Chemical vapor deposited silicon carbide articles

A technology of chemical vapor deposition and silicon carbide, which is applied in the direction of gaseous chemical plating, chemical instruments and methods, electrical components, etc., can solve many problems such as time and cost, and achieve the effect of reducing particle pollution, reducing difficulty, and reducing TP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Example 1 (comparative)

[0069] Three types of joints were prepared to test their strength using the standard test method used to test joint strength. There are two types of joints including round CVD-SiC end plates and corresponding rectangular CVD-SiC rods for inserting into the side interfaces of each end plate. The third type of joint is composed of a circular sintered silicon carbide end plate and a corresponding rectangular sintered silicon carbide rod body for inserting into the side interface of the end plate. It is made by the known CVD-SiC method and obtained CVD-SiC end plates and rods from the Advanced Materials Department of Rohm and Haas Company (Woburn, Massachusetts, USA). By a known sintering method, silicon is immersed in sintered silicon carbide to make the sintered silicon carbide end plate and rod body.

[0070] The CVD-SiC rod is inserted into the interface of the CVD-SiC end plate to form a known male-female joint to form the first type of joint. ...

Embodiment 2

[0082] Example 2 (comparative)

[0083] Three types of wafer boats are prepared by CVD-SiC to compare their TP, and they are distinguished by the type of joints connecting the components. In a chemical vapor deposition furnace tube, silicon carbide is deposited on a graphite mandrel of appropriate shape and size to prepare the CVD-SiC component. The reaction components and parameters used are disclosed in Table 2.

[0084] Table 2

[0085] Process parameters

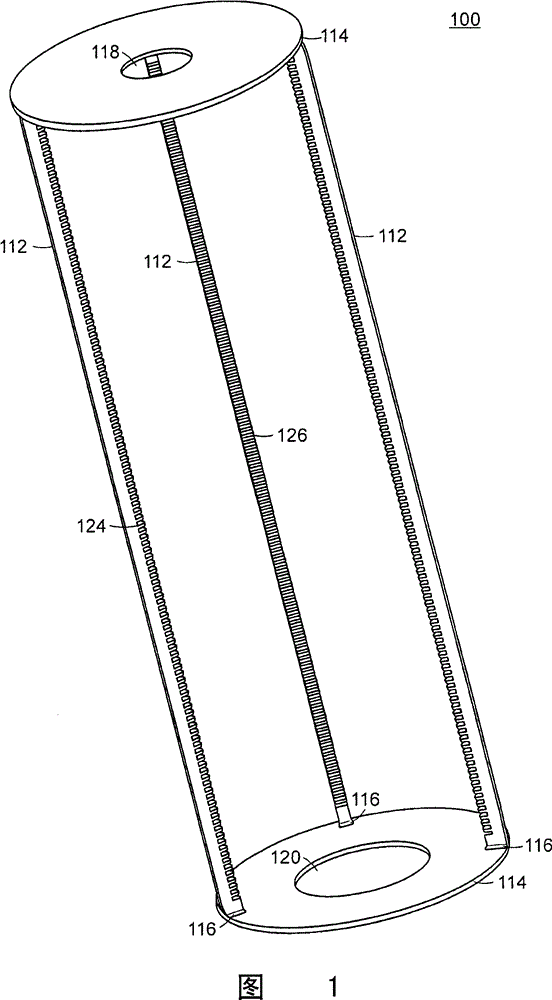

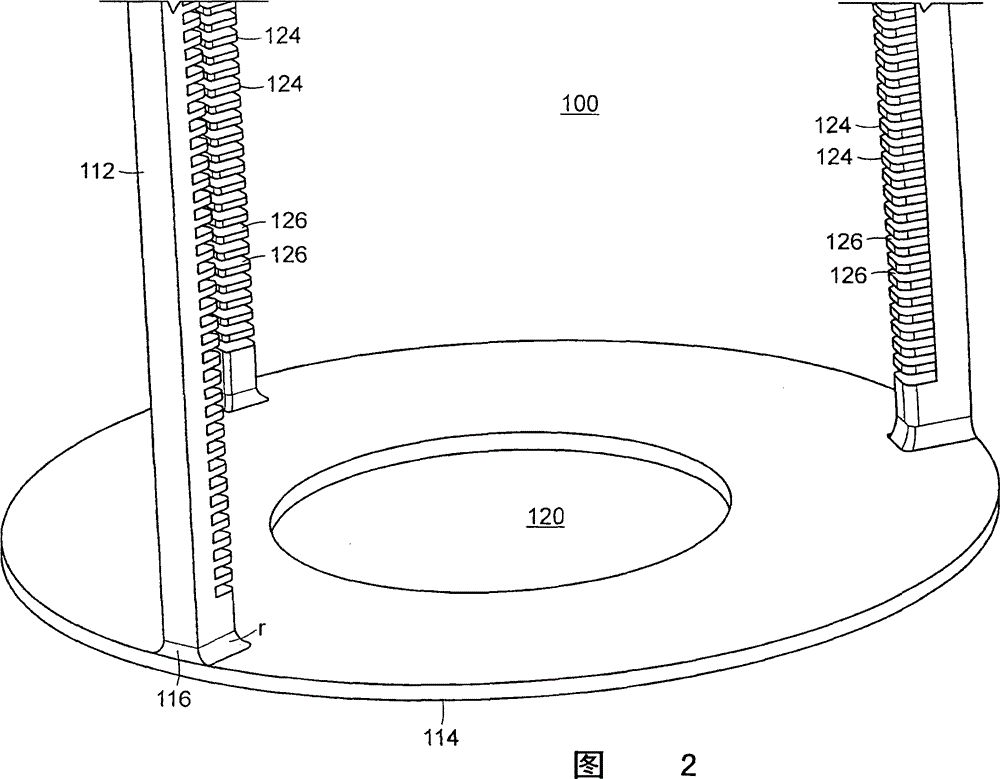

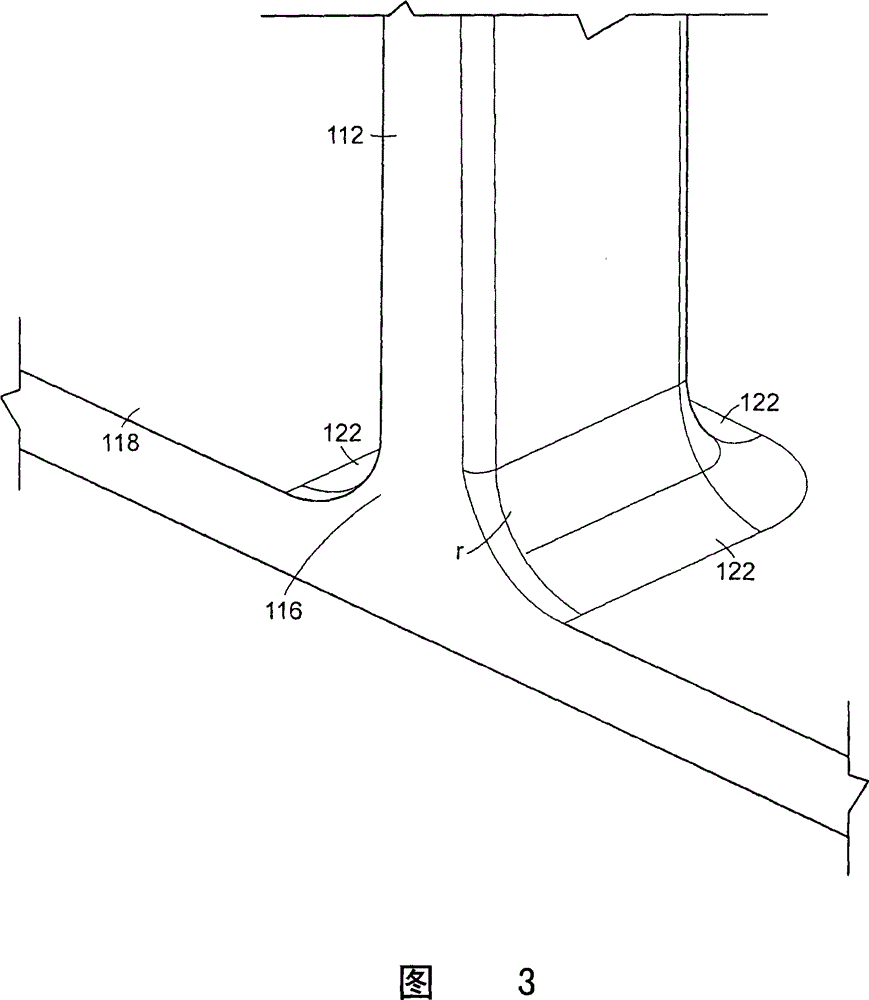

[0086] After the parts are formed on the mandrel, they are removed and machined with 220 grit diamond tools to remove any unwanted rough surfaces formed during deposition and shape the parts. Then, the components are assembled to form 3 wafer boats each with different types of joint combinations. Each wafer boat includes 3 rectangular rods connected to end plates at their opposite ends. Assemble all the wafer boats in a known jig so that their parts are properly aligned with the desired dimensional tolerances.

[0087]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com