Wet land technique for deep purification of tail water of sewage plant

A technology for sewage plants and wetlands, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve mature technology and ensure thoroughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

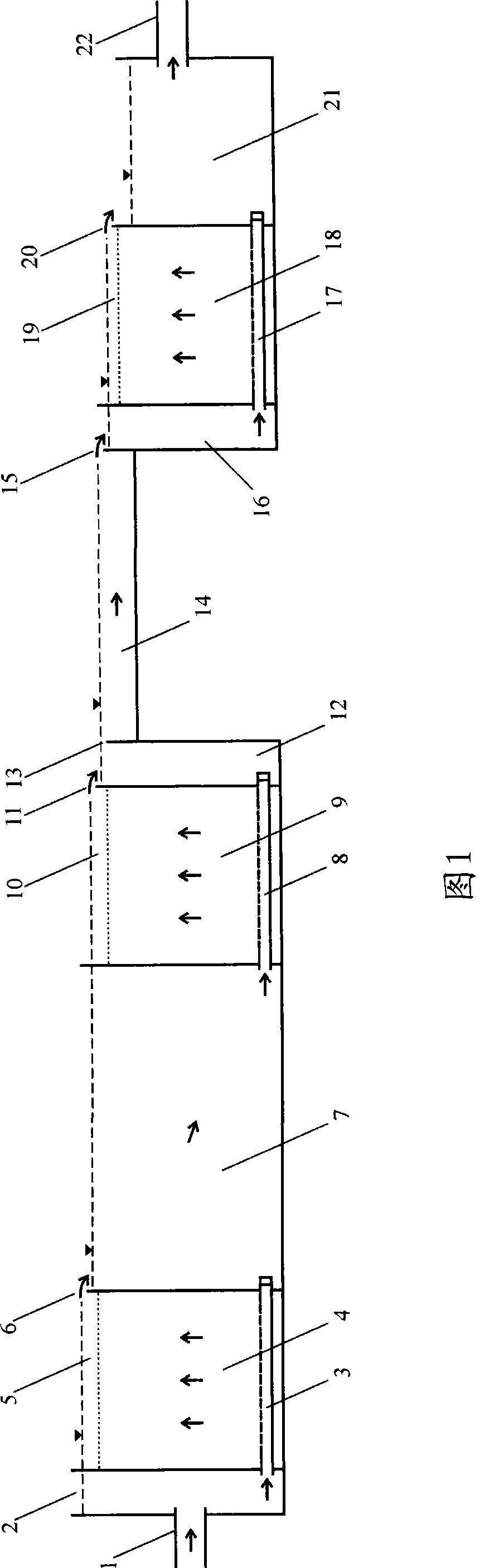

[0023] The present invention carries out engineering application according to the following steps:

[0024] 1. Pool masonry

[0025] (1) Build the pool body with mortar and rubble.

[0026] (2) Use cement mortar as anti-seepage treatment for the pool ridge.

[0027] (3) The anti-seepage treatment at the bottom of the pool is done with rolled composite soil.

[0028] 2. Pipe laying

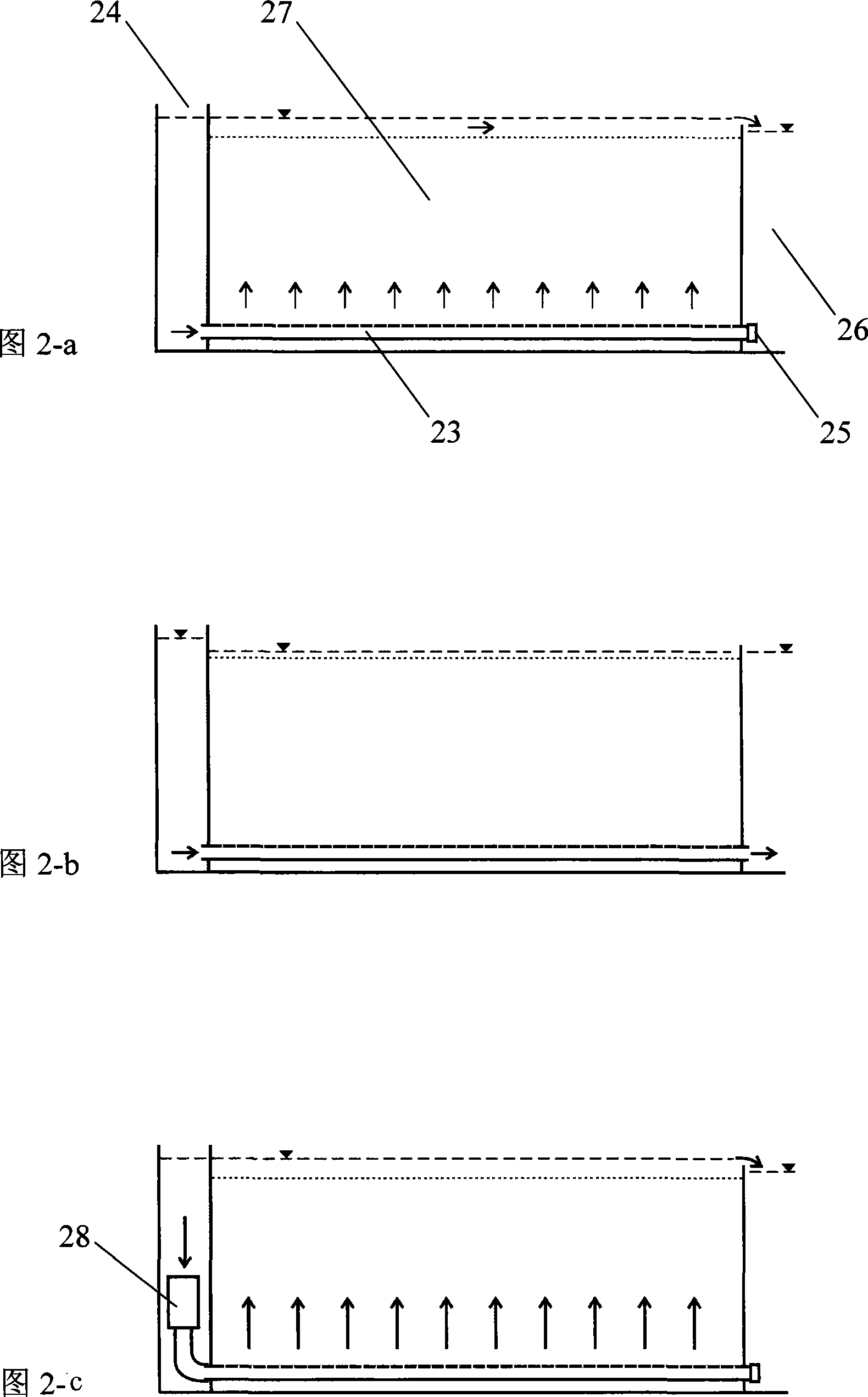

[0029] (1) Lay water distribution pipes at intervals of 0.5m at the bottom of limestone filters, vertical flow wetlands, and composite matrix filters.

[0030] (2) Bury the diversion pipe from the discharge outlet of the sewage plant to the distribution ditch of the limestone filter.

[0031] (3) Bury the outlet culvert from the ecological reoxygenation tank to the receiving river.

[0032] 3. Matrix filling

[0033] (1) Fill limestone gravel in the limestone filter tank, with a particle size of 20-30mm.

[0034] (2) Fill the vertical flow wetland with gravel, with a particle size of 20-30mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com