Magnesium chloride/mesoporous molecular sieve bisupported Ziegler-Natta polyethylene catalyst, preparation and use

A technology of mesoporous molecular sieve and double carrier is applied in magnesium chloride/mesoporous molecular sieve double carrier supported Ziegler-Natta polyethylene catalyst, preparation method and application field, which can solve the problem of large specific surface, high structural strength of mesoporous molecular sieve and large volume ratio. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

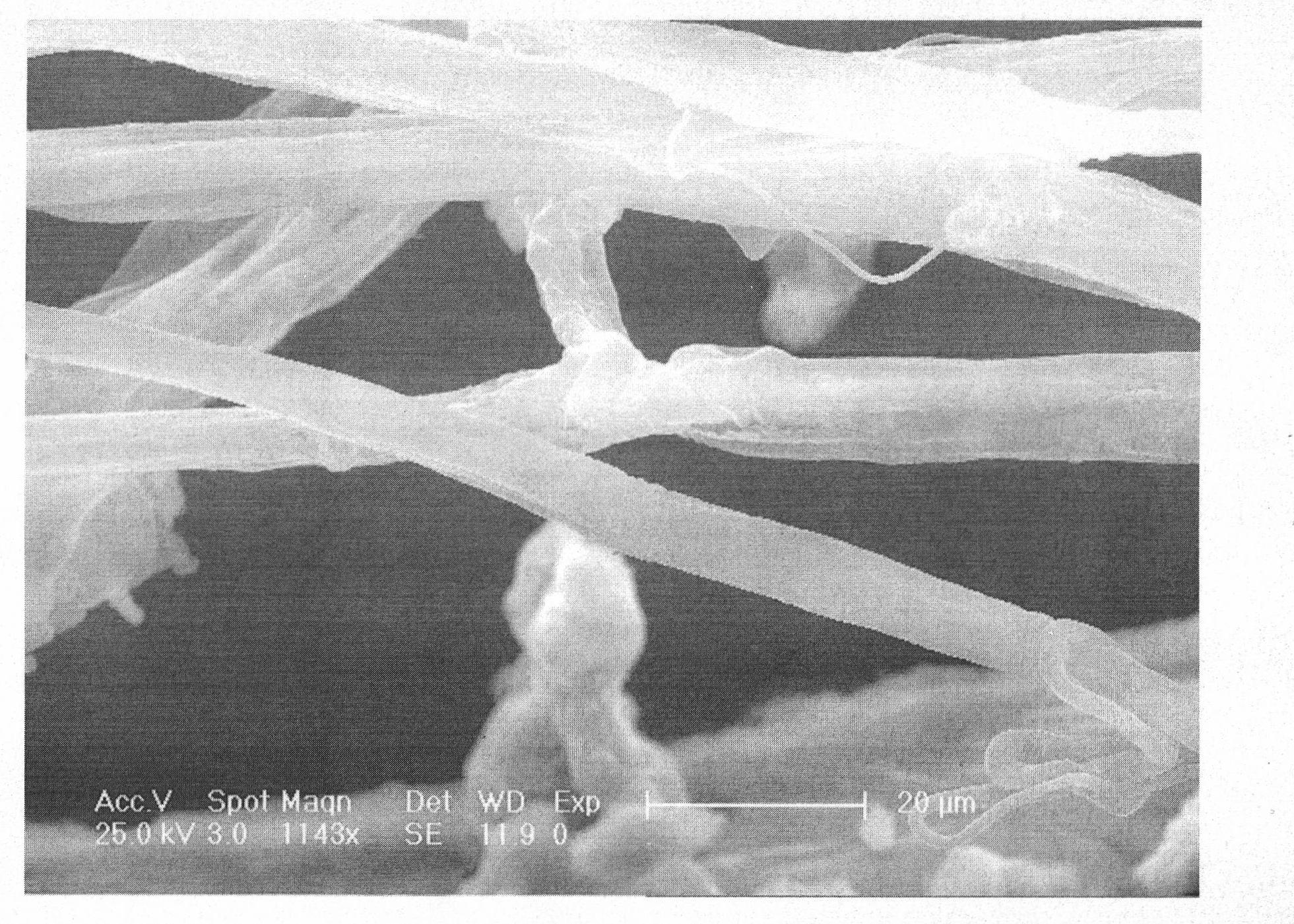

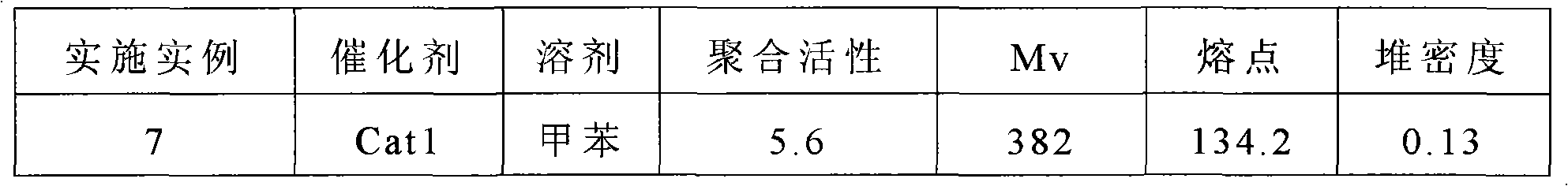

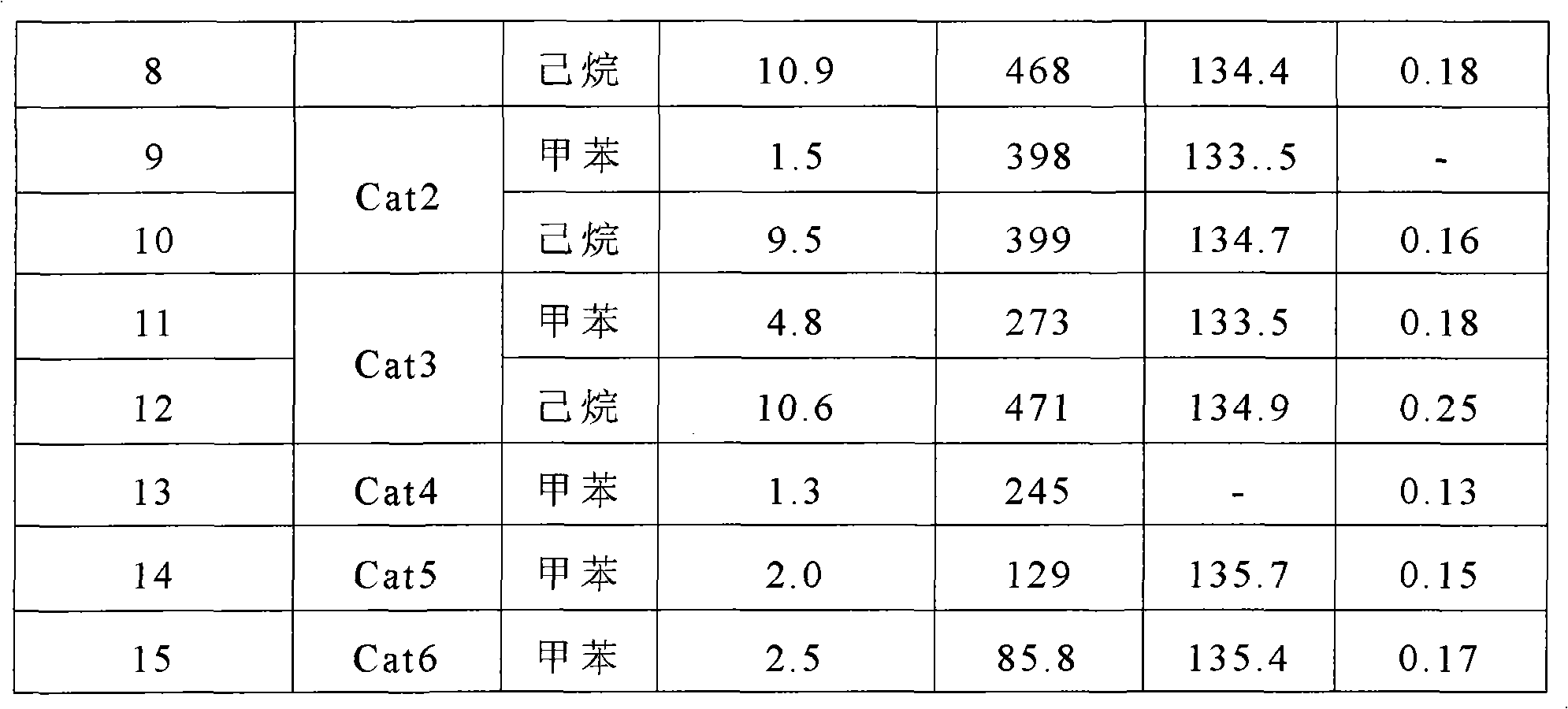

[0023] Dry 1.0 g of mesoporous molecular sieve MCM-41 with a pore size of 3.87 nm in a vacuum oven at a temperature of 120°C for 6 hours, add it to a loaded reaction bottle, add 50ml of toluene to suspend it, and stir it in a water bath at 50°C for 2 hours to make it Disperse evenly, add 3.3ml of 3mol / L tetrahydrofuran solution of methylmagnesium chloride, stir for 4 hours, filter, wash with toluene, and suspend in 50ml toluene again; in ice-water bath, add analytically pure phthalic acid di 0.2ml of isobutyl ester, stirred for 1 hour, added 2.0ml of titanium tetrachloride, continued to stir for 2 hours, raised the temperature to 50°C, continued to stir for 24 hours, filtered, washed with toluene, and dried in vacuum to obtain earthy gray catalyst powder, labeled It is cat1, the Ti content is 6.28wt%, and the Mg content is 8.68wt%.

Embodiment 2

[0025] The mesoporous molecular sieve MCM-41 with a pore size of 3.87nm in Example 1 was replaced with the mesoporous molecular sieve MCM-41 with a pore size of 4.50nm, and other conditions remained unchanged to obtain a gray catalyst powder, marked as cat2.

Embodiment 3

[0027] In Example 1, the mesoporous molecular sieve MCM-41 with a pore size of 3.87nm was replaced with a mesoporous molecular sieve SBA-15 with a pore size of 9.0nm, and other conditions remained unchanged to obtain a taupe catalyst powder, which was marked as cat3, Ti The Mg content is 4.75wt%, and the Mg content is 6.64wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com