Clean production process of treating high concentration to-be-incinerated organic waste liquor by reproducible targeted adsorption

An organic waste liquid and adsorption treatment technology, which is applied in the direction of adsorption water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of waste of resources, complicated process, high cost of environmental protection treatment, etc., and achieve saving Treatment cost, improve treatment efficiency, solve the effect of desorption unclean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

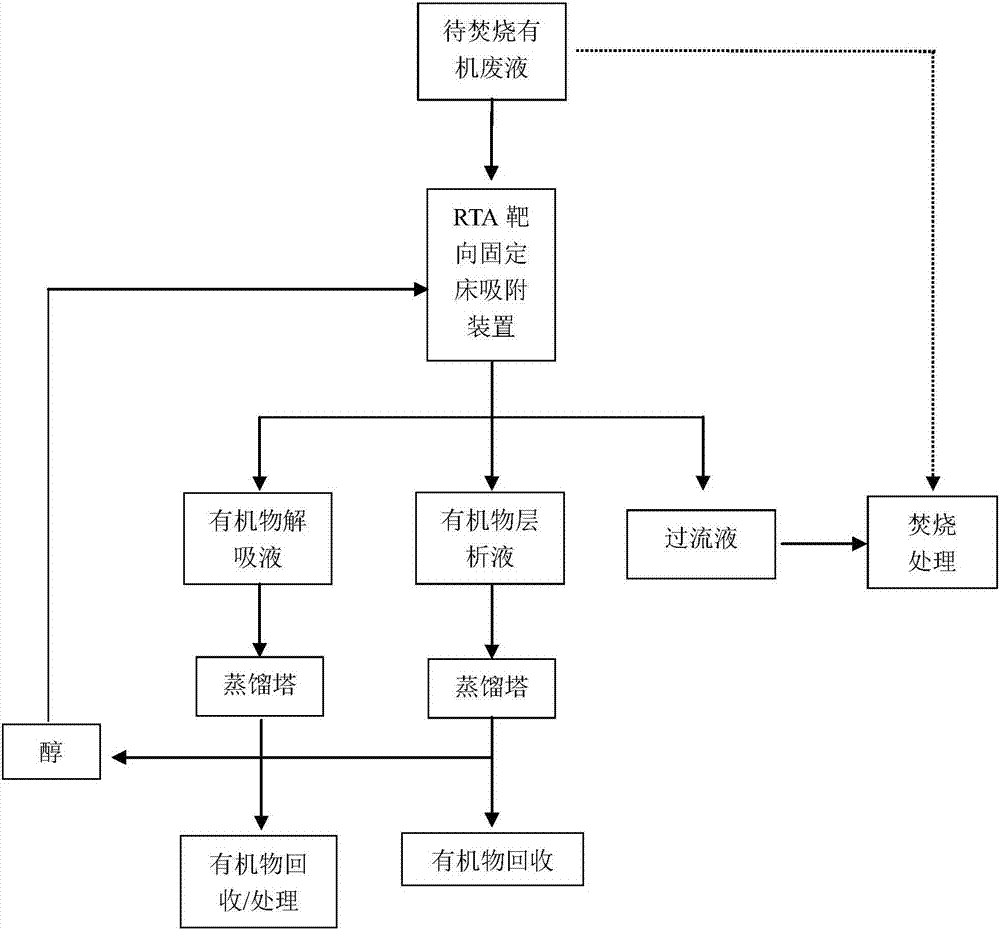

[0028] In this example, a clean production process for treating high-concentration organic waste liquid to be incinerated by renewable targeted adsorption is applied to a clean production process for treating high-concentration caprolactam organic waste liquid to be incinerated, including the following steps:

[0029] (1) The toluene method is used to prepare the organic wastewater generated in the production process of caprolactam, and the high-concentration organic waste to be incinerated containing caprolactam, toluene, acetic acid and other impurities (a small amount of benzoic acid, hexahydrobenzoic acid, and nitroterephthalic acid) is The waste liquid is sent to a regenerative targeted adsorption fixed bed device for targeted adsorption;

[0030] (2) Send the overflow liquid containing high concentration of organic impurities after being adsorbed by the regenerative targeted adsorption fixed bed device to the waste liquid incineration device for incineration;

[0031] (3...

Embodiment 2

[0038] The steps of a clean production process for treating high-concentration organic waste liquid to be incinerated by renewable targeted adsorption described in this example are the same as those in Example 1, with the difference that: the sulfuric acid solution with a mass fraction of 1.4% is used to The regenerable targeted adsorption device undergoes forced regeneration after ethanol regeneration.

Embodiment 3

[0040] In this example, a clean production process for treating high-concentration organic waste liquid to be incinerated by renewable targeted adsorption is applied to the clean production of high-concentration acrylonitrile organic waste liquid to be incinerated, including the following steps:

[0041] (1) Adopt the propylene ammoxidation method to prepare the organic waste water produced in the acrylonitrile production process, carry out the membrane separation treatment through the reverse osmosis membrane separation device, will flow down containing acrylonitrile, acetonitrile and other organic impurities (being a small amount of acrolein and acrylic acid) High-concentration organic waste liquid to be incinerated is sent to a regenerative targeted adsorption fixed bed device for targeted adsorption;

[0042] (2) Send the overflow liquid containing high concentration of organic impurities after being adsorbed by the regenerative targeted adsorption fixed bed device to the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com