Method for actively reinforcing wide-span concrete case beam bridge web

A concrete box girder and long-span technology, applied in bridge reinforcement, bridge, bridge construction, etc., can solve problems such as inapplicable tensioning method, difficulty in laying out tensioning equipment, and inability to improve the use stress condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Taking the reinforcement of the concrete continuous box girder bridge web of Lanxi Huangpan Bridge in Zhejiang Province as an example below, the specific implementation method of the present invention will be described in detail.

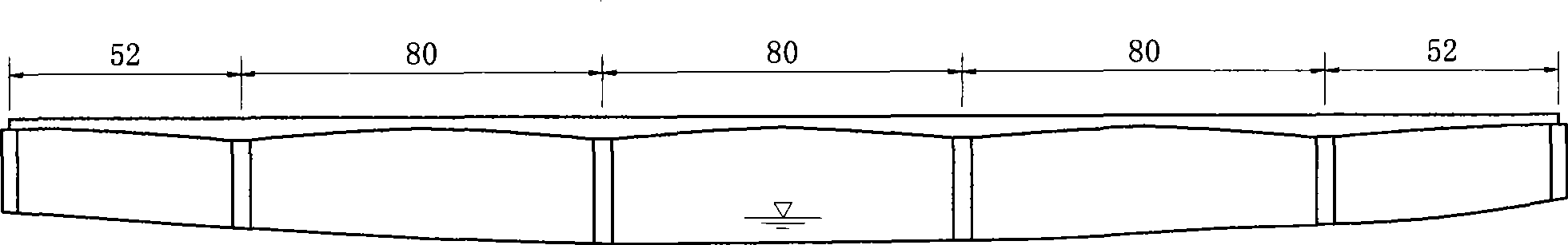

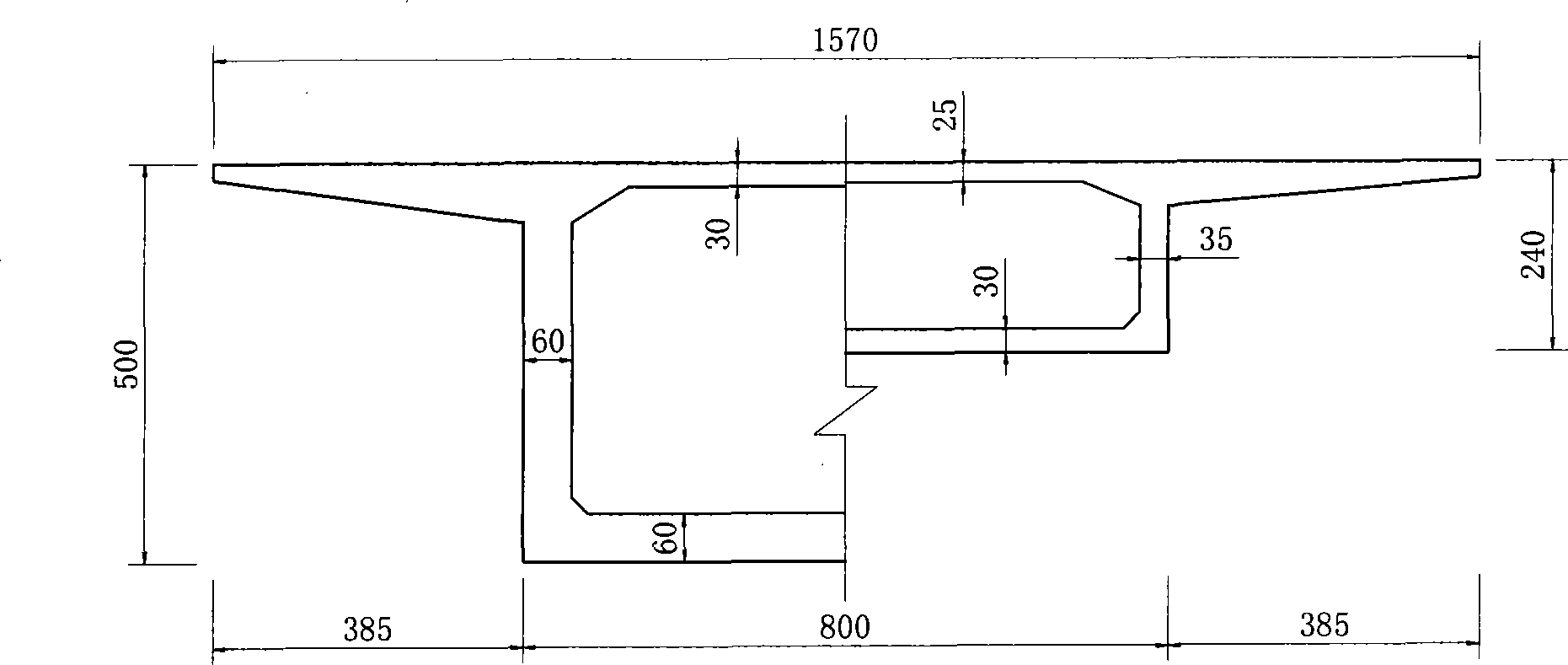

[0040] Lanxi Huangpan Bridge in Zhejiang Province is located on the Lanjiang River to the west of Lanxi City. It was completed and opened to traffic in July 1997. The main bridge of the bridge is 344m long, and the span combination is 52m+3×80m+52m. The upper structure is a prestressed concrete continuous box girder bridge, the box girder is made of C50 concrete, single box and single chamber section, the box width is 8m, the top width of the box girder is 15.7m, the width of the flange plate is 3.85m, the height of the fulcrum box girder is 5m, the height of the mid-span beam is 2.4m m, the web thickness gradually changes from 60cm at the fulcrum to 35cm at the mid-span, see the main structural dimensions figure 1 and figure 2 shown.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com