Anaerobic adsorption dephosphorization and denitrification process

An oxygen adsorption and denitrification technology, which is applied in aerobic and anaerobic process treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of increasing investment and operating costs, slow growth of nitrifying bacteria, pollution Low sludge concentration and other problems, to achieve the effect of reducing investment and operation costs, high treatment capacity, and increasing sludge concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

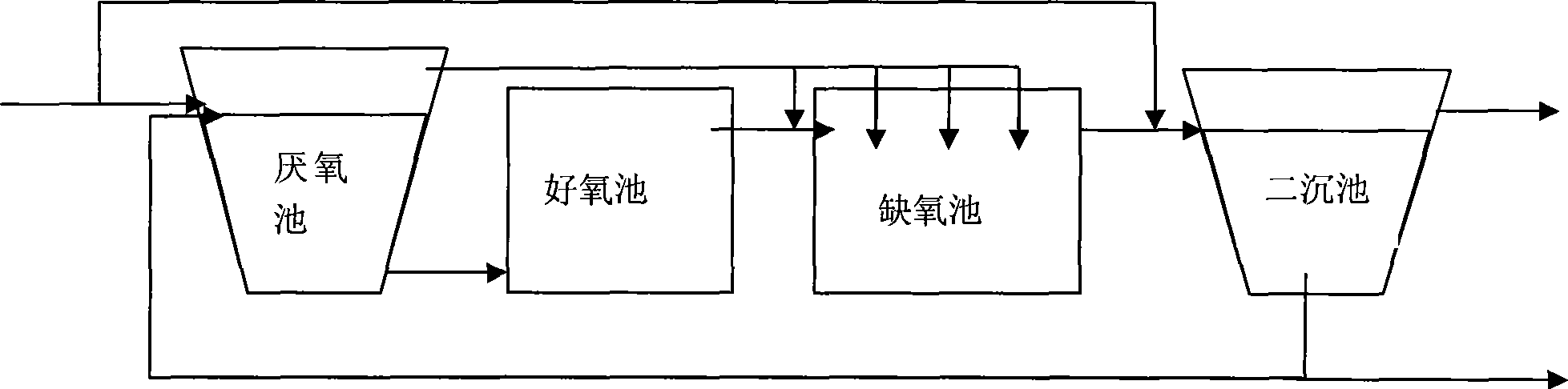

[0013] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0014] The process of the present invention divides the sewage into the anaerobic tank and the secondary settling tank at the same time, the proportion of sewage entering the secondary settling tank is 5% to 20%, and part of the sludge backflow in the secondary settling tank is mixed with the rest of the wastewater into the anaerobic tank , the return flow of part of the sludge entering the anaerobic tank is 0.5 to 1 times the amount of sewage entering the anaerobic tank. The supernatant after sedimentation in the anaerobic tank surpasses the aerobic tank and directly enters the anoxic tank or enters the anoxic tank at 1 to 19 water inlet points. The concentrated and sedimented bottom flow sludge in the anaerobic tank undergoes anaerobic phosphorus release process After entering the aerobic tank for ammonification and nitrification, the organic nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com