A kind of gas-soluble sealing emulsion and preparation method thereof

An emulsion and gas-soluble technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of plugging failure and slow plugging, and achieve the advantages of preventing crack opening, good pressure bearing performance, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

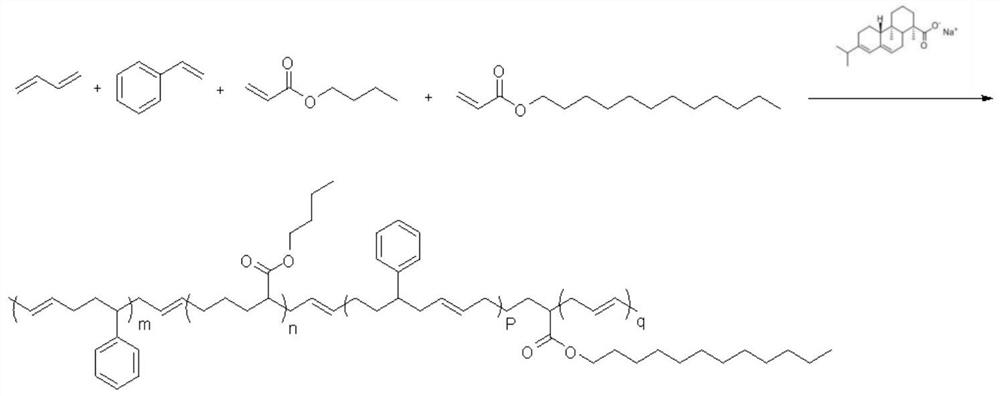

Method used

Image

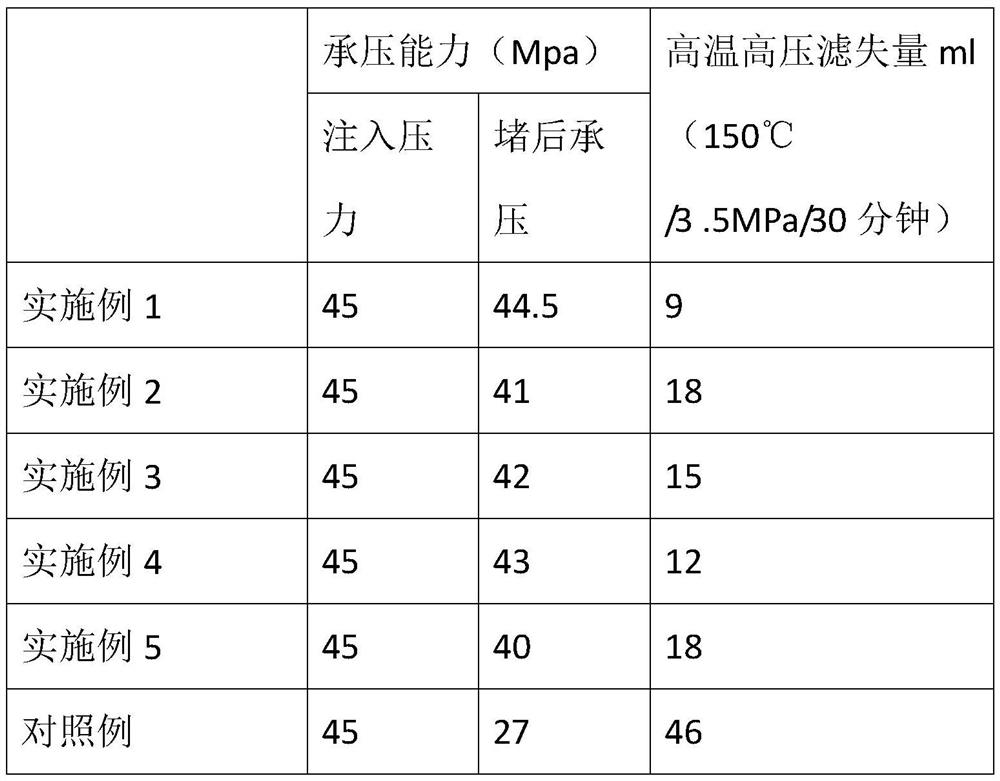

Examples

Embodiment 1

[0041] 210 grams of deionized water, 3 grams of sodium dodecylsulfonate, and 0.03 grams of EDTA sodium salt were sequentially added to a 1000 mL four-necked flask, and stirred at 240 rpm to form a solution. Remove the air under 0.09MPa vacuum and replace with nitrogen 3 times.

[0042] Add 140 grams of butadiene and 60 grams of styrene to this solution in sequence, add 0.24 grams of initiator azobisisobutyronitrile after nitrogen replacement, heat up to 45 degrees under stirring for 8 hours, and the reaction solution drops to room temperature.

[0043] 10 grams of butyl acrylate and 10 grams of lauryl acrylate were added to the reaction system, and 0.24 grams of initiator azobisisobutyronitrile was added after nitrogen replacement again. The reaction was continued at 25° C. for 6 hours under nitrogen flow. Gel chromatography detects that the monomer conversion rate is >99%, and the reaction is stopped.

[0044] Add 0.4 g of butyl 3-mercaptoacrylate to the reaction liquid, cont...

Embodiment 2

[0048] 225 grams of deionized water, 3 grams of sodium dodecylsulfonate, 3 grams of disproportionated sodium abietate, and 0.03 grams of acetylacetone were added to a 1000 mL four-necked flask in sequence, and stirred at 240 rpm to form a solution. Remove the air under 0.09MPa vacuum and replace with nitrogen 3 times.

[0049] Add 160 grams of butadiene and 60 grams of styrene to this solution successively, add 0.3 grams of initiator benzoyl peroxide after nitrogen replacement, heat up to 55 degrees under stirring and react for 6 hours. The reaction solution was cooled to room temperature.

[0050] 20 grams of butyl acrylate and 20 grams of lauryl acrylate were added to the reaction system, and 0.3 grams of initiator benzoyl peroxide was added after nitrogen replacement again. The reaction was continued at 25° C. for 8 hours under nitrogen flow. Gel chromatography detects that the monomer conversion rate is >99%, and the reaction is stopped.

[0051] 0.6 g of isooctyl 3-mer...

Embodiment 3

[0055] 420 grams of deionized water, 3 grams of disproportionated sodium abietate, 3 grams of sodium petroleum alkyl sulfonate, and 0.06 grams of chitosan were sequentially added to a 2000 mL four-necked flask, and stirred at 240 rpm to form a solution. Remove the air under 0.09MPa vacuum and replace with nitrogen 3 times.

[0056] Add 280 grams of butadiene and 140 grams of styrene to this solution successively, add 0.5 grams of initiator after nitrogen replacement, heat up to 45 degrees under stirring and react for 8 hours. The reaction solution was cooled to room temperature.

[0057] 20 grams of butyl acrylate and 20 grams of lauryl acrylate were added to the reaction system, and 0.5 grams of initiator was added after nitrogen replacement again, and the reaction was continued for 6 hours at 25 degrees under nitrogen flow. Gel chromatography detects that the monomer conversion rate is >99%, and the reaction is stopped. The initiator in the present embodiment is ferrous su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com