Dielectric fluid for electric discharge machining a non electrically conductive material

A technology of dielectric liquid and conductive material, applied in the field of dielectric liquid for EDM ablation, can solve problems such as harmful health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

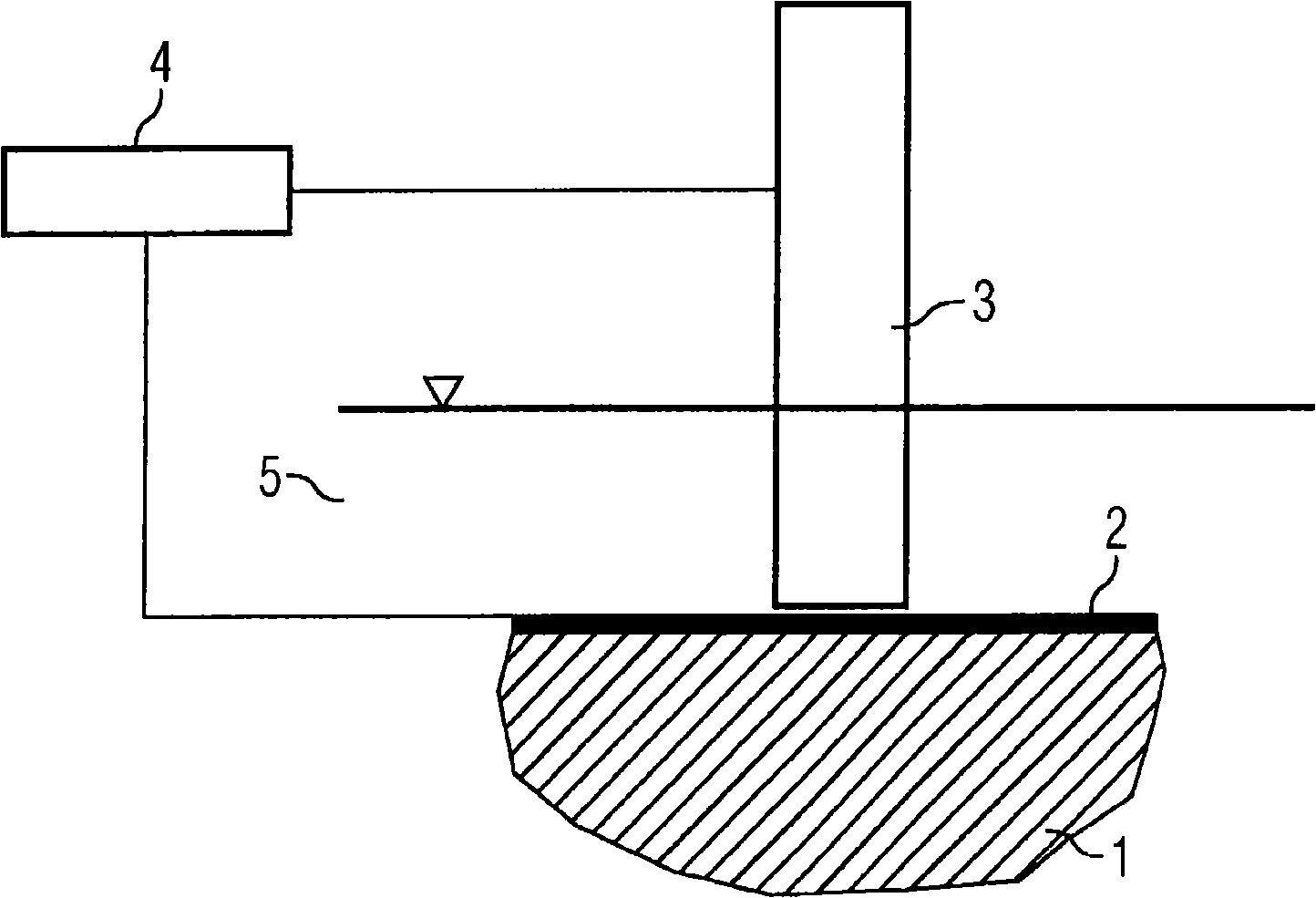

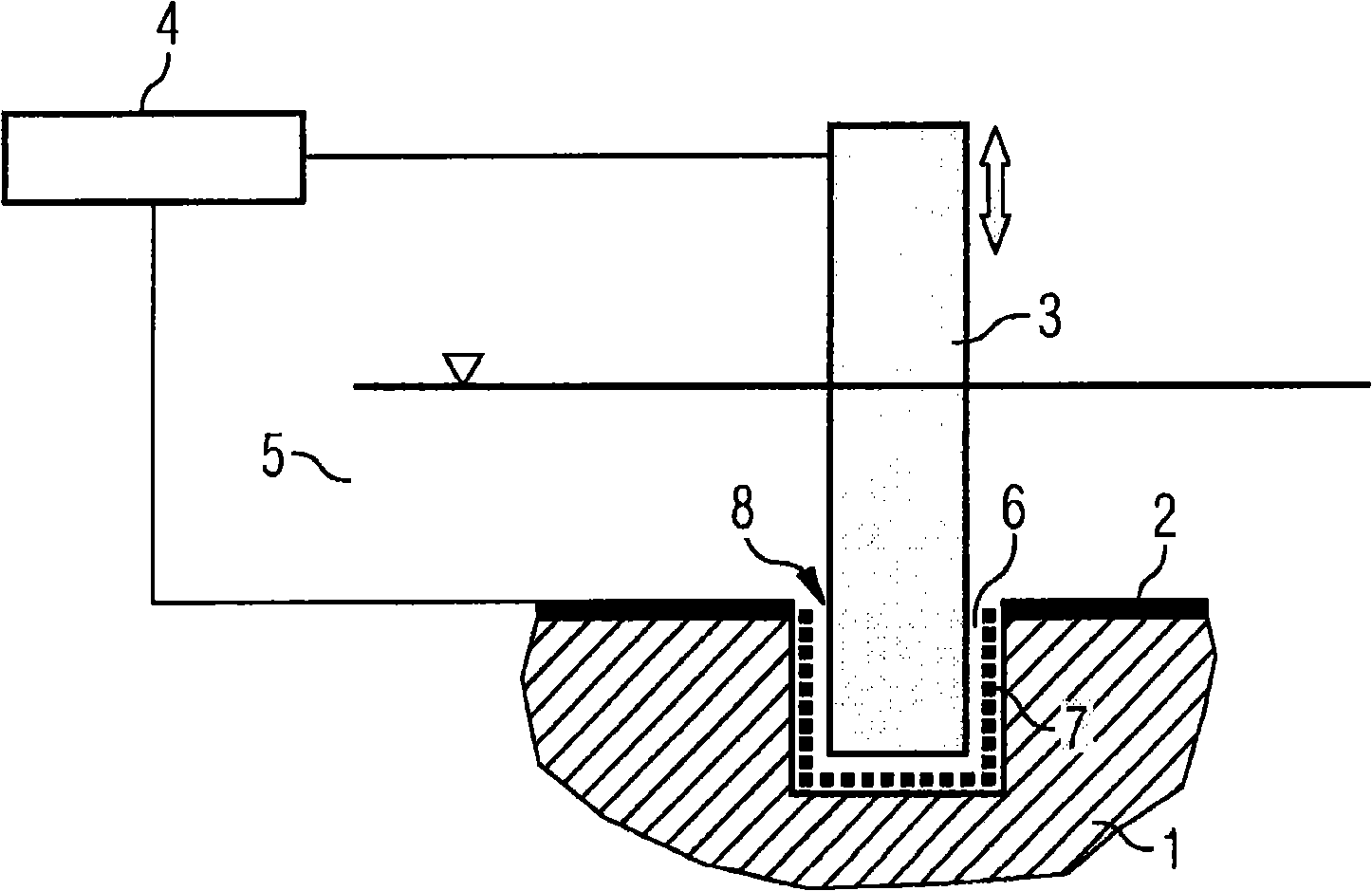

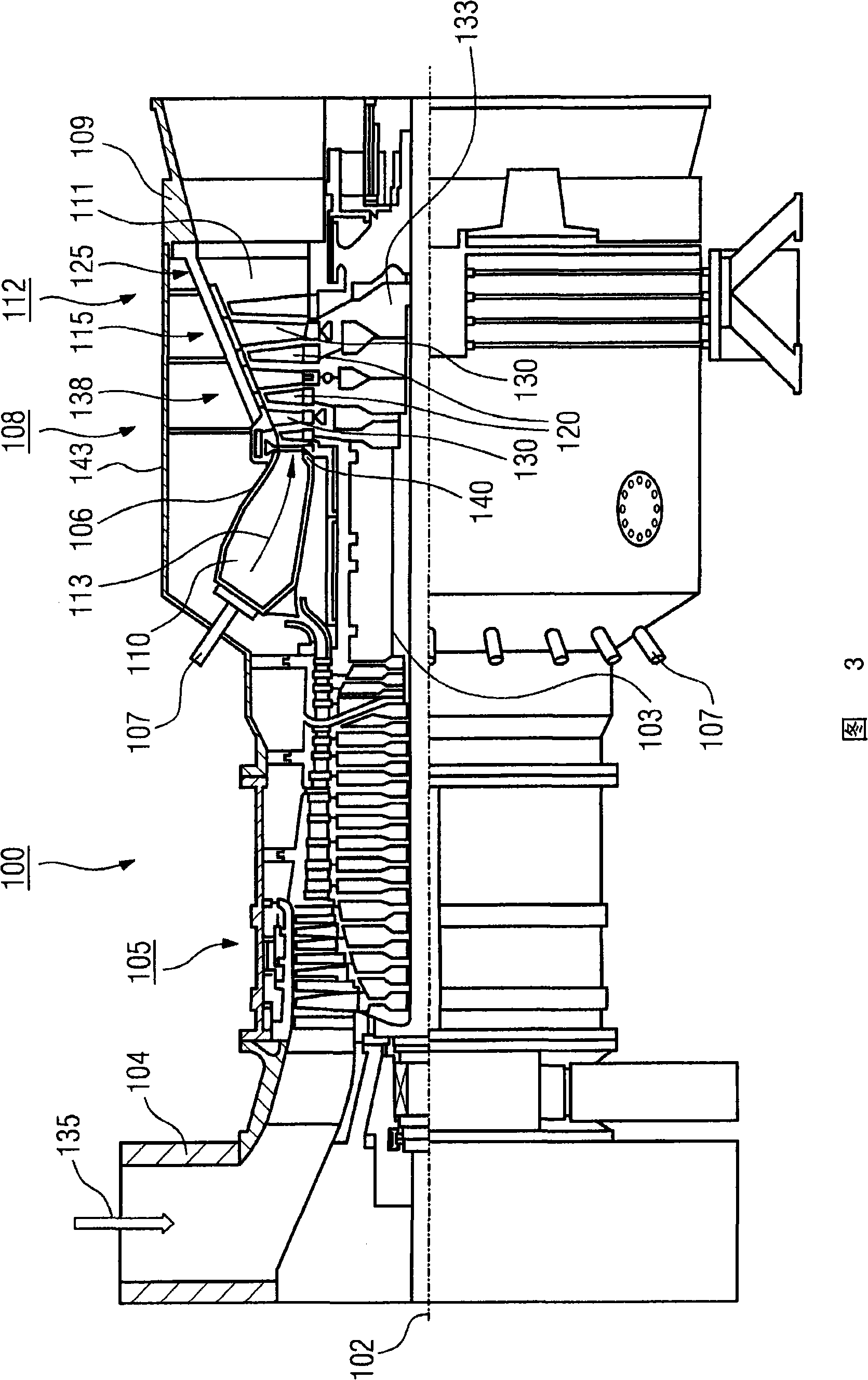

[0025] figure 1 Shows a method arrangement for implementing the electrical discharge ablation machining of non-conductive materials according to the present invention, the non-conductive material here in the form of component 1, which is made of ceramics containing zirconia production. The component 1 may be a part of a turbine 100 (Figure 3) or a combustion chamber, such as a rotor blade 120 (Figures 3, 4) or a guide vane 130 (Figures 3, 4). It is also possible that a non-conductive material is, for example, a coating of a turbine blade, where it can be made into a thermal insulation layer.

[0026] A conductive material in the form of a graphite layer is flatly coated on the component 1 as the auxiliary electrode 2. Alternatively, organic compounds or metals, such as zirconium, can also be used as the conductive substance.

[0027] The auxiliary electrode 2 and the working electrode 3 are electrically conductively connected to a generator 4 which applies a suitable voltage to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com