Fiber-reinforced plastic anchored net and machining process

A technology of fiber reinforced plastics and fiber reinforced materials, which is used in the installation of anchor rods, infrastructure engineering, excavation, etc., can solve the problems of low tensile strength and limited strength of coated concrete, anchor nets, etc. High strength, increased roughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

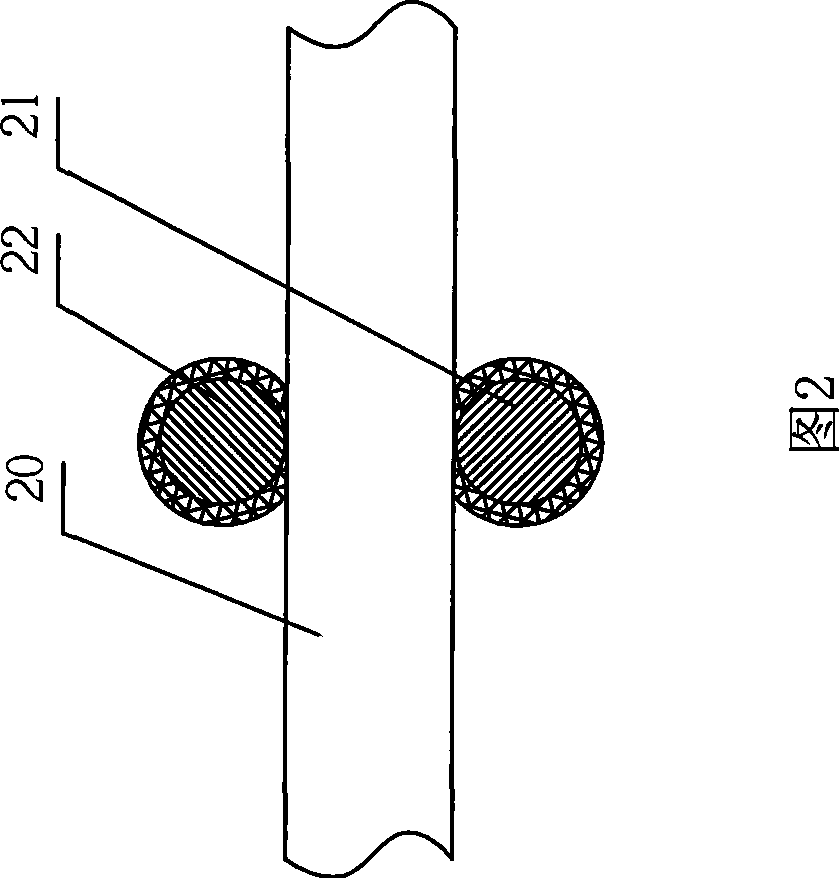

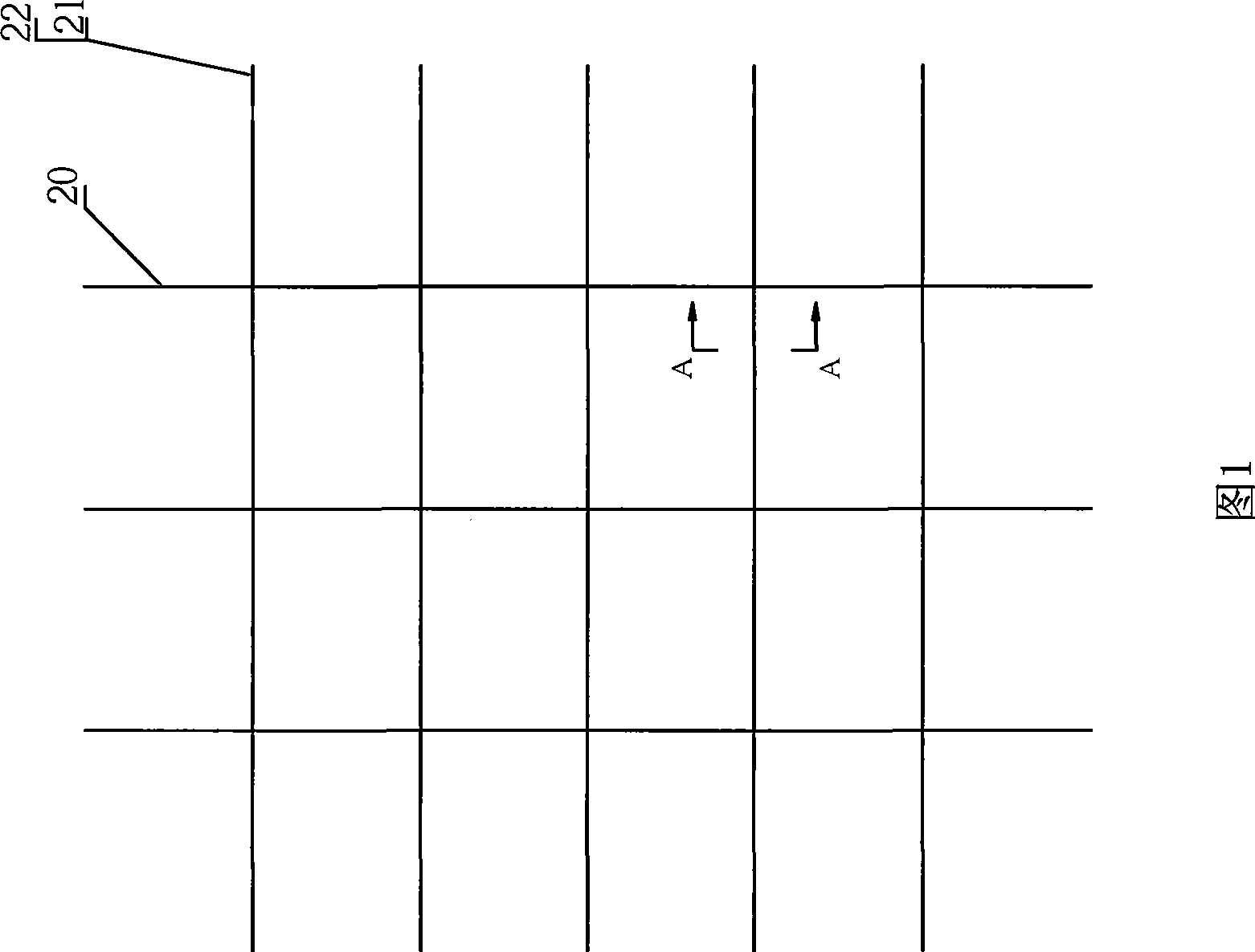

[0019] As shown in Fig. 1 and Fig. 2, the fiber reinforced plastic anchor net of the present invention is solidified by two layers of warp direction fiber reinforcement materials 21, 22 and a weft direction fiber reinforcement material 20 sandwiched between the two layers of warp direction fiber reinforcement materials Composed together, fiber reinforced materials are based on thermoplastics and reinforced with glass fibers or basalt fibers or carbon fibers.

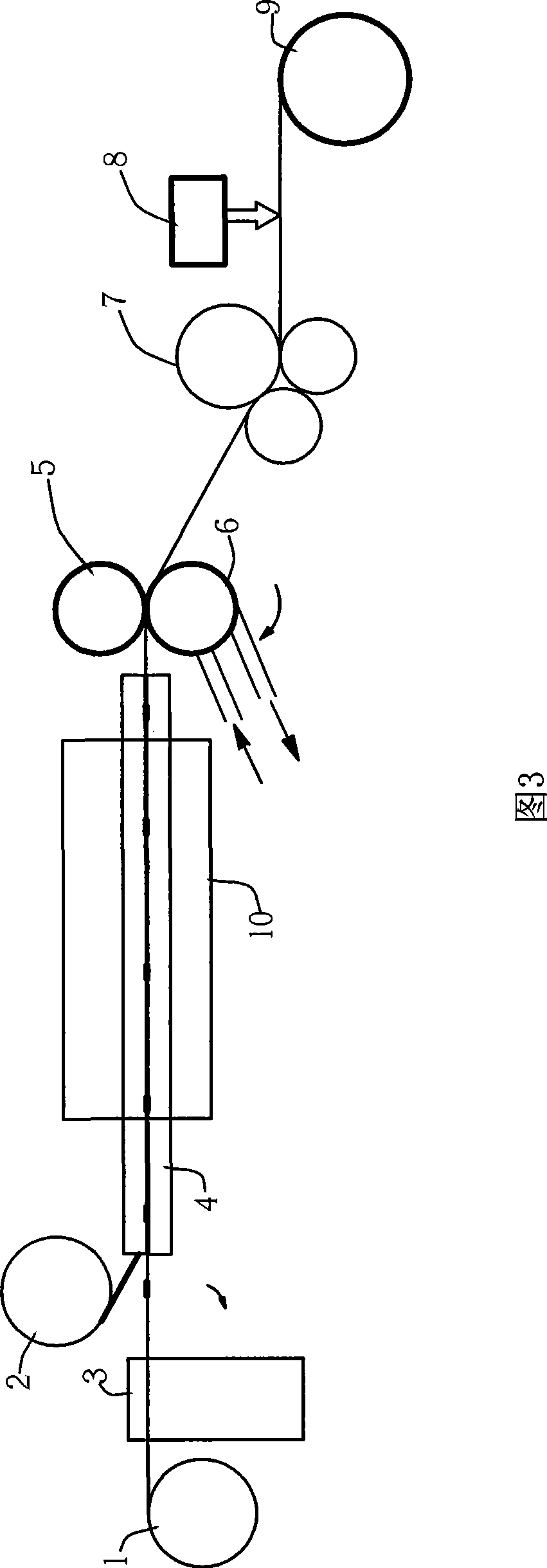

[0020] As shown in Figure 3 and Figure 4, it is a production process flow chart of the glass fiber reinforced plastic anchor net. The lower warp fiber reinforced material 21, the upper warp fiber reinforced material 22 and the weft fiber reinforced material 20 are fiber reinforced materials with polypropylene as the matrix and glass fiber as the reinforced material impregnated, and the fiber reinf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com