Power supply method for asynchronous motor

A power supply method and asynchronous motor technology, applied in the direction of AC motor control, electrical components, control systems, etc., can solve the problems that are not conducive to the realization of an all-in-one machine, the volume of capacitors is large, and the number of capacitors is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

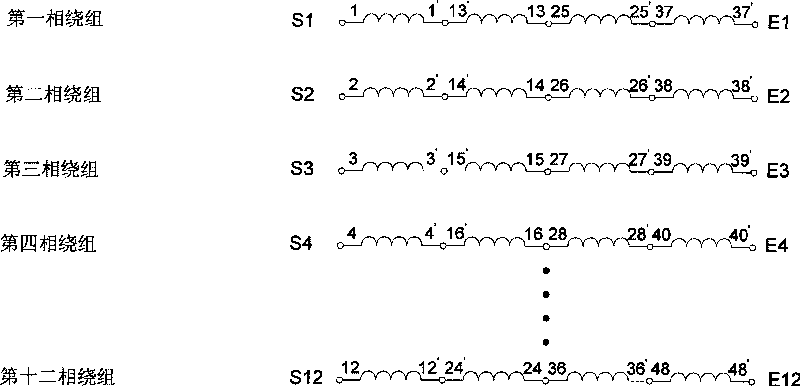

[0033] refer to figure 1 , assuming that the asynchronous motor stator has 48 slots, which are recorded as 1st, 2nd, 3rd, ... 48th along the circumferential direction. The stator winding adopts double-layer stacking, so there are 48 coils in total, of which there are 12 coils in each pole. It is now stipulated that the coil is represented by the slot number where the upper side of the coil is located. Coils 1-12 belong to the first pole, and coils 13- 24 belongs to the second pole, coils 25-36 belong to the third pole and coils 37-48 belong to the fourth pole. Use 1 and 1' to denote the head and tail of the first coil respectively, and the rest of the coils are similar. Now 48 coils are connected into 12 phases, and S and E are used to represent the head end and tail end of each phase respectively in the figure.

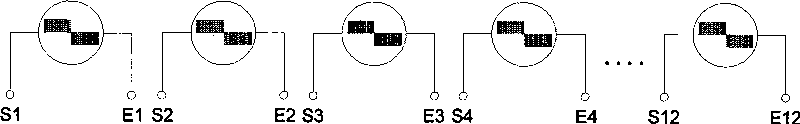

[0034] The inverter has 12 outputs, such as figure 2 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com