Solid state cooling or power generating device and method of fabricating the same

A solid-state cooling and device technology, applied in thermoelectric devices, electro-solid devices, electrical components, etc., can solve the problem of low device efficiency, reduce size, and ensure robustness and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

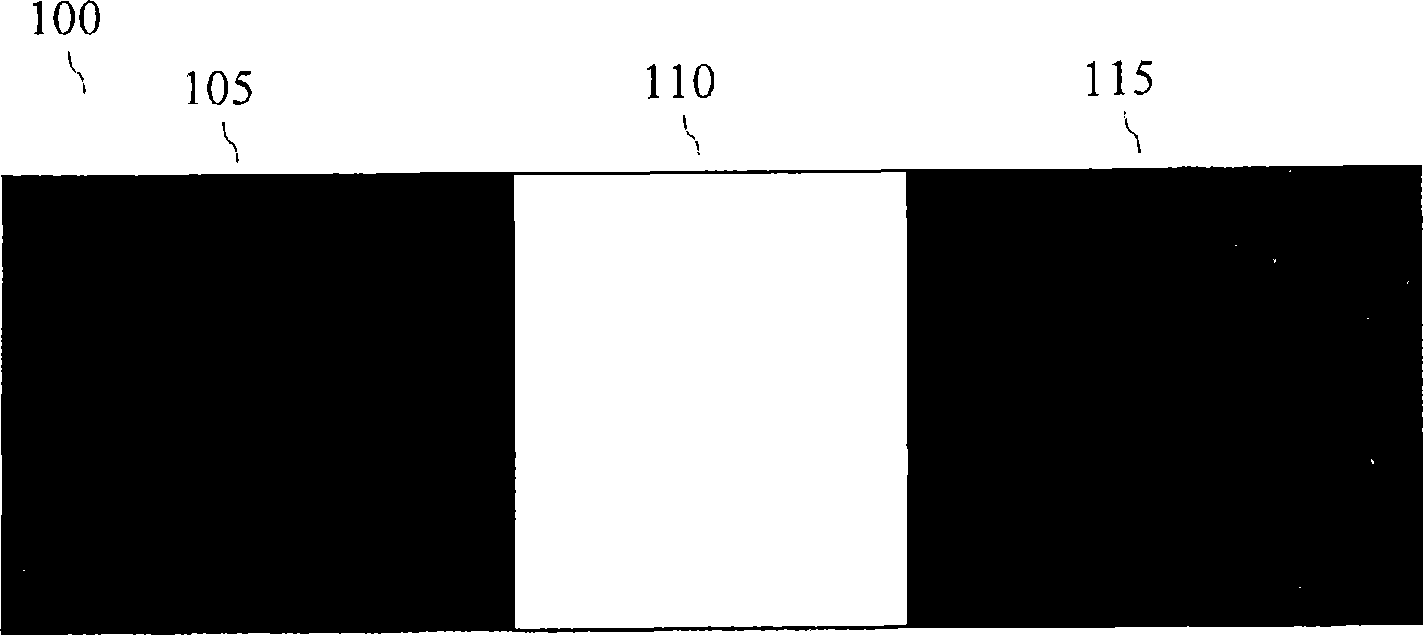

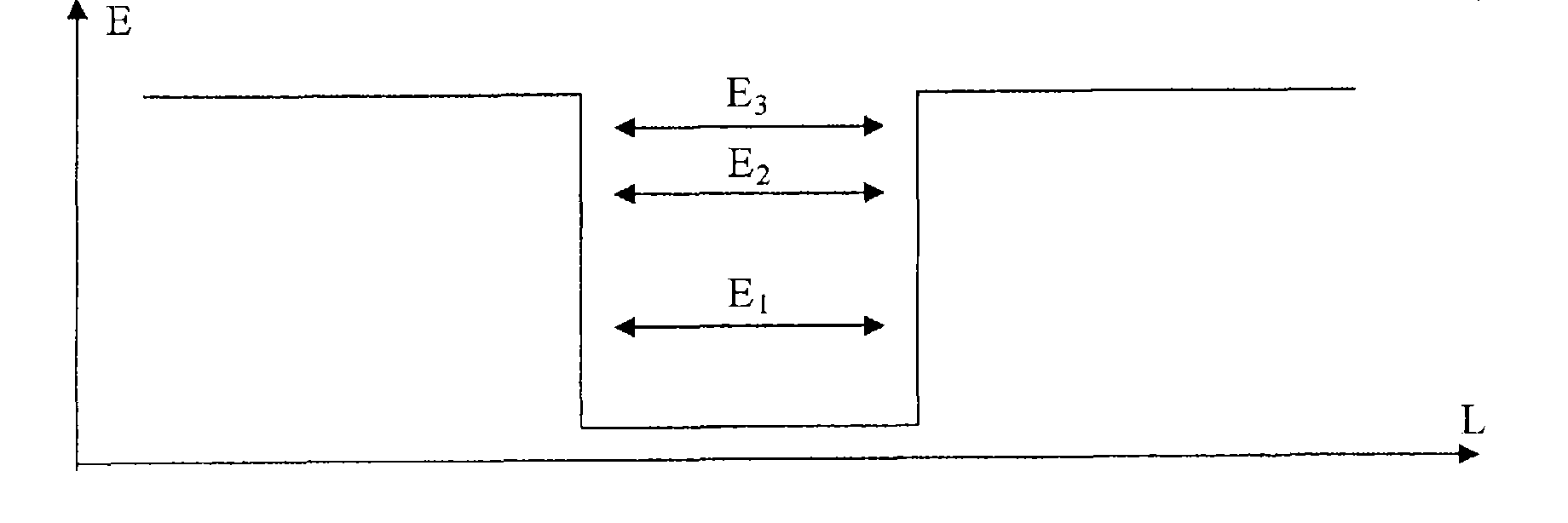

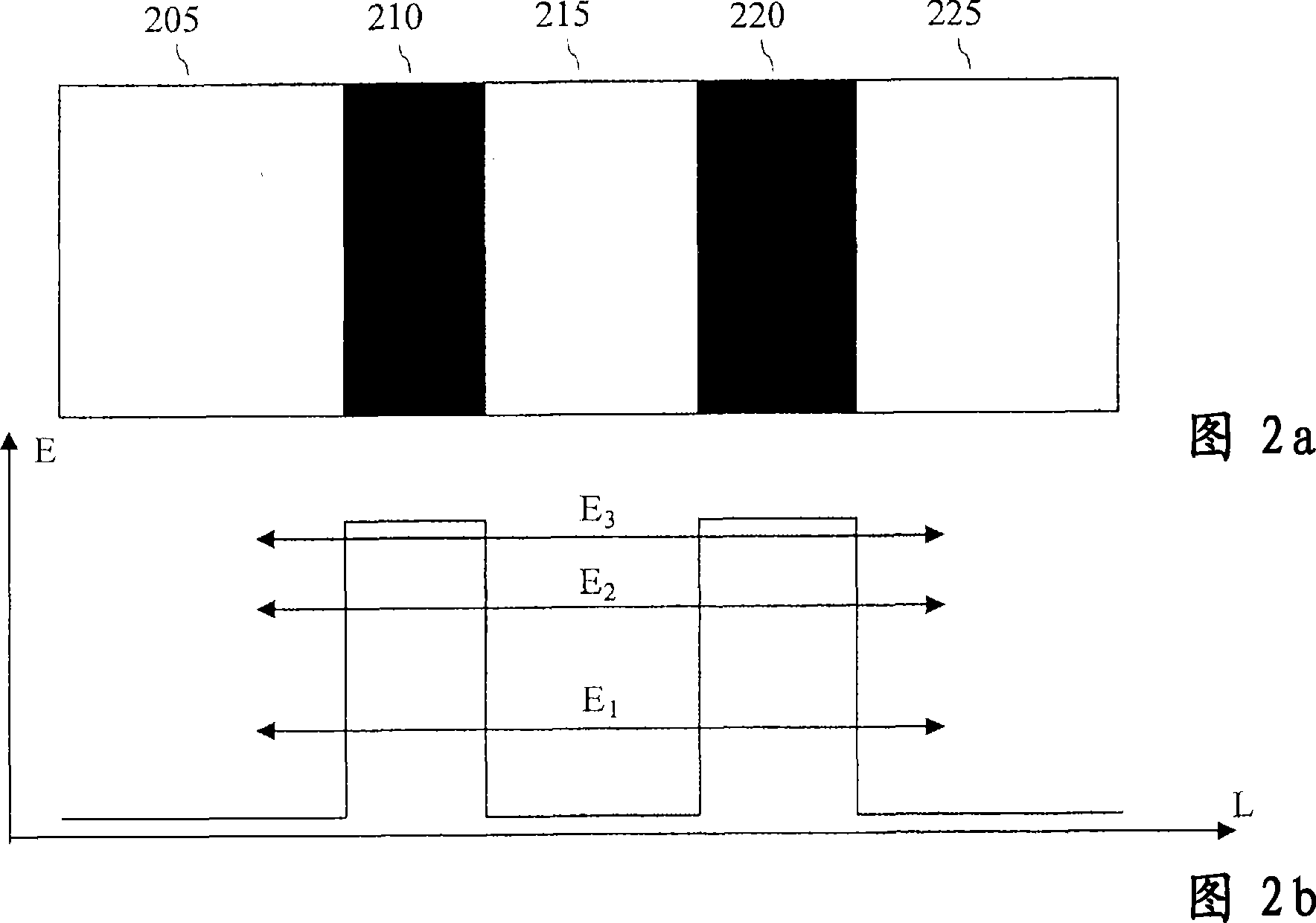

[0036] Tunneling vacuum gap heat pumps as discussed in the background section have the potential to deliver very high efficiencies compared to Peltier elements in eg cooling devices. However, it has been shown that the desired theoretical calculations and simulations are difficult to achieve with existing fabrication methods. The main problem with vacuum gap heat pumps proposed in the art lies in the requirement 1 -50 order of magnitude vacuum gap and about 1cm 2 area to be able to provide commercially interesting products. Providing such large electrodes with gaps of this magnitude is not possible with today's known methods, at least with regard to acceptable yields. Surface roughness, impurities, etc. will inevitably cause large variations in the gap width, and may cause contact between electrodes at some point to seriously impair the function of the heat pump.

[0037] According to the invention, a nanoscale semiconductor heterostructure is provided on at least one el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com