Combined speed regulating device for frequency changer of mine ventilator

A technology of speed regulating device and frequency converter, which is applied in the direction of output power conversion device, cooling/ventilation/heating transformation, circuit layout on support structure, etc. Larger, higher manufacturing costs and other issues, to achieve the effect of improved work stability and reliability, wide range of air volume adjustment, and reliable starting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

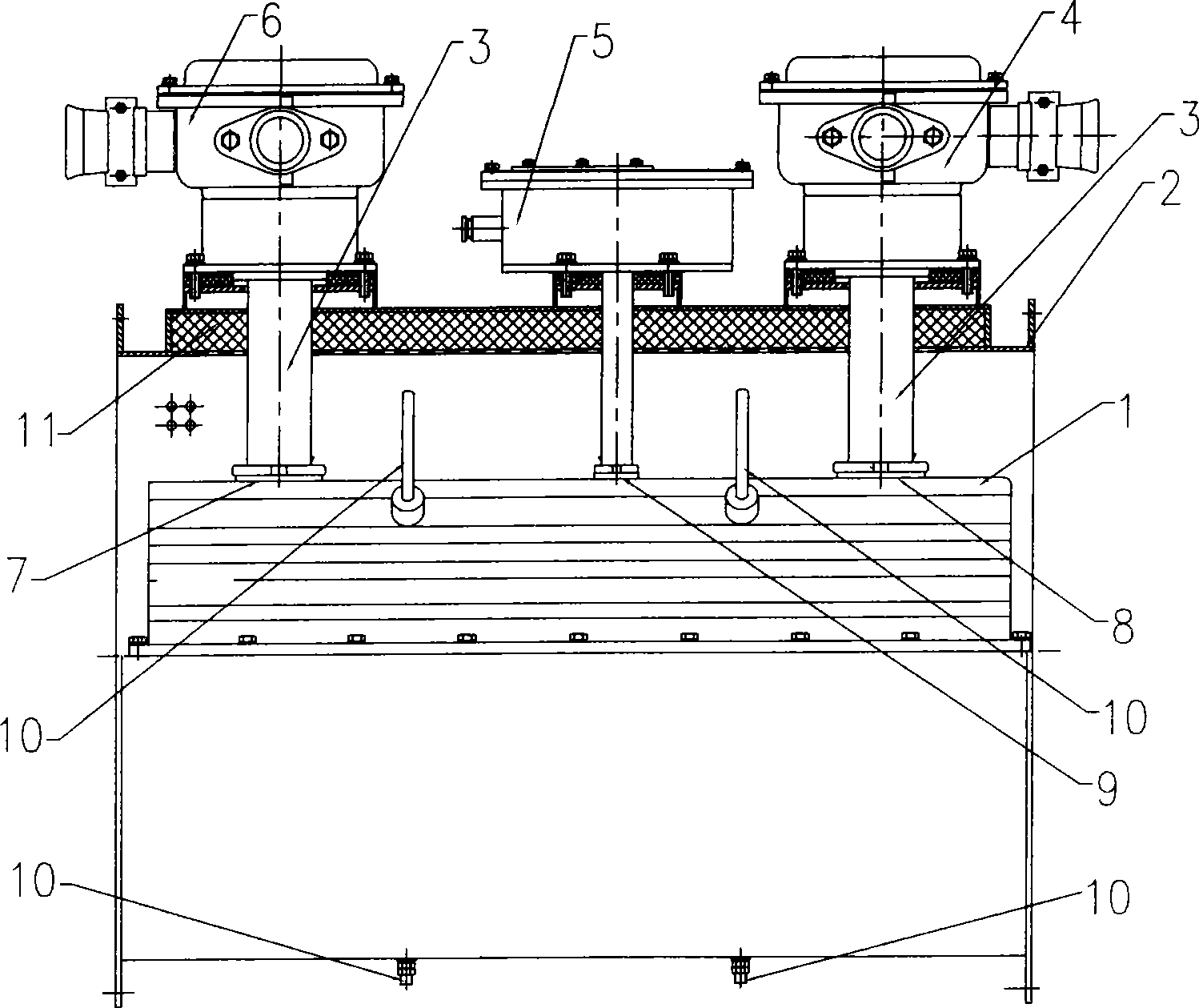

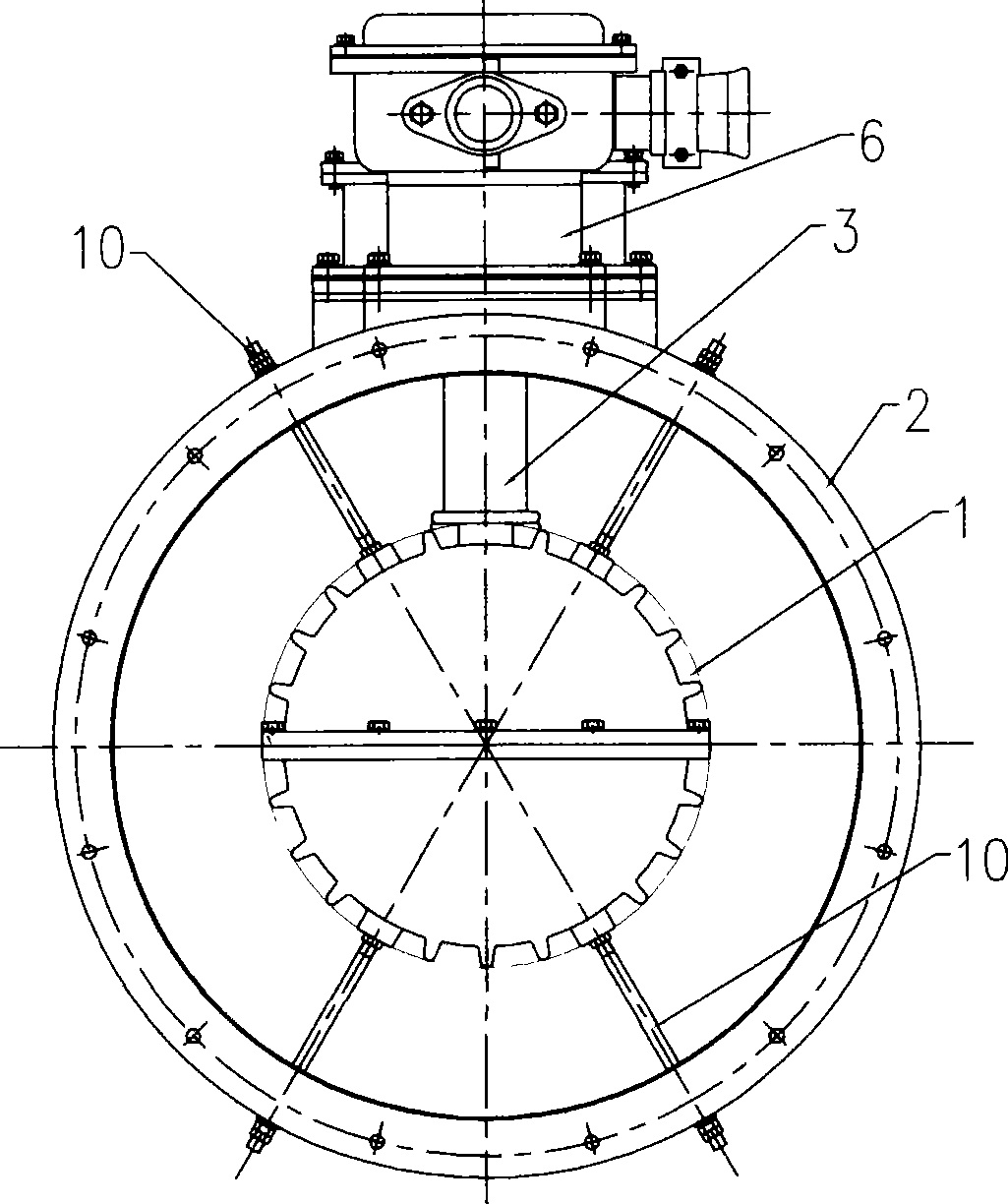

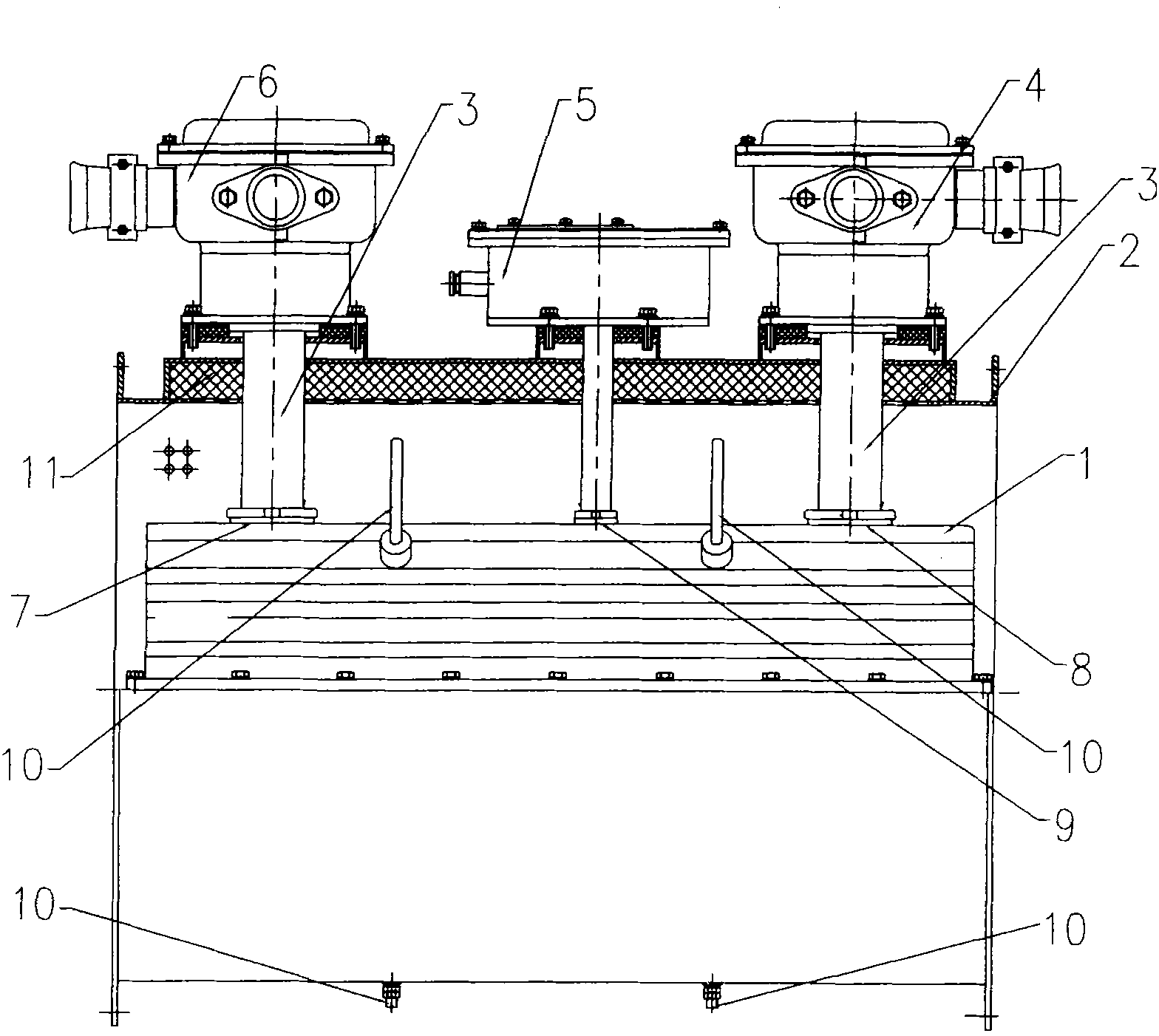

[0020] Embodiment 1, the present invention consists of two half-shells connected and fixed by the flameproof joint surface, and the two ends are closed to form a cylindrical inverter body 1, which is arranged between the connecting surfaces of the two half-shells. There is an explosion-proof joint surface, the inverter body 1 is installed in the center of the cross-section of the inverter fan duct 2, and a support connection device 10 is arranged between the inverter body 1 and the inverter fan cylinder 2. The support connection device 10 in the present invention can be used. Supporting members such as connecting screws, connecting struts or connecting struts are used. The wall of the inverter body 1 is provided with a connection cable connection hole, and the inverter fan duct 2 is provided with a connection box connection hole corresponding to the position of the connection cable connection hole provided on the inverter body 1. The connection wires of the junction box outsid...

Embodiment 2

[0021] In Embodiment 2, the present invention can also be fitted with a filter in the frequency converter body 1 . By installing the filter, the conducted interference and emission interference generated by the inverter can be reduced, the voltage and current harmonic interference can be resisted, the power quality can be improved, the external interference of the frequency conversion device can be reduced, and the reliability of the safe use of other electronic devices in the well can be improved. see figure 1 and figure 2 , and the rest are the same as in Example 1.

Embodiment 3

[0022] Embodiment 3, the present invention can also install a filter device composed of a magnetic ring in the wiring pipe device 3, and convert the high frequency component into heat loss by using the eddy current loss of the magnetic ring to the high frequency signal. Therefore, the magnetic ring actually absorbs the high-frequency components, which can also be called an absorption filter. It no longer needs to install special filters at the incoming and outgoing ends of the frequency conversion speed control device, which reduces the space of the inverter body and saves materials. see figure 1 and figure 2 , and the rest are the same as the above-mentioned embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com