Preparation of grafting modified starch sizing agent

A technology of modified starch and size, which is applied in fiber types, textiles and papermaking, fiber treatment, etc. It can solve environmental pollution and other problems, achieve good thermal stability of viscosity, low viscosity, and overcome poor wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

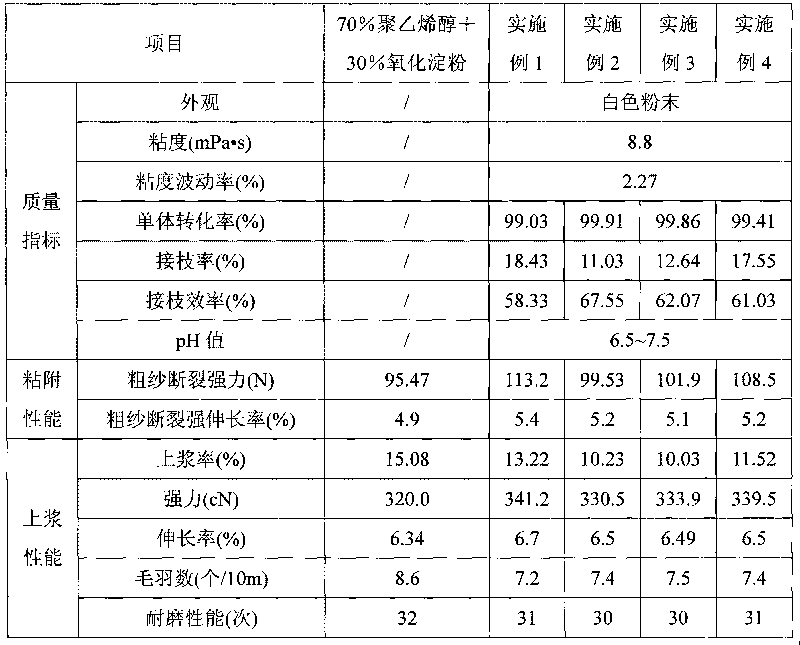

Embodiment 1

[0017] In the aqueous suspension of cornstarch with a mass percent concentration of 5%, add ethyl acrylate monomer with 5% starch mass, adjust the pH value to 3 with 0.5mol / L sulfuric acid, and then add redox initiator H 2 o 2 -FeSO 4 , H 2 o 2 and FeSO 4 The dosages are respectively 0.1% and 0.01% of the starch mass. Under nitrogen protection, stir and react at 45°C for 2.5 hours, adjust the pH value to 7 with 0.5mol / L sodium hydroxide solution, filter and fully wash with water, and dry Dry pulverization to obtain grafted modified starch slurry, the indexes of which are shown in Table 1.

Embodiment 2

[0019] In the potato starch aqueous suspension with a mass percent concentration of 20%, add ethyl acrylate monomer with 10% starch mass, adjust the pH value to 4 with 1.5mol / L sulfuric acid, and then add redox initiator H 2 o 2 -FeSO 4 , H 2 o 2 and FeSO 4 The dosages are respectively 1% and 0.2% of the starch mass. Under nitrogen protection, stir and react at 55°C for 3.5 hours, adjust the pH value to 6 with 1.5mol / L sodium hydroxide solution, filter and fully wash with water, and dry Dry pulverization to obtain grafted modified starch slurry, the indexes of which are shown in Table 1.

Embodiment 3

[0021] In the cassava starch aqueous suspension with a mass percent concentration of 30%, add ethyl acrylate monomer with a starch mass of 20%, adjust the pH value to 3.5 with 1mol / L sulfuric acid, and then add redox initiator H 2 o 2 -FeSO 4 , H 2 o 2 and FeSO 4 The dosages are 3% and 1% of the starch mass respectively, under the protection of nitrogen, stir and react at 50°C for 3 hours, adjust the pH value to 6.5 with 1mol / L sodium hydroxide solution, filter and fully wash with water, and dry Pulverize to obtain the grafted modified starch slurry, and its indexes are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com