Constant-pressure storage type high-pressure carbon dioxide extinguishing device with built-in evaporator

A high-pressure carbon dioxide and fire extinguishing device technology, which is applied in fire rescue and other fields, can solve the problems of low filling density, high initial pressure, and low initial pressure, and achieve the goal of improving refrigeration efficiency, reducing pressure bearing capacity, and improving reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

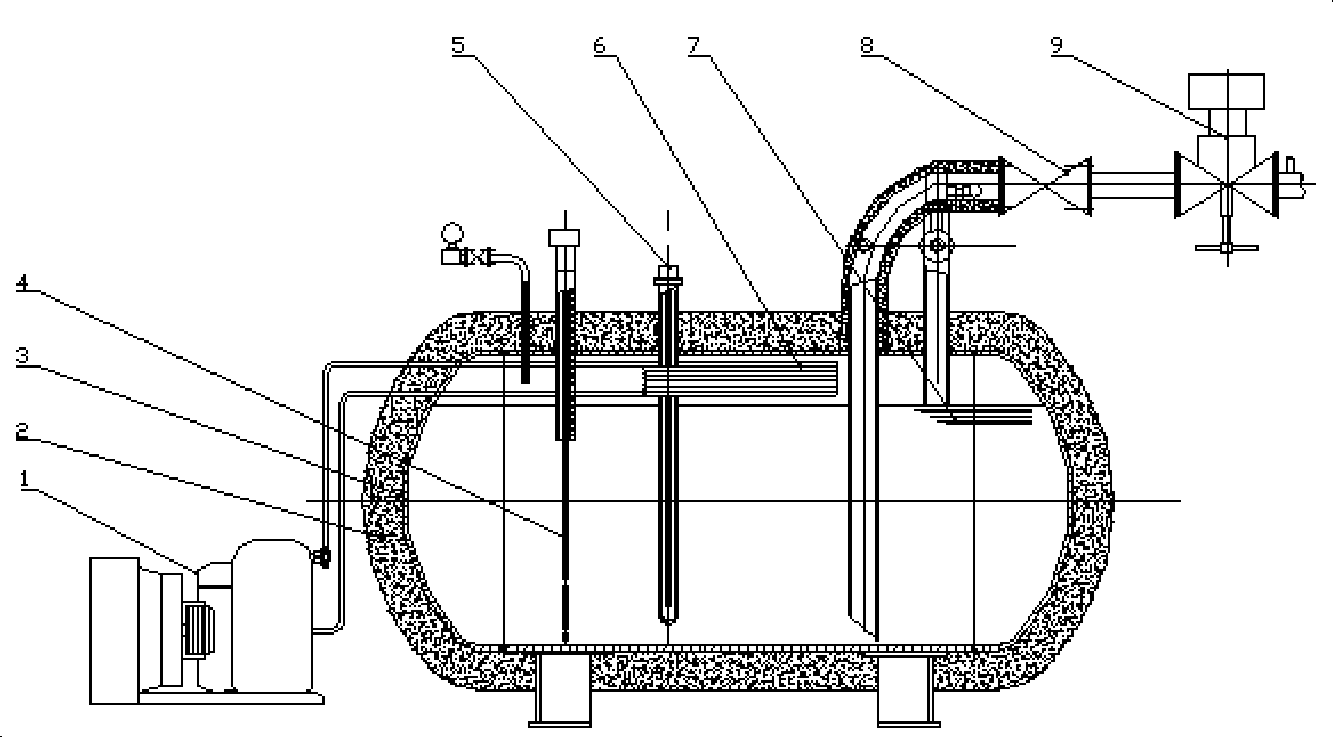

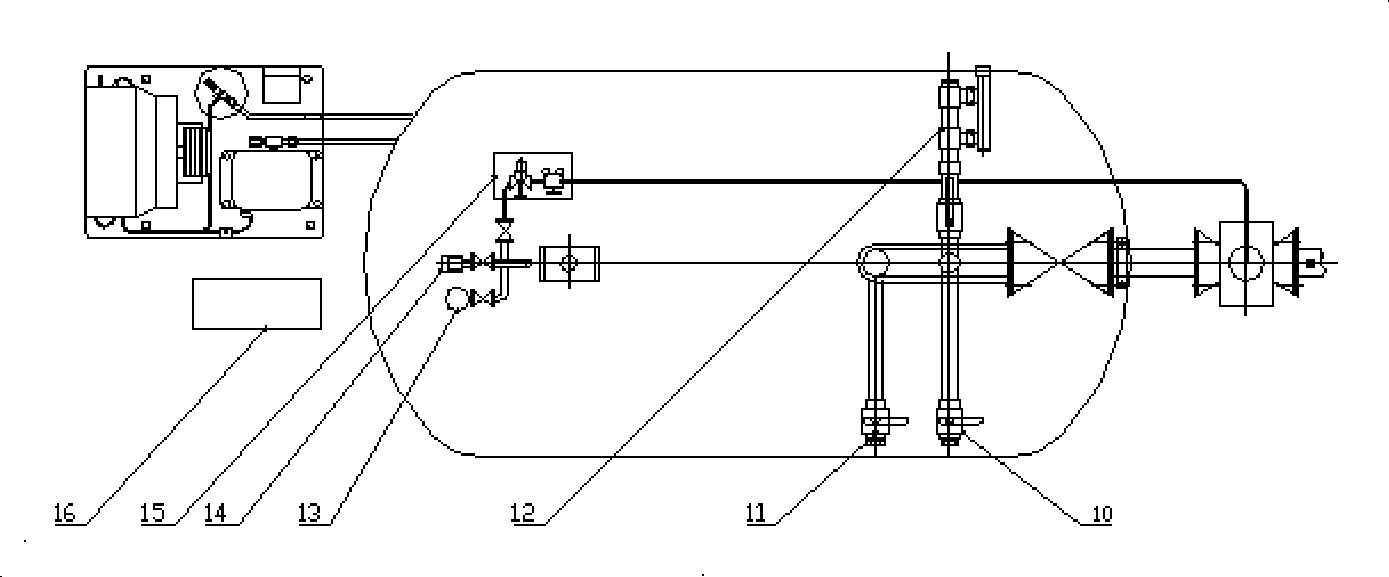

[0012] Below in conjunction with the accompanying drawings and specific implementation methods, the specific embodiments and working principles of the constant pressure storage type high-pressure carbon dioxide fire extinguishing device with a built-in evaporator of the present invention will be further explained and described in detail:

[0013] The structure of the constant-pressure storage type high-pressure carbon dioxide fire extinguishing device with built-in evaporator of the present invention is as follows: figure 1 , figure 2 Shown: Mainly composed of refrigeration unit 1, heat insulation layer 2, storage container 3, liquid level sensor 4, heating component 5, evaporator 6, fire extinguishing agent 7, inspection valve 8, master control valve 9, balance valve 10, filling valve 11. Safety pressure relief device 12, pressure gauge 13, pressure sensor 14, pneumatic control device 15, and controller 16. Wherein the evaporator 6 is located in the storage container 3 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com