Negative type infrared light responsive composition, negative type printing plate and method of use thereof

A composition and infrared light technology, applied in the field of printing plates, can solve the problems of unstable plate quality, etc., and achieve the effects of good preservation performance, high printing resistance, and good repayment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

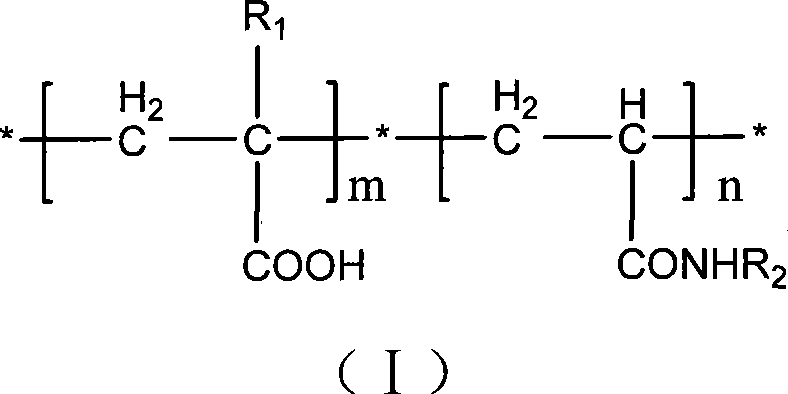

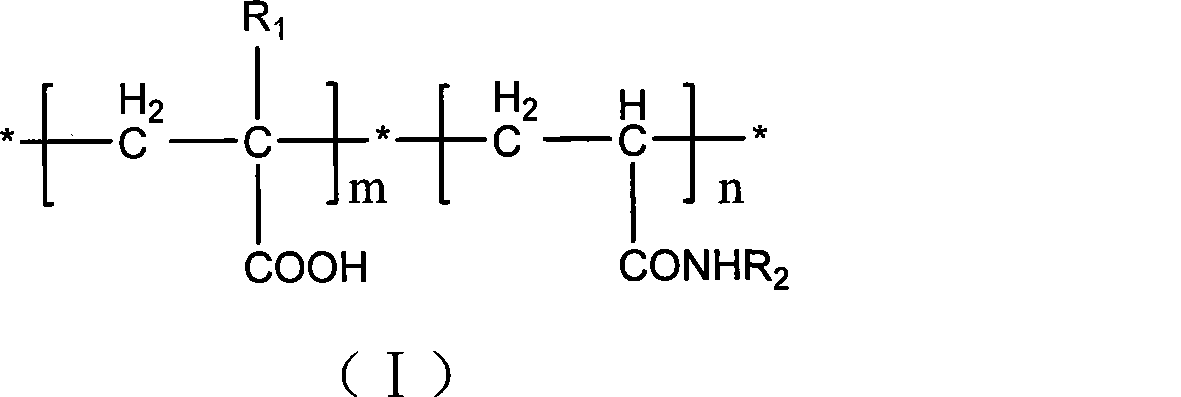

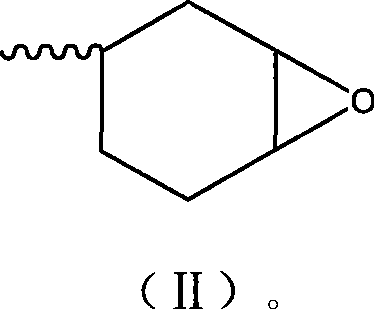

[0035] (1) Preparation of Infrared Sensitive Composition

[0036] (a) Synthesis of hydrophilic polymer I: Add 500ml of absolute ethanol in a 1L four-necked round-bottomed flask equipped with a sealed mechanical stirring device, a reflux condenser, a dropping funnel, and a nitrogen inlet tube, start stirring, and feed Dry nitrogen and bubble through for 15 min. Heat the water bath to 60°C. After the temperature is constant, add dropwise a solution consisting of 144g of acrylic acid (2mol), 142g of acrylamide (2mol), 1g of benzoyl peroxide and 200ml of absolute ethanol from which the polymerization inhibitor has been removed, for 30 minutes Drip finished. After maintaining the reaction at 60° C. for 5 hours, 1 g of benzoyl peroxide was added to maintain the temperature, and the reaction was continued for 10 hours before the reaction was terminated. The reaction mixture was naturally cooled to room temperature.

[0037] The cooled reaction solution was dropped into 5 L of acet...

Embodiment 2

[0058] (1) Preparation of Infrared Sensitive Composition

[0059] (a) Synthesis of Hydrophilic Polymer II: Add 500ml of absolute ethanol to a 1L four-necked round-bottomed flask equipped with a sealed mechanical stirring device, a reflux condenser, a dropping funnel, and a nitrogen inlet tube, start stirring, and feed Dry nitrogen and bubble through for 15 min. Heat the water bath to 60°C. After the temperature is constant, add dropwise a solution consisting of 129g of methacrylic acid (1.5mol), 213g of acrylamide (3mol), 1g of benzoyl peroxide and 300ml of absolute ethanol from which the polymerization inhibitor has been removed. , 30 minutes to drop. After maintaining the reaction at 60° C. for 5 hours, 1 g of benzoyl peroxide was added to maintain the temperature, and the reaction was continued for 10 hours before the reaction was terminated. The reaction mixture was naturally cooled to room temperature.

[0060] The cooled reaction solution was dropped into 5 L of aceto...

Embodiment 3

[0081] (1) Preparation of Infrared Sensitive Composition

[0082] (a) Synthesis of Hydrophilic Polymer III: Add 500ml of absolute ethanol to a 1L four-necked round-bottomed flask equipped with a sealed mechanical stirring device, a reflux condenser, a dropping funnel, and a nitrogen inlet tube, start stirring, and feed Dry nitrogen and bubble through for 15 min. The water bath was heated to 60°C, and after the temperature was constant, a solution composed of 172g methyl acrylate (2mol), 213g acrylamide (3mol), 1g benzoyl peroxide and 300ml absolute ethanol from which the polymerization inhibitor had been removed was added dropwise, 30 minutes to drip. After maintaining the reaction at 60° C. for 5 hours, 1 g of benzoyl peroxide was added to maintain the temperature, and the reaction was continued for 10 hours before the reaction was terminated. The reaction mixture was naturally cooled to room temperature.

[0083] The cooled reaction solution was dropped into 5 L of aceton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com