A kind of advanced treatment method of natural rubber wastewater

A natural rubber, advanced treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effect of improving treatment efficiency, good operation stability, and high volumetric load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

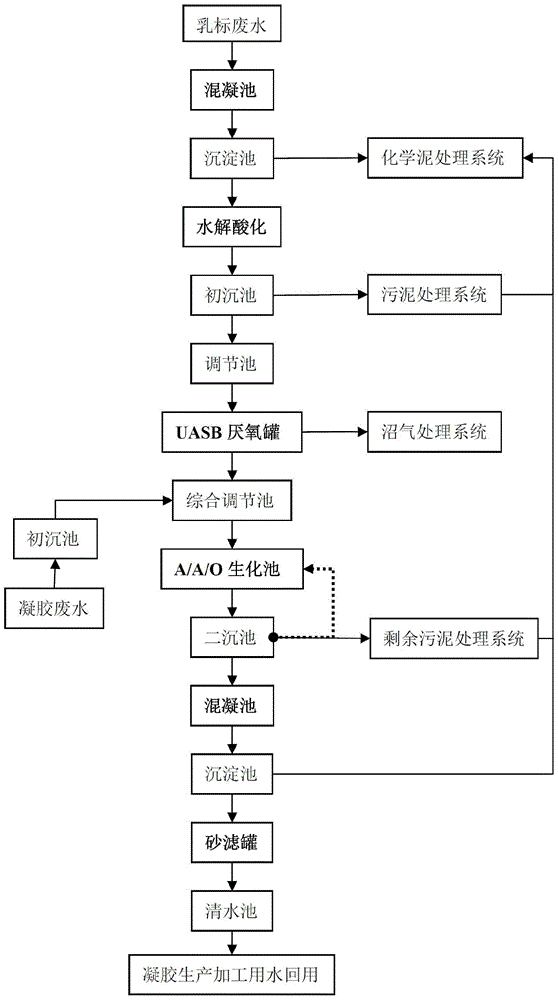

[0027] like figure 1 As shown, the latex processing wastewater of Hainan Sinochem Rubber No. 2 Plant was taken as the research object for advanced treatment:

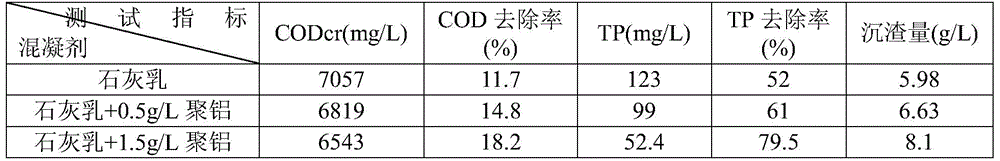

[0028] (1) Lime milk coagulation treatment of latex processing wastewater: the latex processing wastewater of Hainan Sinochem Rubber No. 2 Plant enters the coagulation treatment unit, and a coagulant is added to the treatment unit. The coagulant is lime milk or lime milk and polyaluminum , stirring at 150r / min for 30-60s quickly, then stirring at 75r / min for 15-20min at a slow speed, free sedimentation for 30-50min, and taking CODcr, TP, and sediment amount as test indicators for the treated wastewater to screen the coagulant type and Consumption amount (referring to Table 1), wherein, the addition amount of milk of lime is to make the pH value of wastewater to be treated reach 7-8, and milk of lime is the emulsion that mass volume ratio is 10%. The water quality in the latex processing wastewater of Hainan Sinochem Ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| inhomogeneity coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com