Leather belt grooving apparatus and method

A technology of belt and strip groove, which is applied in belt/strip production, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather/fur mechanical treatment, etc., which can solve the problem of high processing cost and high manufacturing cost , affecting the quality of the belt and other issues, to achieve the effect of convenient production and improved dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

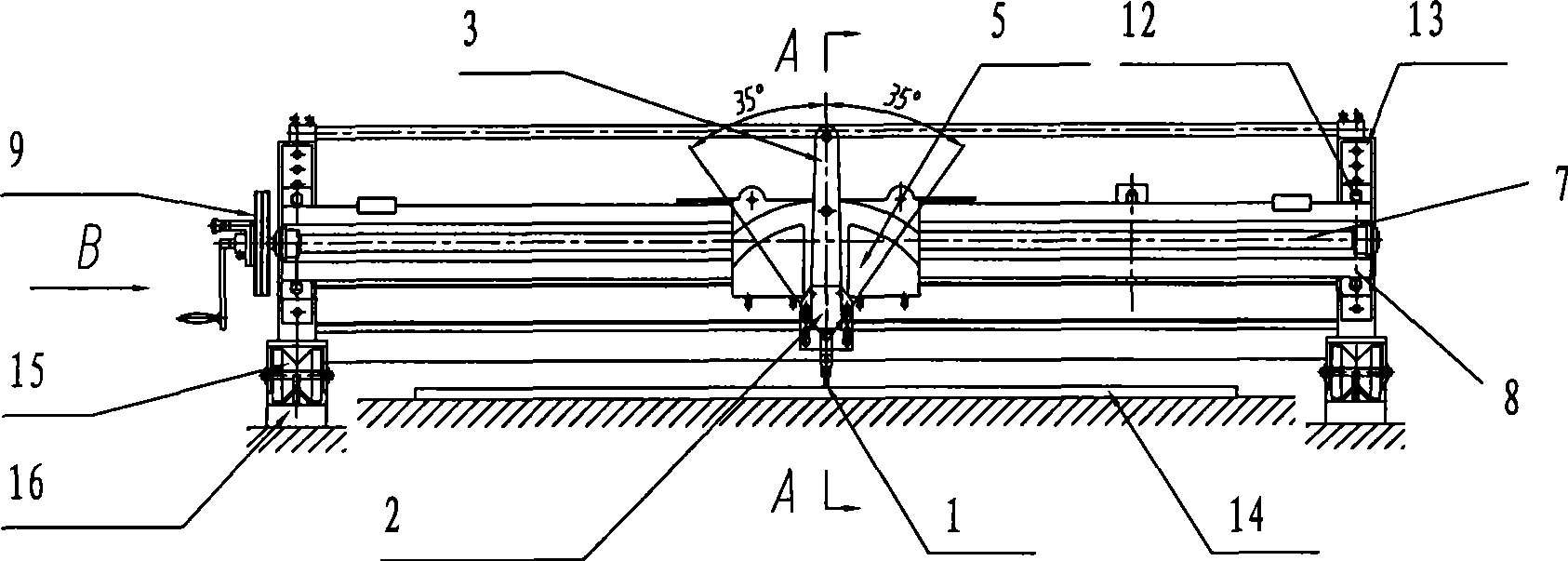

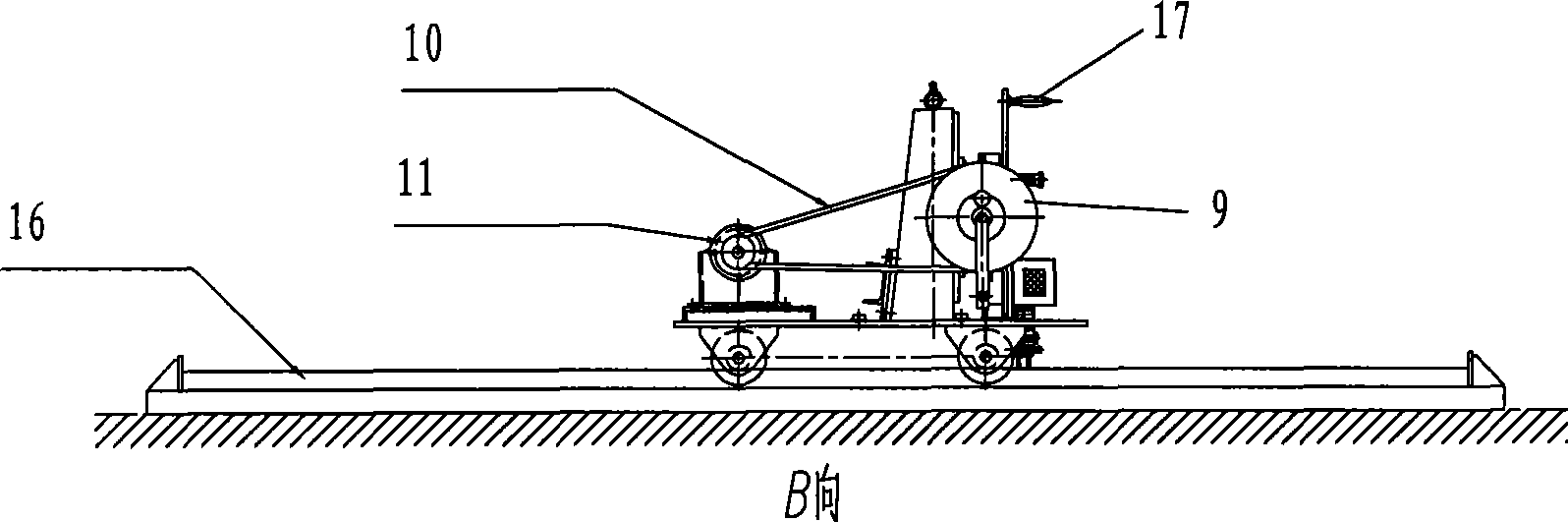

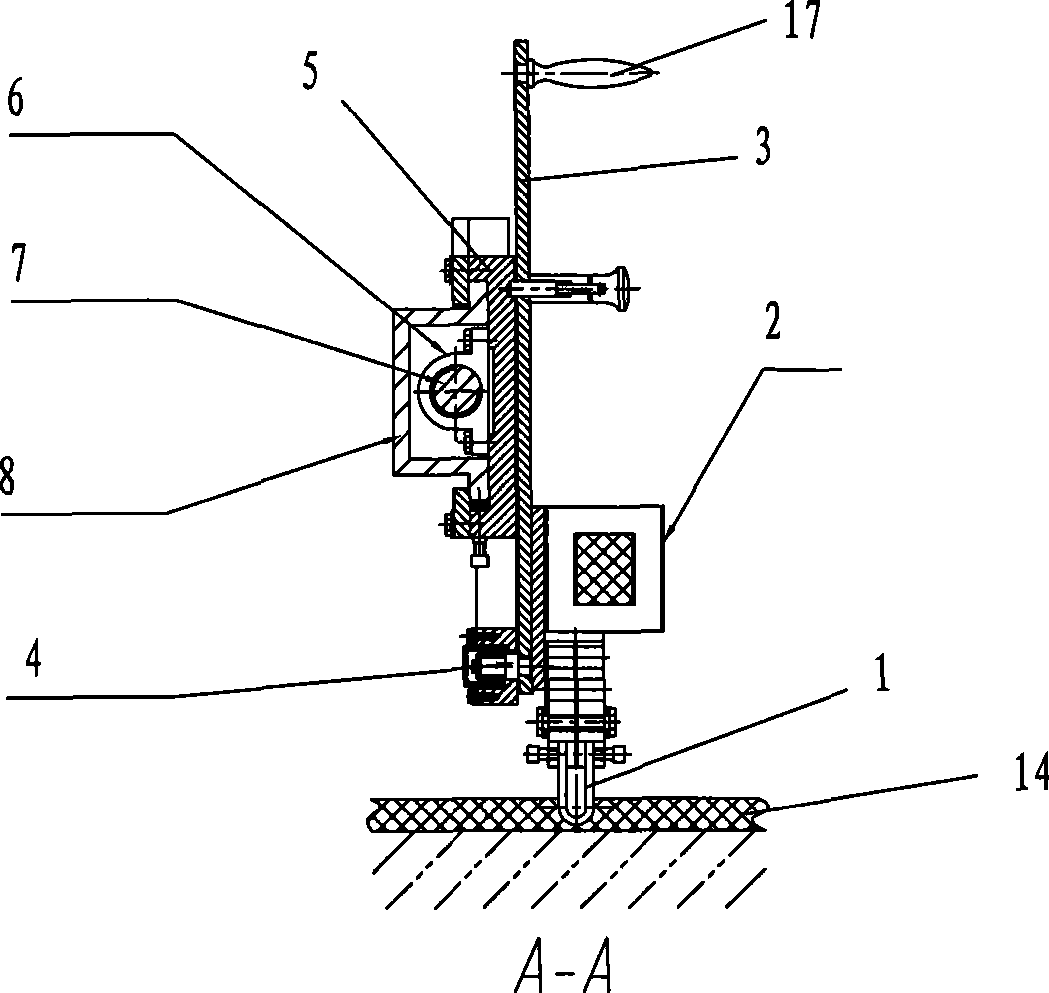

[0041] The specific implementation of the belt slotting device and method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0042] The structure of the belt notching device of the present invention includes the following components.

[0043] see Figure 1-3 as shown, figure 1 It is a structural diagram of the belt slotting device of the present invention; figure 2 yes figure 1 B direction view; image 3 yes figure 1 The A-direction cross-sectional view of the belt slotting device in slotting.

[0044] The slotted cutter 1 is made of conductive metal, and has the same shape as the slot to be opened by the slotted belt, generally U-shaped.

[0045] The cutter 1 is installed on the output end of the heating transformer 2, which is equivalent to a low-resistance load of the heating transformer 2. The cutter 1 is heated by the heating transformer 2 to perform thermal grooving operation on the belt.

[0046] Described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com