Low melting point alloy thermal interface material

A technology of thermal interface material and heat dissipation module, which is applied in cooling/ventilation/heating transformation, electrical components, circuits, etc., and can solve problems such as leakage of hot melt droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The advantages and spirit of the present invention, as well as more detailed implementations, can be further understood through the following implementations and drawings.

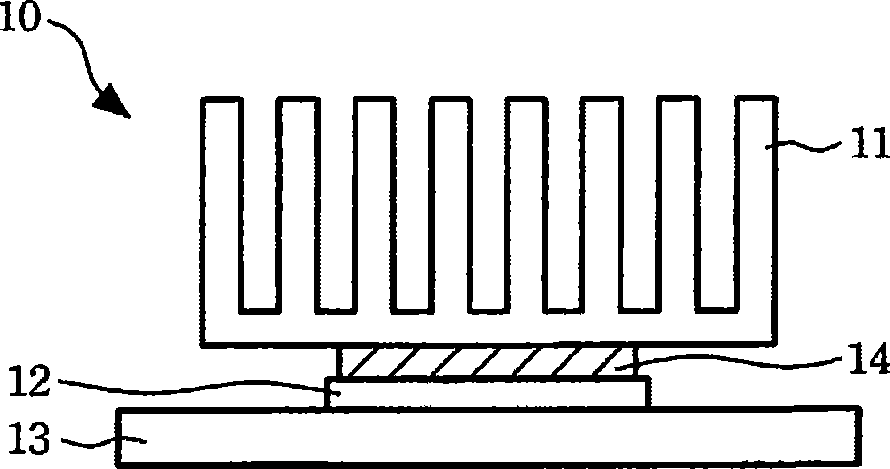

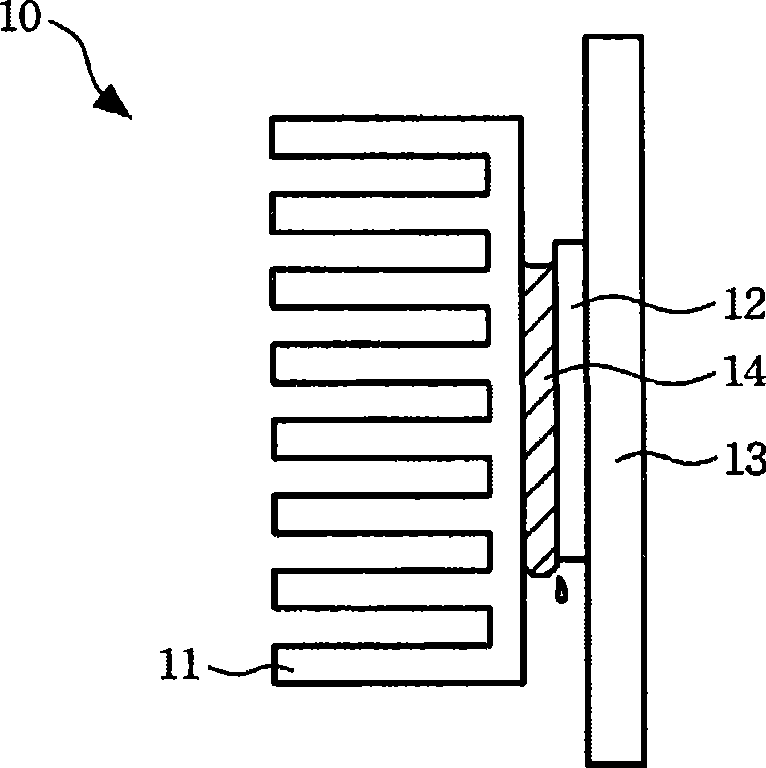

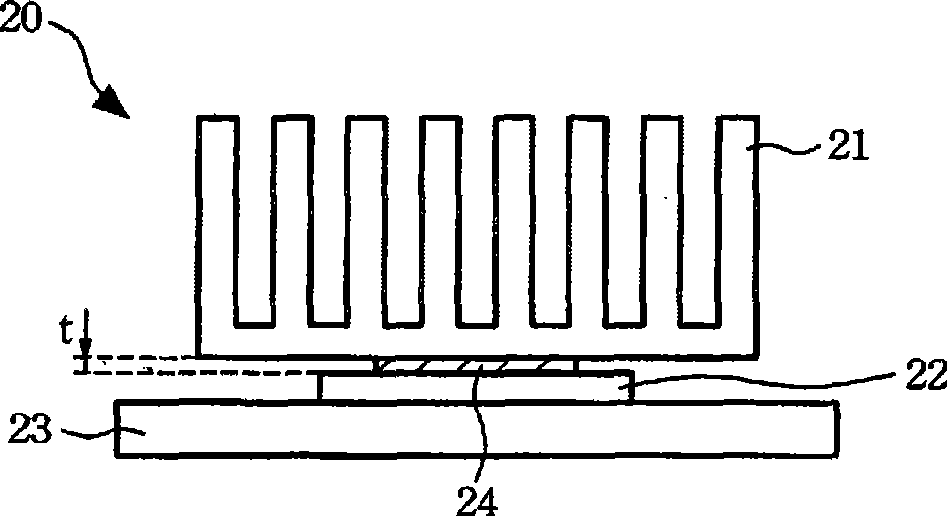

[0036] Please refer to Figure 2A , which is a schematic diagram of an embodiment of the heat dissipation module of the present invention. The heat dissipation module 20 of the present invention can quickly transfer the heat generated by an electronic component 22 to the external environment. The heat dissipation module 20 includes a heat sink 21 and a low melting point alloy foil 24 . As shown in the figure, the heat sink 21 is disposed above the electronic component 22 , and the low melting point alloy foil 24 is disposed between the electronic component 22 and the heat sink 21 , and serves as a thermal interface material between the electronic component 22 and the heat sink 21 . In addition, the electronic components 22 are disposed on a circuit board 23 and are electrically connected to each ot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com