Preparation of polymeric ferric sulfate

A technology for polymerizing ferric sulfate and ferrous sulfate, which is applied in the fields of ferric sulfate, sustainable manufacturing/processing, chemical industry, etc., to reduce production costs, shorten reaction time, and solve time-consuming and laborious effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

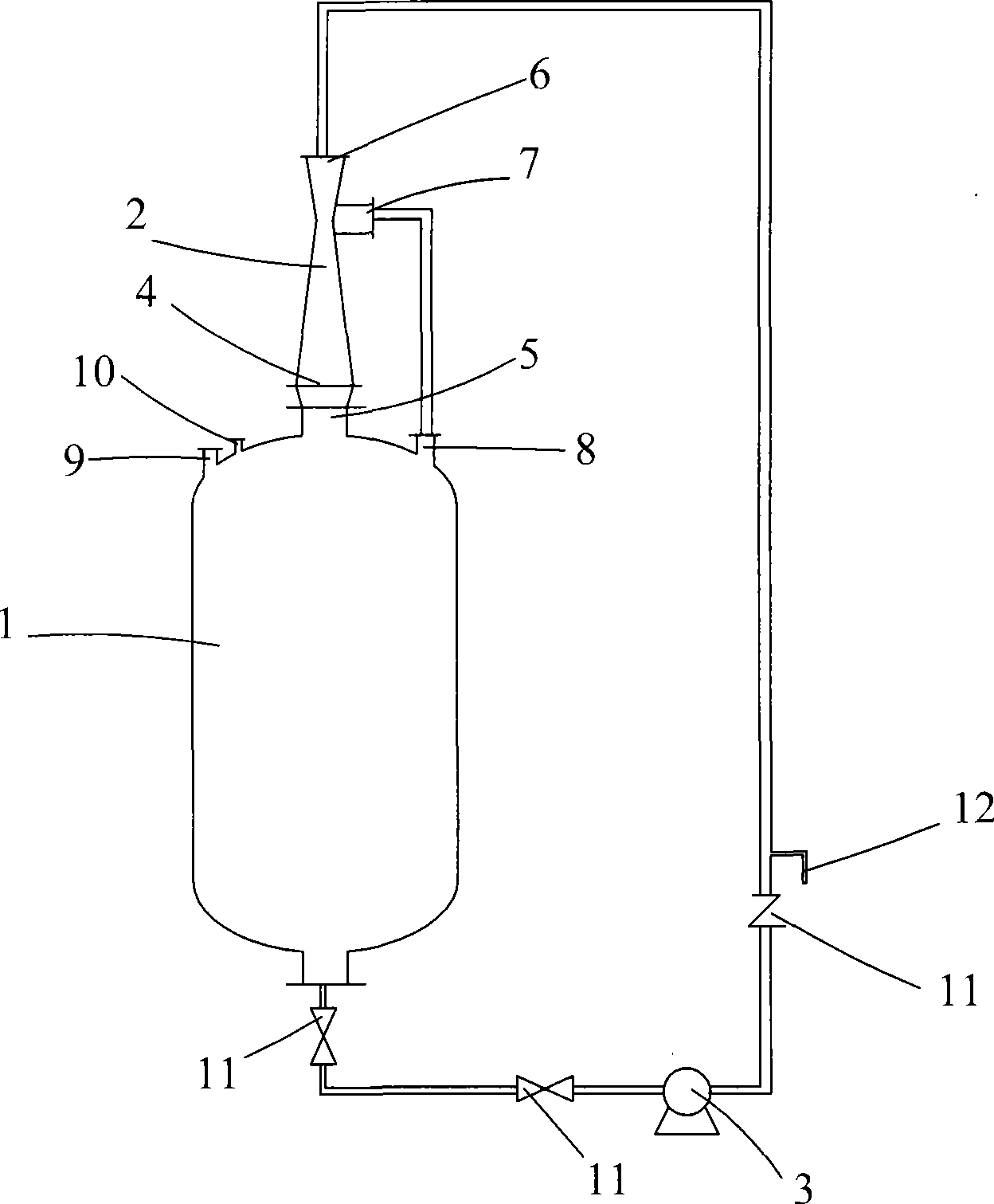

[0030] The pickling waste water containing 2.5% (w / w) iron is added to the dissolution tank, and then 50kg of concentrated sulfuric acid (98%) and 458kg of ferrous sulfate (15.6%) are added to each ton of waste liquid. When the ferrous sulfate is basically dissolved, it is transferred to the figure 1 In the shown oxidation reactor device body 1, add 4.5kg NaNO through the catalyst inlet 9 2 1680L of oxygen is introduced from the oxygen inlet 10, and then the circulation pump 3 of the oxidation reactor device is turned on. The liquid in the circulation pump passes through the injection of the pipeline injector 2 and the negative pressure to fully mix the gas and liquid. After 3 hours of polymerization reaction Polyferric sulfate (about 9% total iron content) is obtained.

Embodiment 2

[0032] Add the waste sulfuric acid pickling solution containing 7.5% (w / w) of iron (total iron content) to the acid-resistant dissolution tank, and then add 70kg of concentrated sulfuric acid (98%) and 246kg of ferrous sulfate (15.6%) to each ton of waste liquid . When the ferrous sulfate is basically dissolved, it is transferred to the figure 1 In the oxidation reactor body 1 shown in the oxidation reactor device, add 4.5kg NaNO from the catalyst inlet 9 2 1680L of oxygen is introduced from the oxygen inlet 10, and then the circulation pump 3 of the oxidation reactor device is turned on. The liquid in the circulation pump passes through the injection of the pipeline injector 2 and the negative pressure to fully mix the gas and liquid. After 3 hours of polymerization reaction Polyferric sulfate (11% total iron content) was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com