Full optical fiber integrated optical power monitor and manufacturing method thereof

A production method and optical power technology, applied in the coupling of optical waveguides, electromagnetic wave transmission systems, electrical components, etc., can solve the problems of large mutual interference, difficult production methods, large volume, etc., and achieve the effect of reducing costs and low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In this embodiment, a single-mode 9 / 125um optical fiber is used.

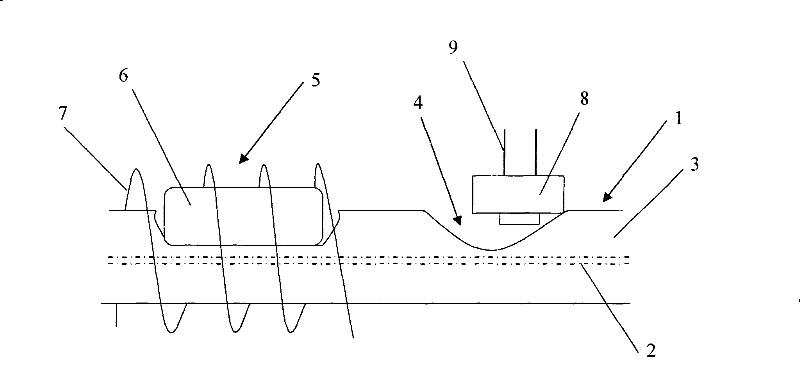

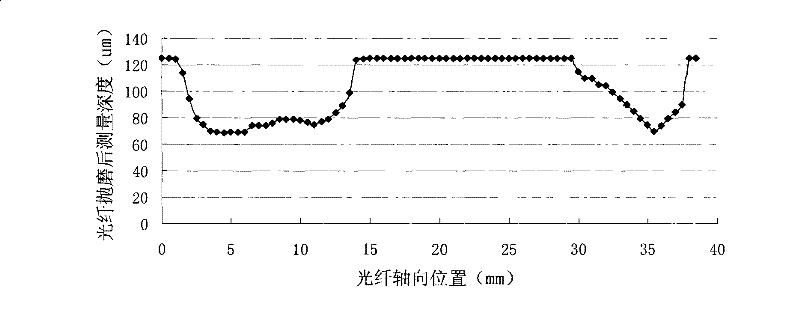

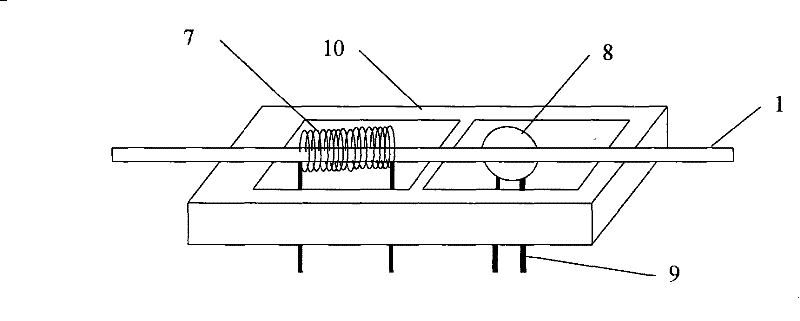

[0055] Such as figure 1 As shown, an all-fiber integrated optical power monitor of the present invention has a variable optical attenuator and an optical power monitor on the optical fiber 1 . The variable optical attenuator polishing area 5 covered with thermophotopolymer 6 is placed in a U-shaped groove (not shown in the figure), and the variable optical attenuator polishing area 5 is polished into a D-shaped fiber segment, which The polishing area is covered with a polymer 6 with a negative thermo-optic coefficient, and a heating resistance wire (also called an electrode) 7 is spirally wound around the periphery to form a variable optical attenuator. The polishing area 4 of the optical power monitor is polished into a V shape, and a photodetector 8 is arranged on the outside.

[0056] A method for manufacturing an all-fiber integrated optical power monitor includes the following steps:

[0057] (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com