Polymers dispersed liquid crystal light valve and method for making same

A technology of dispersing liquid crystals and manufacturing methods, which is applied in optics, optomechanical equipment, nonlinear optics, etc., can solve the problems of thick PDLC light valves, difficulty in manufacturing, poor glass elasticity, etc., to ensure uniformity and consistency , the effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the embodiment of the present invention, a flexible substrate is used to make a PDLC light valve. Various flexible substrate materials are different in terms of bending ability, surface finish, surface treatment technology, water isolation and oxygen permeability, etc. By selecting different flexible substrate materials, flexible substrates with different properties can be manufactured. In the embodiment of the present invention, a flexible substrate made of a polymer flexible material, such as a polyester film (PET) material, is preferred.

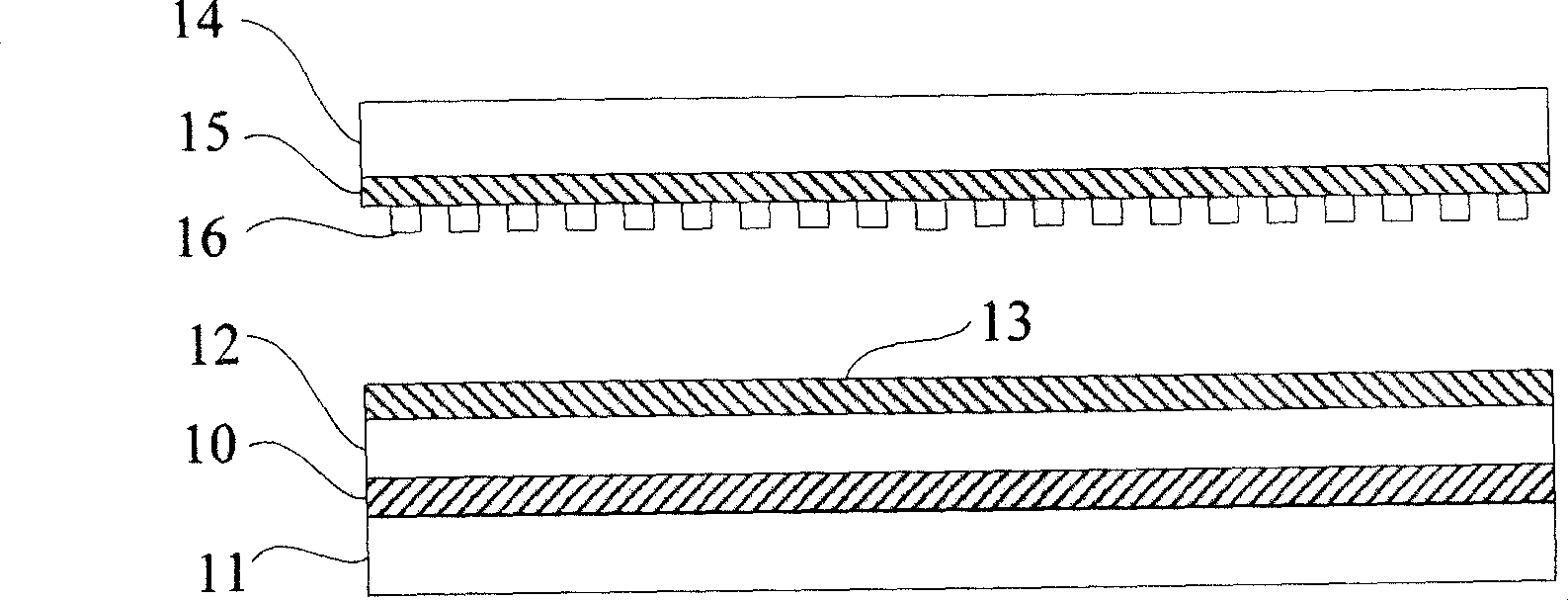

[0034] Such as figure 1 As shown, the flexible PDLC light valve of the embodiment of the present invention includes a lower substrate 11 and an upper substrate 14 made of flexible materials, and a lower ITO (Indium Tin Oxides, nanometer indium tin metal oxide) electrode 10 plated on the lower substrate 11 , the insulating layer 12 solidified on the surface of the lower ITO electrode 10 and the PDLC material layer 13 coated on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com