Ironmaking casting system

An iron-smelting blast furnace and processing system technology, applied in the fields of metal iron-smelting and casting, can solve the problems of occupying land, wasting secondary melting energy costs, expanding pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

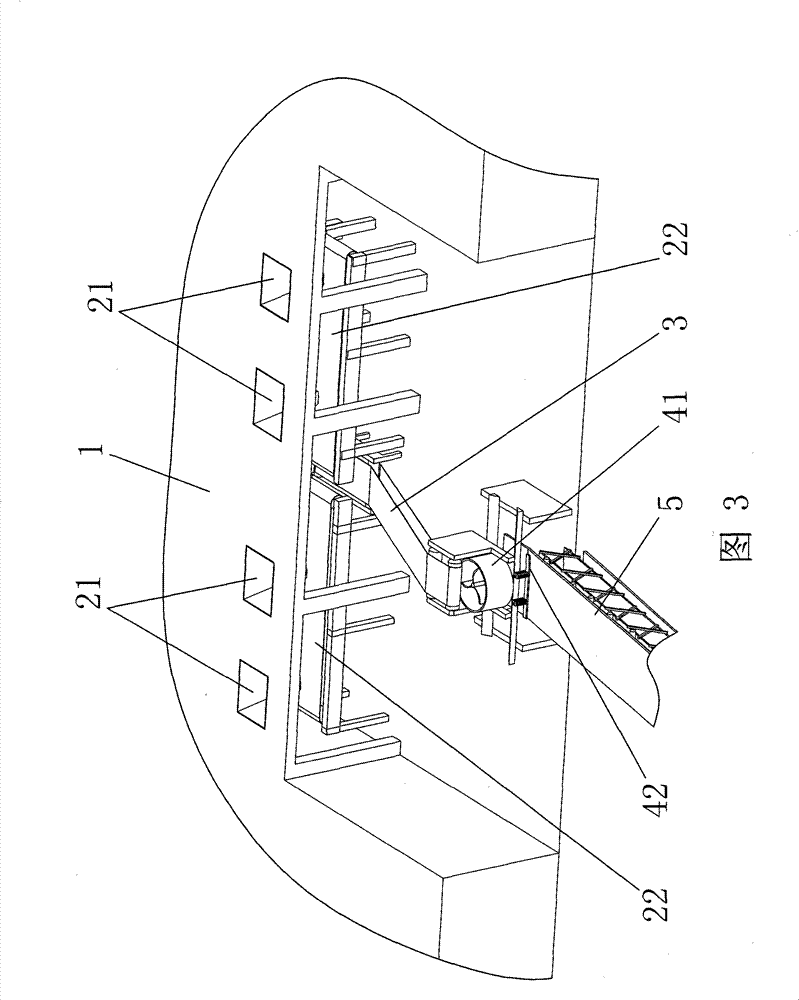

[0022] An ironmaking casting system as shown in Fig. 1 and Fig. 2 includes ore coke proportioning device 2, ore coke mixing device 4, conveying device, ironmaking blast furnace 9, fuel gas treatment system 11, slag water treatment system 8 and The air input system 10 also includes an oxygen supply device 14, an aerosol mixer I for mixing oxygen and additives, an aerosol mixer II for mixing oxygen and additives, heating the high-temperature molten iron before casting, elements A magnetic string oscillation device 12 for homogenization treatment, a molten iron transfer car 13 and a casting system 15, the ore coke proportioning device 2 is connected to the ore coke mixing device 4 through a conveying device, and the ore coke mixing device 4 is connected to the ironmaking blast furnace through a conveying device 9 connection, the fuel gas outlet of the ironmaking blast furnace 9 is connected to the fuel gas treatment system 11, the slag outlet of the ironmaking blast furnace 9 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com