Preparation method of vinylene carbonate and method for converting the same to vinylene carbonate

A technology of vinylene carbonate and ethylene carbonate, applied to the preparation of ethylene monochlorocarbonate and its subsequent conversion into the field of vinylene carbonate, can solve problems such as insufficient purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

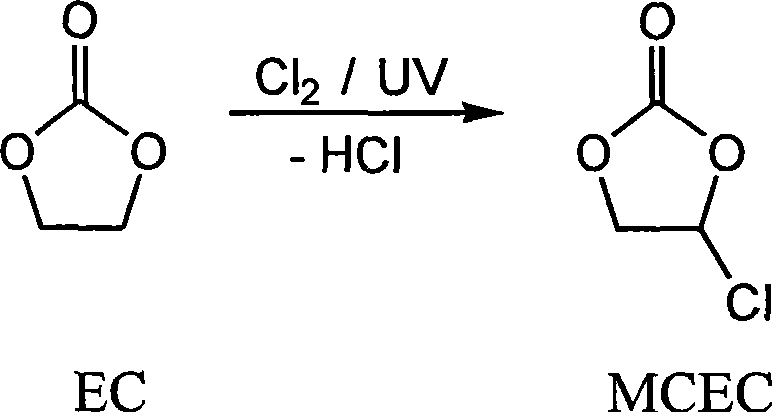

[0008] The reaction of ethylene carbonate (EC) with chlorine gas under ultraviolet light ("photochlorination") to form monochloroethylene carbonate (MCEC) is a radical substitution reaction and is described in Scheme 1 below.

[0009]

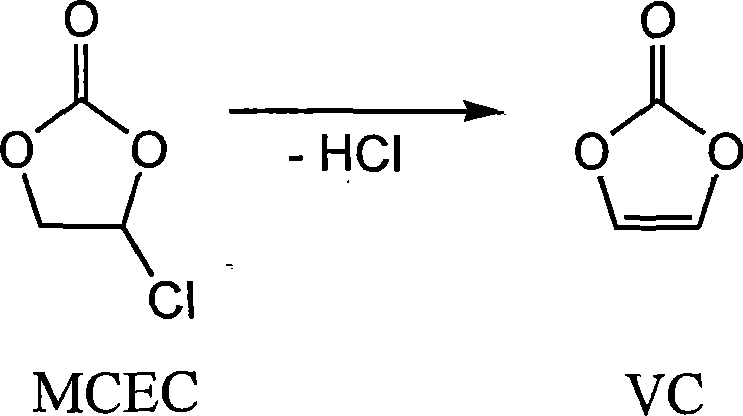

[0010] The following scheme 2 describes the conversion of ethylene monochlorocarbonate to vinylene carbonate (VC) by (ii) elimination of hydrogen chloride.

[0011]

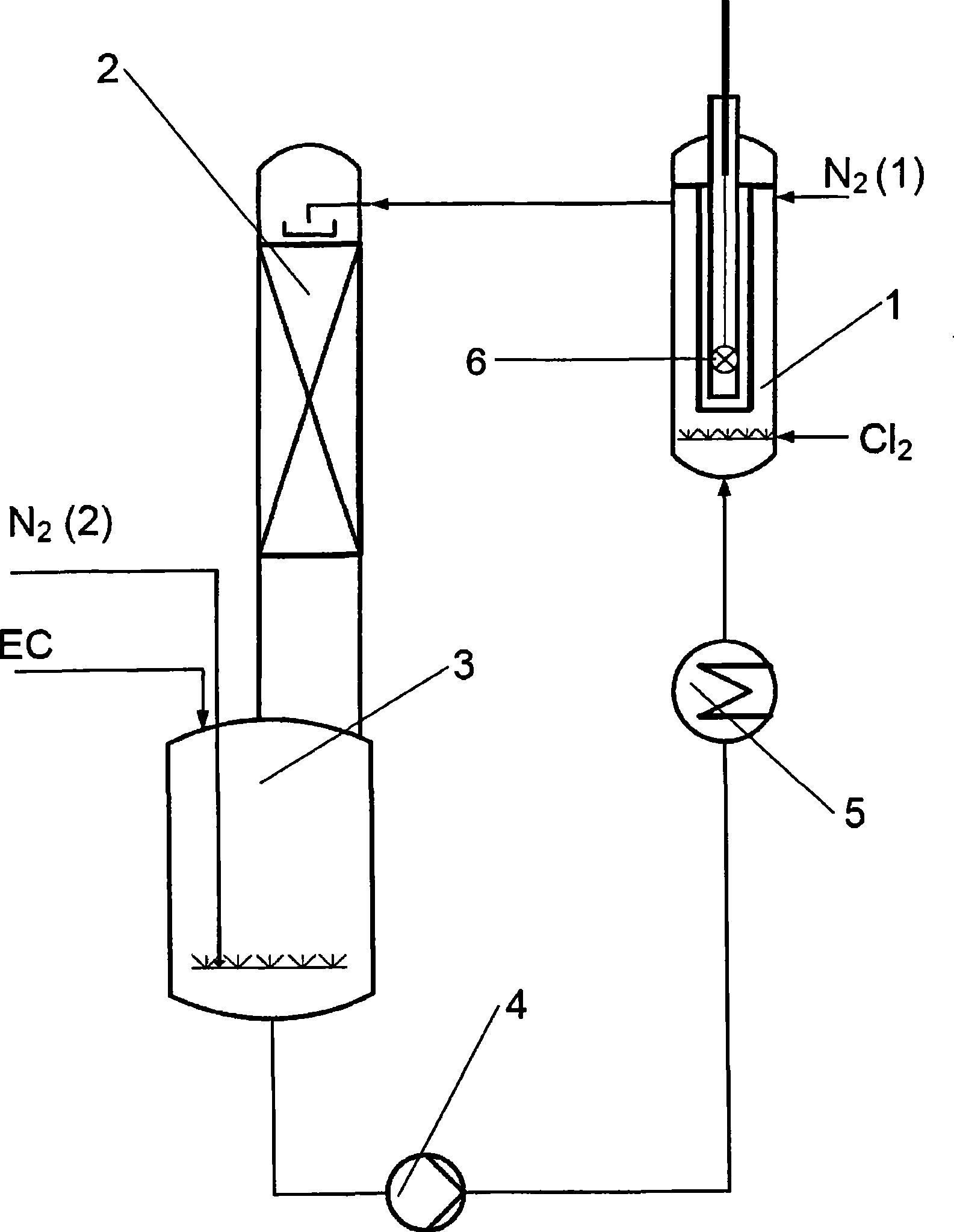

[0012] Step (a) of the method of the present invention includes the reaction of ethylene carbonate and chlorine gas in a liquid phase under ultraviolet light irradiation. Step (b) involves adding a separate feed of inert gas to the liquid phase.

[0013] Preferably, steps (a) and (b) are performed sequentially, that is, step (b) is performed after step (a).

[0014] At the beginning of the reaction, molten ethylene carbonate typically constitutes the main part of the liquid phase, optionally combined with a suitable solvent as a diluent. Although the liquid phase of the method can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com