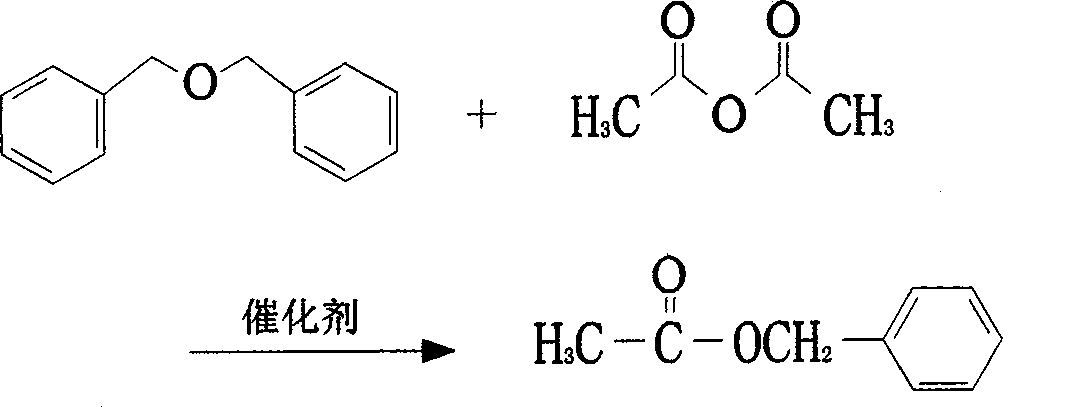

Preparation of benzyl acetate

A technology of benzyl acetate and a manufacturing method, applied in the field of preparing benzyl acetate, can solve the problems of high equipment cost, many equipment, expensive titanium metal, etc., and achieves the effects of safe transportation and storage, simple and convenient operation process, and less pollution of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 308g dibenzyl ether (industrial crude product, 91.43%, 1.420mol), 176g acetic anhydride (chemically pure, 99.0%, 1.706mol) and 7g (2.27%) solid acid catalyst p-toluenesulfonate respectively in a 1000ml three-necked flask acid, heated up to 130°C to 150°C, and reacted for 3 to 6 hours; after the reaction, about 483g of crude product was obtained, and sampling analysis showed that the content of benzyl acetate was 81.10% (GC), acetic anhydride 3.57% (GC), and dibenzyl ether 0.09% ( GC).

[0033] Put the above crude product in N 2 Distillation under reduced pressure under protection (the number of trays is about 1), the vacuum degree is -0.097~-0.098Mpa (the same below), and the material starts to discharge when the temperature of the material liquid rises to 45°C until the temperature of the material rises to about 220°C. When the material is not obvious, stop the distillation. A total of 399.3 g of distillates were received, with a benzyl acetate content of 91.24% ...

Embodiment 2

[0035] Feeding amount and reaction operation are the same as in Example 1, and the crude product obtained by the reaction is used with about 400ml of 20%Na 2 CO 3 The solution was neutralized to a pH value of 7, the brine layer was separated, and the obtained crude ester was subjected to vacuum distillation to obtain a total of 343.5 g of finished product, with a content of 99.61% (GC), a one-way yield of 79.86%, and a total yield of 83.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com