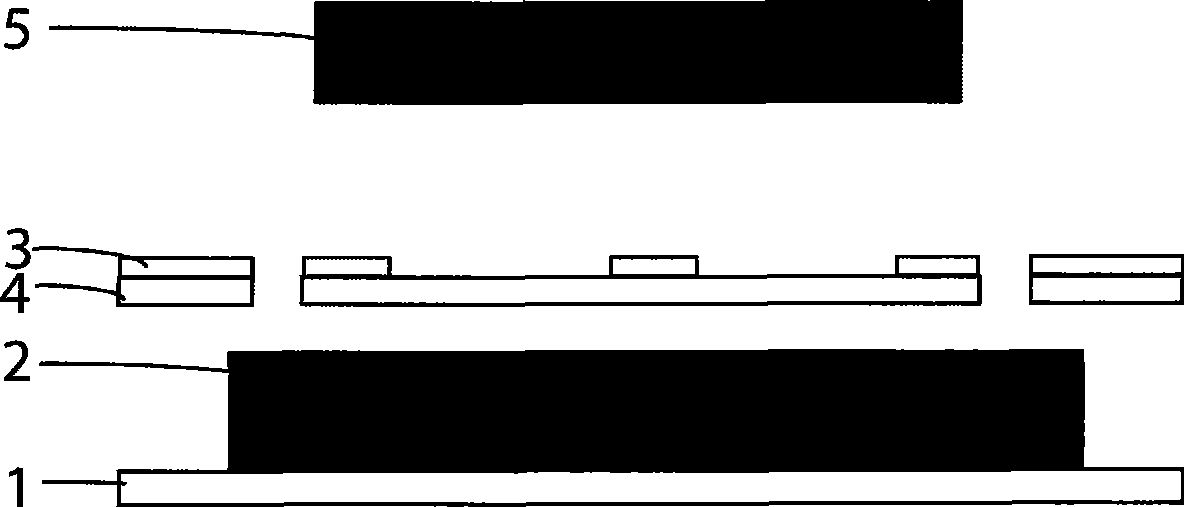

[0077] As shown in Figure 3, a kind of gas sensor based on gas discharge spectrum analysis, comprises polarized electrode 1, grid electrode 3, bandpass filter 4 and photosensitive device 5;

[0078] The grid electrode 3 and the bandpass filter 4 are between the polarizing electrode 1 and the photosensitive device 5;

[0079] The grid electrode 3 and the bandpass filter 4 are arranged on a substrate;

[0080] The photosensitive device 5 and the bandpass filter 4 are arranged on two different substrates with a gas gap between them;

[0081] On the surface of the polarizing electrode 1 facing the grid electrode 3, a conductive or semiconducting one-dimensional nanomaterial is arranged as the electrode material 2 of the polarizing electrode. The electrode material 2 of the polarizing electrode is prepared by an in-situ manufacturing process. There is no metal layer between the polarized electrode material and the substrate;

[0082] The gas gap between the grid electrode 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com