Parameter-embedded analog transducer calibration method

A technology that simulates sensors and pressure sensors. It is used in earth-moving drilling, measurement, wellbore/well components, etc. It can solve the problems of zero-point drift, inability to continue drilling operations, and no pressure sensors, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

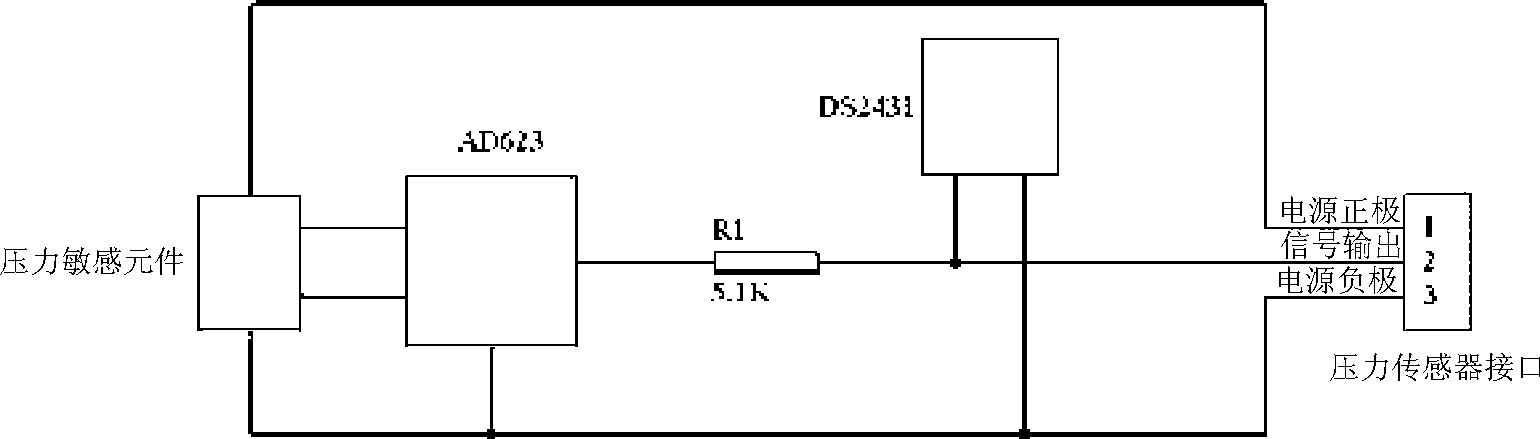

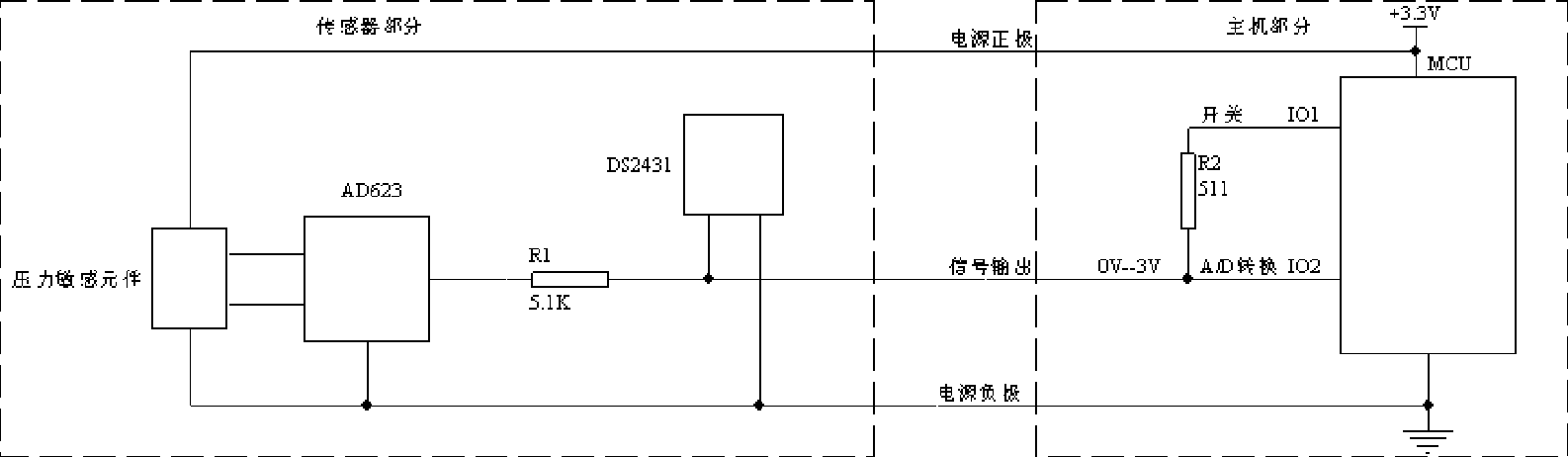

[0022] First, refer to figure 1 , the principle structure diagram of the existing pressure sensor communication method, the function of connecting a resistor R1 in series at the output end of the instrument amplifier U1 is that the analog signal will not affect the digital signal communication. Then the single bus chip U2 is directly connected to the signal line.

[0023] refer to figure 2 , the process steps of a method for calibrating an analog sensor with built-in parameters of the present invention are as follows:

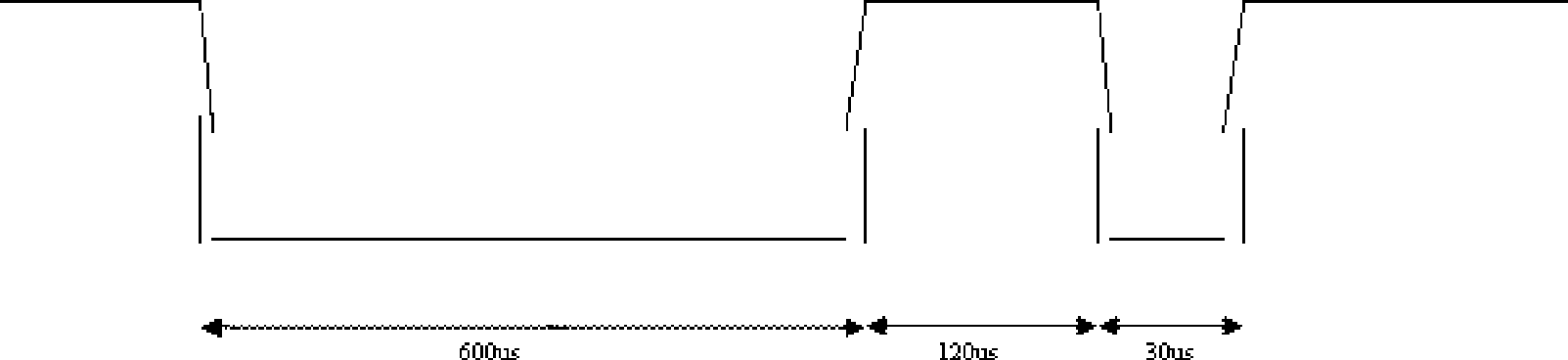

[0024] Step 1: When the host starts to communicate with the EEPROM chip, the chip must be woken up first. figure 2 The host first sends a low level with the IO2 port, the duration is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com