Acrylonitrile biopolymer spinning fluid having homogeneous chain structure and preparation thereof

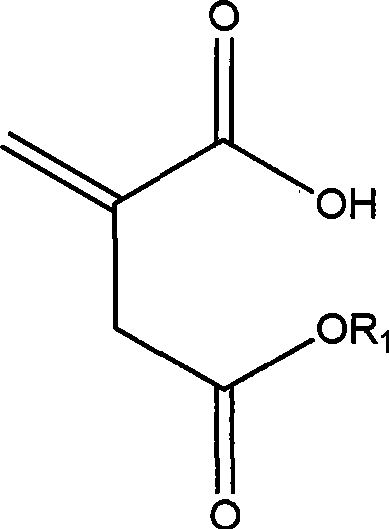

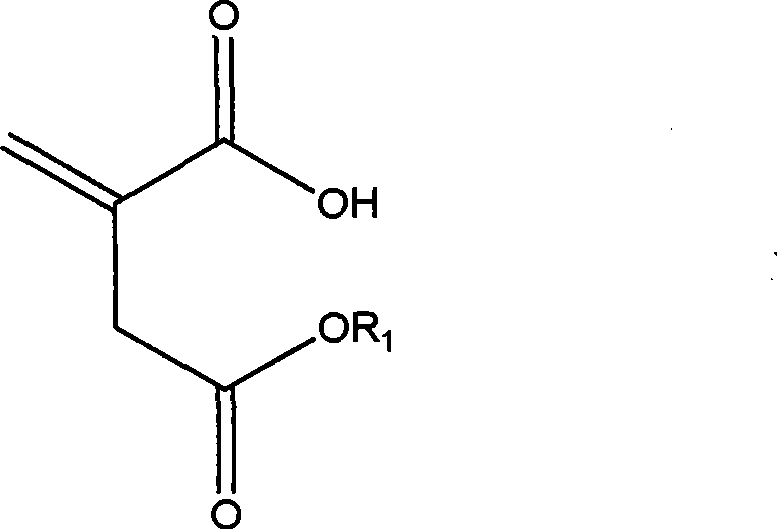

A technology of acrylonitrile binary copolymer spinning and acrylonitrile binary copolymer, which is applied in the field of preparation of acrylonitrile binary copolymer spinning solution, which can solve the problem of uneven distribution, difficulty in preparing high-performance carbon fiber spinning solution, etc. problem, to achieve the effect of controllable molecular weight and uniform chain structure of acrylonitrile copolymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 19.61 g of acrylonitrile, 0.40 g of β-MEI, 0.1601 g of azobisisoheptanonitrile, and 80 g of dimethyl sulfoxide, and add them into a reactor equipped with a condenser tube and a mechanical stirring device. Stirring and mixing at room temperature, nitrogen bubbling for 20 minutes, under nitrogen protection, polymerization reaction at 25° C. for 24 hours, and then removing residual monomers and bubbles to obtain a polyacrylonitrile-based binary copolymer spinning solution. The monomer conversion rate was 37.4%, the weight average molecular weight of the copolymer was 971,000, and the molecular weight distribution was 1.95.

Embodiment 2

[0021] Weigh 19.58 g of acrylonitrile, 0.41 g of β-MEI, 0.1601 g of azobisisoheptanonitrile, and 80 g of dimethyl sulfoxide, and add them into a reactor equipped with a condenser tube and a mechanical stirring device. Stirring and mixing at room temperature, nitrogen bubbling for 20 minutes, under nitrogen protection, polymerization at 45°C for 24 hours, and then removing residual monomers and bubbles to obtain a polyacrylonitrile-based binary copolymer spinning solution. The monomer conversion rate was 96.4%, the weight average molecular weight of the copolymer was 155,000, and the molecular weight distribution was 2.28.

Embodiment 3

[0023] Weigh 19.61 g of acrylonitrile, 0.40 g of β-MEI, 0.1602 g of azobisisoheptanonitrile, and 80 g of dimethyl sulfoxide, and add them into a reactor equipped with a condenser tube and a mechanical stirring device. Stirring and mixing at room temperature, nitrogen bubbling for 20 minutes, under nitrogen protection, polymerization reaction at 35°C for 6 hours, and then removing residual monomers and bubbles to obtain a polyacrylonitrile-based binary copolymer spinning solution. The monomer conversion rate was 40.0%, the weight average molecular weight of the copolymer was 291,000, and the molecular weight distribution was 2.07.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com