Efficient rinsing desorption technique of sand filteration tank

A sand filter tank, desorption technology, applied in the direction of filtration separation, gravity filter, loose filter material filter, etc., to achieve the effect of protecting the environment, improving the effect, and huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

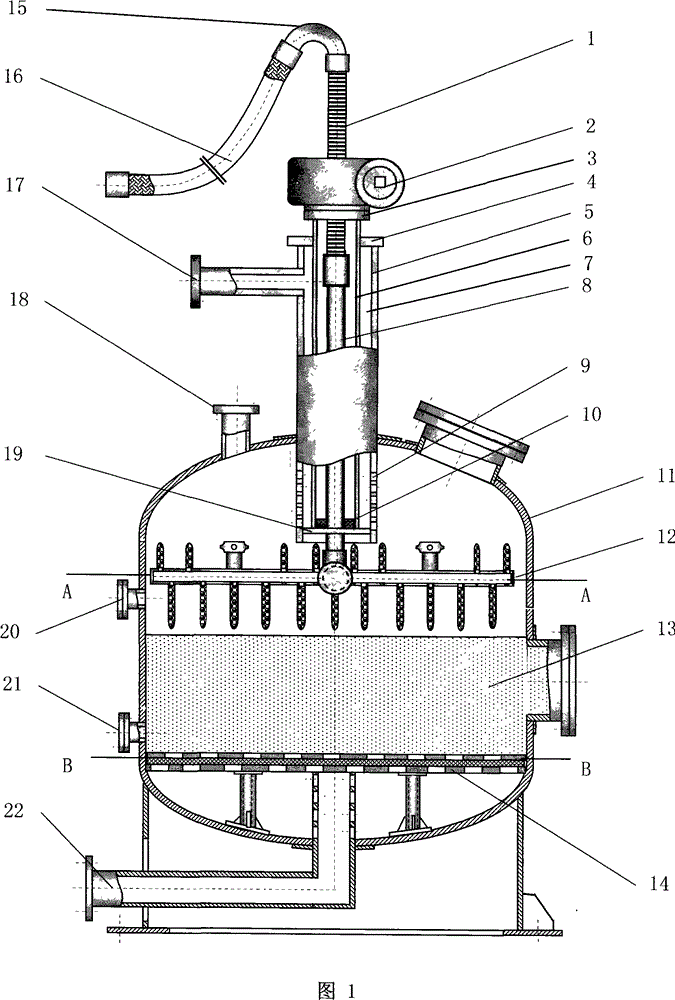

[0013] figure 1 In , the pre-filter water inlet and the rinse water inlet are separated by a concentric sleeve. Concentric tubes extend vertically into the canister from the center of the tank top. There is an annular plate (4) connected and sealed between the surface layer pipe (5) and the inner layer pipe (6), and there is an annular centralizing plate (19) at the lower end of the annular space (7). The inner layer pipe (6) and the center pipe (8) ) with a gasket (10) at the lower end, the upper end of the inner tube (6) is higher than the annular plate (4) and a flange (3) is connected to the elevator (2), the surface tube (5) is connected to the filter tank (11) Connect, the part that the lower end of the concentric sleeve pipe stretches into the filter tank is the loose water tailpipe (9). The filtration process is: the pre-filtered water enters the filter tank (11) from the water inlet (17) through the annular space (7) and the diffuser tailpipe (9), and passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com