Thermoplastic resin foam

A thermoplastic resin and foam technology, used in flat products, household appliances, other household appliances, etc., can solve the problem of delaying the deterioration rate of resin products, and achieve the effect of enhancing UV resistance, inhibiting discoloration, and reducing the amount of resin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Polyethylene terephthalate (GRADE: C-0312, manufactured by UNITIKA Co., Ltd.) was molded into a sheet having a thickness of 0.6 mm×a width of 300 mm×a length of 60 m. Make this resin sheet and 160 μm thick * 290mm wide * 60m long, basis weight 55g / m 2 Separators of olefin-based nonwoven fabric (GRADE: FT300, manufactured by Nippon Belloyer Co., Ltd.) were stacked and rolled into a roll so that there was no part where the surfaces of the resin sheets were in contact with each other. Then, this roll was placed in a pressure vessel, and the pressure was increased to 6 MPa with carbon dioxide gas, so that the carbon dioxide gas was permeated into the resin sheet. The permeation time of carbon dioxide gas into the resin sheet was 72 hours. Then, the reel was taken out from the pressure vessel, the spacer was removed, and only the resin sheet was continuously supplied to a hot-air circulation foaming furnace set at 220° C., and foaming was performed at a foaming time of 1 mi...

Embodiment 2

[0061] To polyethylene terephthalate (GRADE: C-0312, manufactured by UNITIKA Co., Ltd.), a masterbatch (NANOMAXEZ153, manufactured by Showa Denko) containing an inorganic oxide filler (zinc oxide) having ultraviolet shielding properties is added, The filler content was adjusted to 0.5 parts by mass, kneaded, and then formed into a thin sheet with a thickness of 0.6 mm x a width of 300 mm x a length of 60 m, and the sheet was foamed under the same conditions as in Example 1.

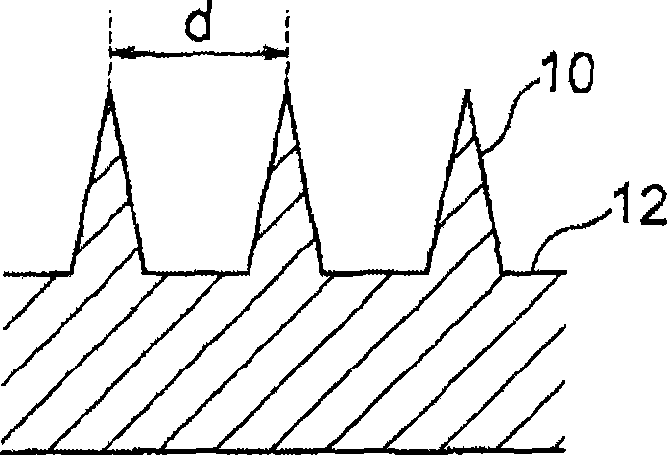

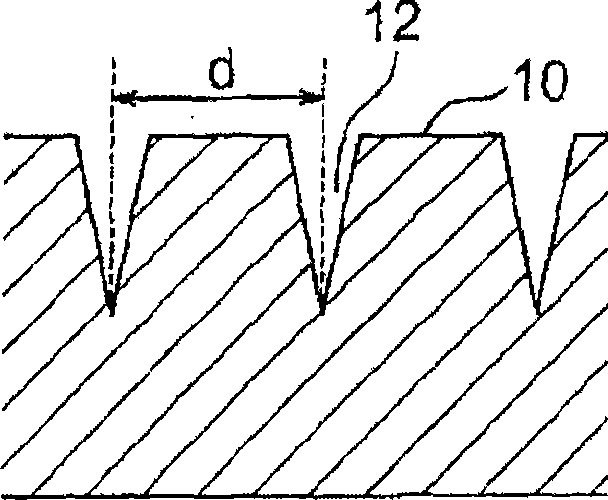

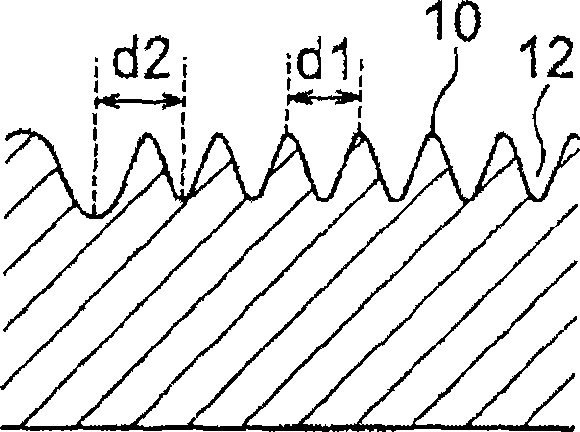

[0062] The obtained foam foamed uniformly and had an average cell diameter of 7 μm, which was very fine. The thickness of the foam was 1.0 mm, and the average reflectance of the foam showed a high value of 97.8%. In the same manner as in Example 1, only 0.2 mm of the surface layer of the foam was removed. The unevenness of the surface of the foam was confirmed and d was measured, and d was 8 μm. In addition, the ultraviolet resistance of the foam was evaluated, and the result of ΔE * It is 10.4, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com