Trackless type self-protecting complete position automatic soldering device and welding process thereof

An automatic welding and self-protection technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of many auxiliary welding materials, cumbersome equipment such as root welding machines, and high welding joint assembly accuracy, so as to ensure the welding joints. The quality and line energy are easy to control, and the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

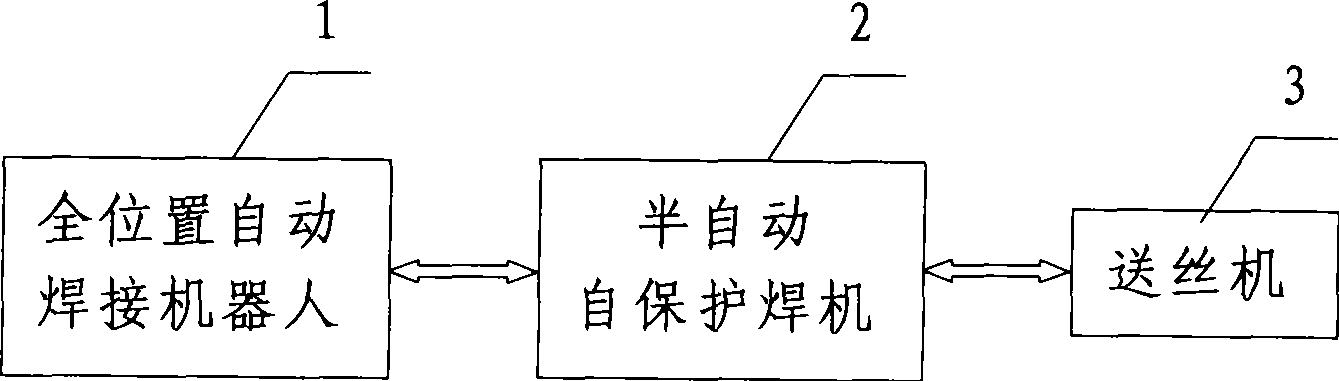

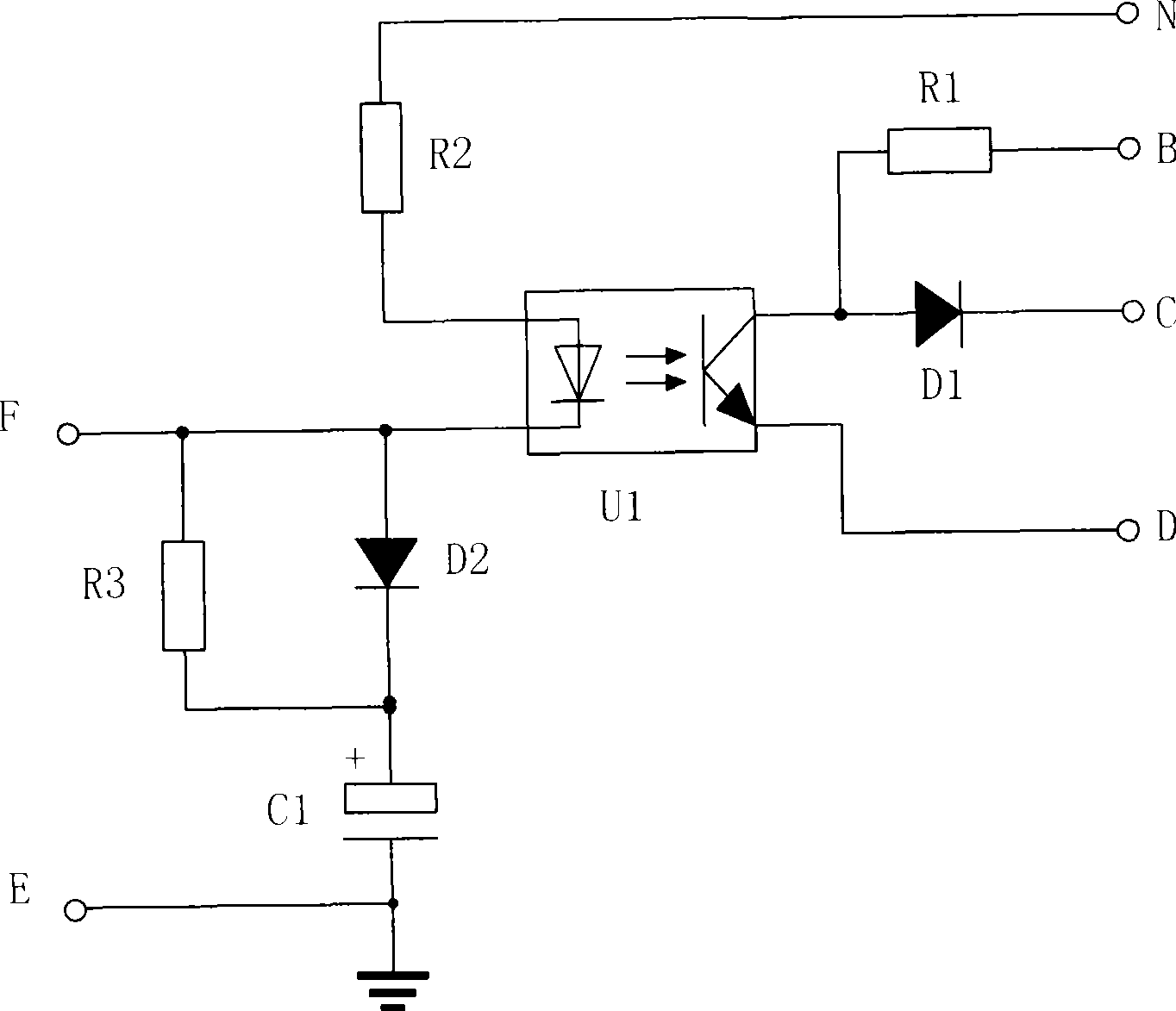

[0036] Such as figure 1 As shown, the trackless self-protection all-position automatic welding device used in the present invention includes an all-position automatic welding robot 1, a semi-automatic self-protection welding machine 2 driven by the all-position automatic welding robot 1 for welding, and a semi-automatic self-protection welding machine 2 connected The wire feeder 3. Wherein, the all-position automatic welding robot 1 includes a control system, a photoelectric tracking device connected to the control system and its feedback device, a walking trolley controlled by the control system, and a drive for driving the walking trolley. mechanism and the magnetic attraction device that adheres and fixes the walking trolley on the channel it moves, and the welding torch of the semi-automatic self-shielded welding machine 2 is fixed on the walking trolley of the all-position automatic welding robot 1 . The wire feeder 3 is internally provided with a time-delay arc breaking...

Embodiment 2

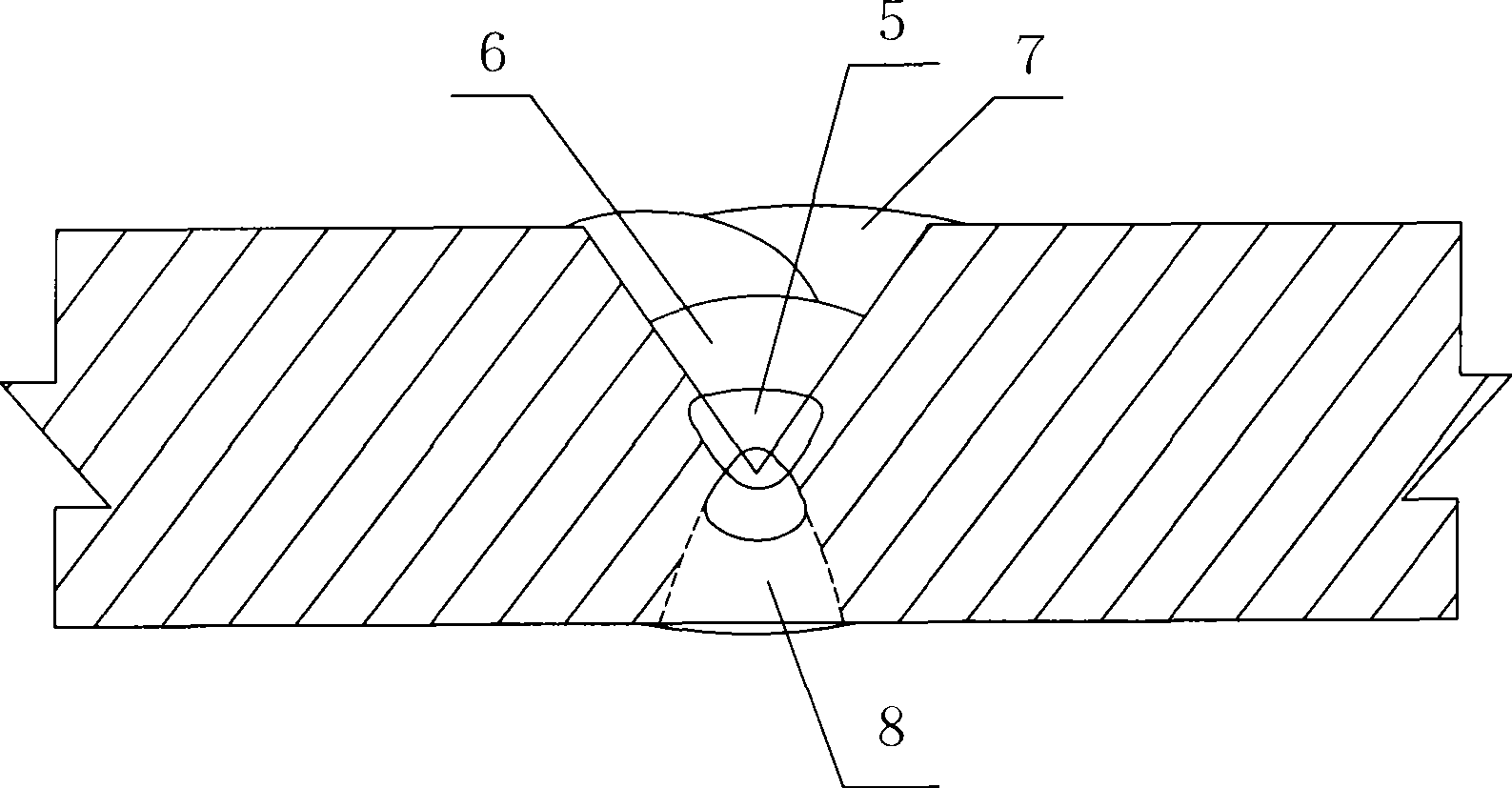

[0053] combine Figure 4 , in this embodiment, the material of the welded part 4 described in step 1 is SUMITEN610-TMC steel, and the self-shielded welding wire described in step 3 is a diameter 2.0mm self shielded welding wire JC-30 or diameter 5 / 64″mm self-shielded welding wire E71T8-K6.

[0054] First of all, according to the conventional mechanical processing technology, the groove is processed on the welded part 4. The material of the welded part 4 is SUMITEN610-TMC controlled rolling steel, and the welded part 4 is a large-diameter pipe with a pipe wall thickness of 50 mm and a pipe diameter of 4000 mm. The groove is an asymmetric double-sided V-shaped groove, the depth of the outer groove is 6mm, and the rest of the depth is all inner grooves. Groove angle is 60 0 , the blunt edge at the groove is 0-2 mm, and the gap between the grooves is 0-2 mm. Place the large-diameter pipe joint horizontally (the pipe axis is parallel to the ground), and perform all-position w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com