Meat product improver

A quality improver, meat product technology, applied in food preservation, food preparation, meat/fish preservation and other directions, can solve the problems of inability to meet, can not completely inhibit the growth of microorganisms, short fresh-keeping period of cooled meat, etc., to improve water retention performance , The effect of reducing cooking loss and strong preservation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Get 55g of sodium chloride, 20g of dry glucose syrup powder, 5g of sodium citrate, 15g of sodium acetate, 5g of sodium erythorbate, grind them and mix to obtain the meat product quality improver of the present invention. When in use, add water to the above-mentioned improver to prepare a treatment solution with a concentration of 8-10%, dip or inject the treatment solution into the cooled meat, marinate for 25-30 minutes, and add 20-23g of the improver to the meat product / kg. The treated product was stored in an environment of 0-4°C. Compared with the control group, the cooking loss was reduced by 30%, the storage loss was reduced by 5%, the product yield increased by 30%, and the shelf life of the product was extended by 3 days compared with the same period last year.

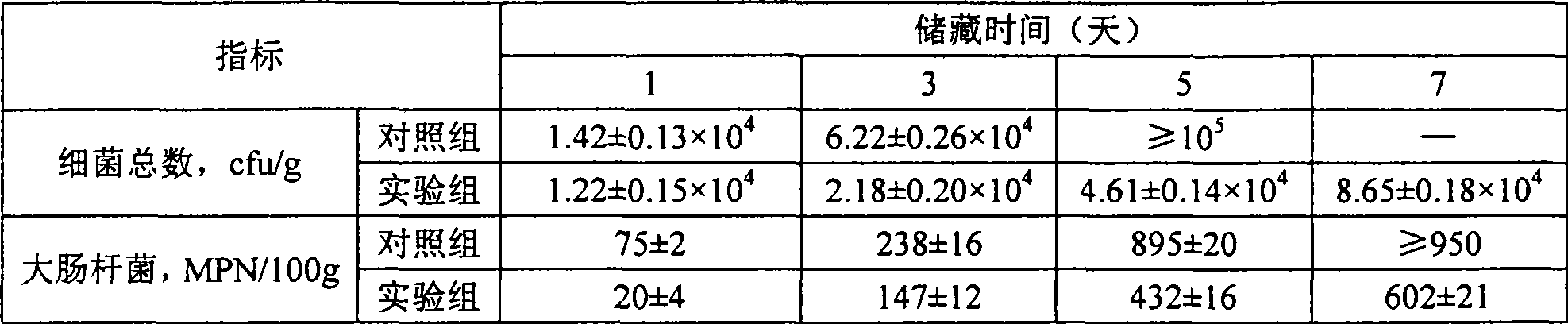

[0023] Table 1 The results of the changes in the number of microorganisms during storage in Example 1

[0024]

Embodiment 2

[0026] Get sodium chloride 60g, dry glucose syrup powder 15g, sodium citrate 15g, sodium acetate 5g, mix after they pulverize and obtain the meat product quality improver of the present invention. When in use, add water to the above-mentioned improver to prepare a treatment solution with a concentration of 8-10%, dip or inject it into the cooled meat, and marinate for 25-30 minutes. The amount of the improver relative to the meat product is 20-23g / kg. The treated product was stored in an environment of 0-4°C. Compared with the control group, the cooking loss was reduced by 40%, the storage loss was reduced by 8%, the product yield was increased by 40%, and the shelf life of the product was extended by 4 days compared with the same period last year.

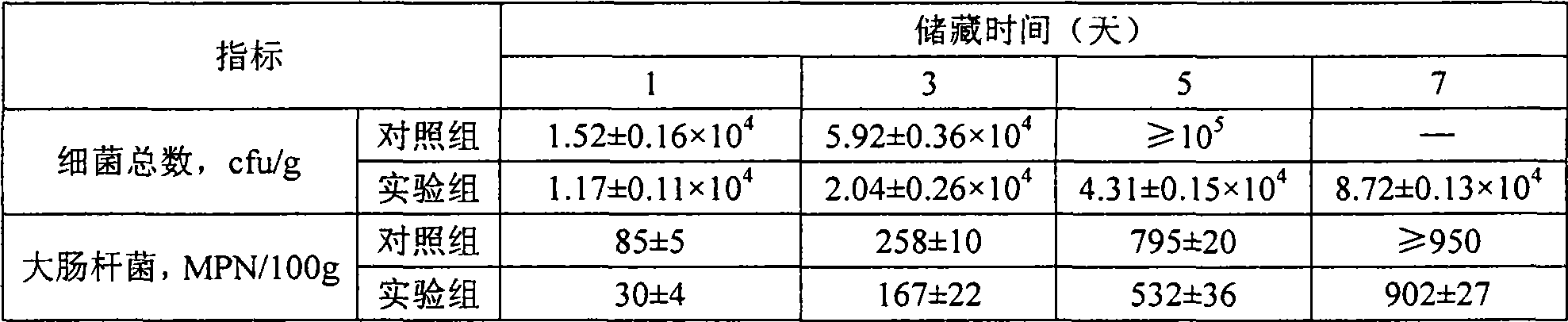

[0027] Table 2 The results of microbial quantity changes during storage in Example 2

[0028]

Embodiment 3

[0030] Get 65g of sodium chloride, 10g of dry glucose syrup powder, 10g of sodium citrate, 10g of sodium acetate, 5g of sodium erythorbate, grind them and mix to obtain the meat product quality improver of the present invention. When in use, add water to the above-mentioned improver to prepare a treatment solution with a concentration of 8-10%, dip or inject it into the cooled meat, and marinate for 25-30 minutes. The amount of the improver relative to the meat product is 20-23g / kg. The treated product was stored in an environment of 0-4°C. Compared with the control group, the cooking loss was reduced by 40%, the storage loss was reduced by 10%, the product yield was increased by 50%, and the shelf life of the product was extended by 5 days compared with the same period last year.

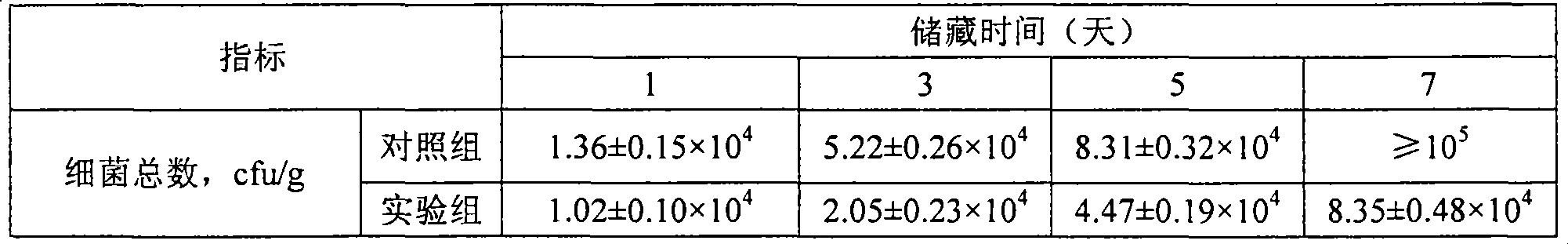

[0031] Table 3 The results of the changes in the number of microorganisms during the storage period of Example 3

[0032]

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com