Constructed wetland filler and preparation method thereof and constructed wetland system

A technology of artificial wetland filler and artificial wetland system, which is applied in the field of environmental management, can solve problems such as insufficient decontamination ability, and achieve the effects of preventing and controlling the loss of microorganisms, improving the decontamination ability, and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

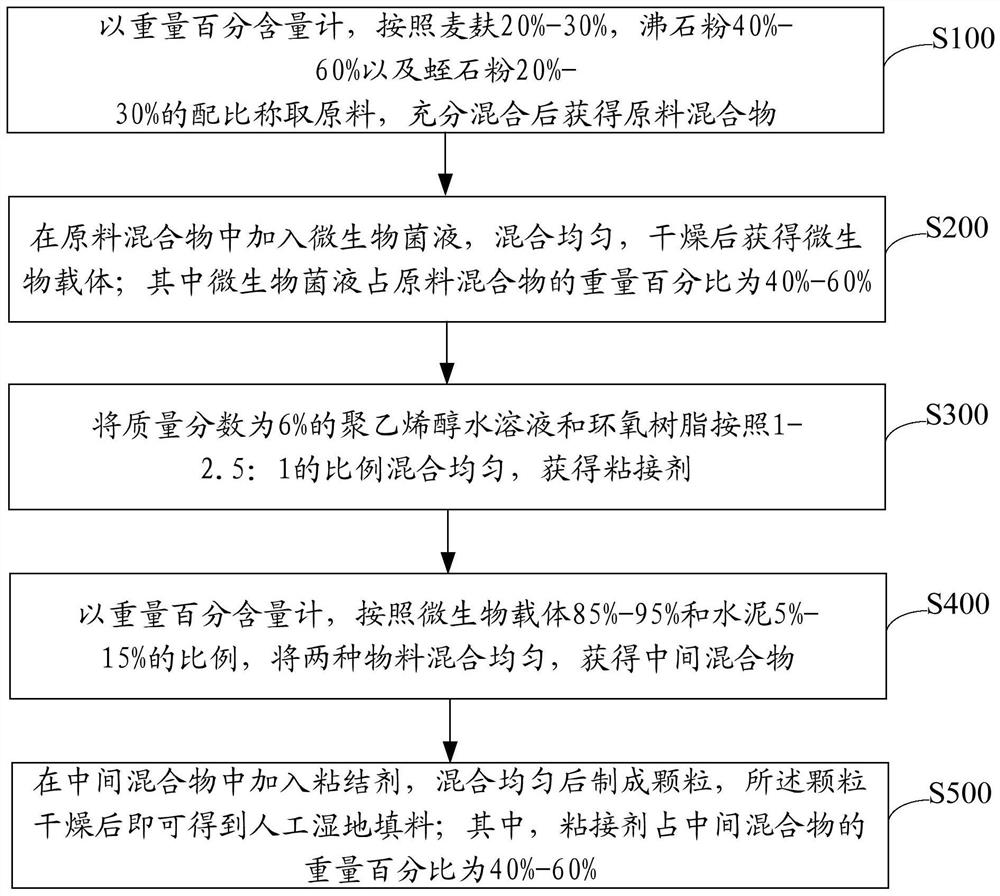

[0040] In this embodiment, the preparation method of artificial wetland filler comprises the following steps:

[0041] In step S100, the raw materials are weighed according to the ratio of 20%-30% of wheat bran, 40%-60% of zeolite powder and 20%-30% of vermiculite powder, and fully mixed to obtain a raw material mixture.

[0042] Among them, wheat bran, zeolite powder and vermiculite powder are all 100-200 mesh powders.

[0043] Step S200, adding microorganism liquid to the raw material mixture, mixing evenly, and drying to obtain a microbial carrier; wherein the weight percentage of the microbial liquid to the raw material mixture is 40%-60%.

[0044] In this step, the microbial bacterial liquid can be added to the raw material mixture, mixed evenly, and then dried at 45°C to obtain the microbial carrier. The microorganisms in the microbial liquid are several or one of Bacillus subtilis, Bacillus licheniformis, Bacillus amyloliquefaciens, Paracoccus denitrificans, yeast, Nit...

Embodiment 1

[0055] In this embodiment, the following steps are included:

[0056] In step S101, the raw materials are weighed according to the ratio of 30% of wheat bran, 40% of zeolite powder and 30% of vermiculite powder in terms of weight percentage, and are fully mixed to obtain a raw material mixture.

[0057] Step S102, adding the bacterial solution of Bacillus subtilis and Bacillus licheniformis to the raw material mixture, mixing evenly, and drying at 45°C to obtain a microbial carrier; wherein the bacterial solution of Bacillus subtilis and Bacillus licheniformis accounted for the weight of the raw material mixture The percentage is 40%.

[0058] Step S103 , uniformly mixing the polyvinyl alcohol aqueous solution with a mass fraction of 6% and the epoxy resin at a ratio of 1:1 to obtain an adhesive.

[0059] In step S104, the two materials are uniformly mixed according to the ratio of 85% of microbial carrier and 15% of weakly alkaline Portland cement in weight percentage to obt...

Embodiment 2

[0063] In this embodiment, the following steps are included:

[0064] In step S101 , in weight percent, the raw materials are weighed according to the ratio of 25% wheat bran, 50% zeolite powder and 25% vermiculite powder, and the raw material mixture is obtained after thorough mixing.

[0065] Step S102, adding bacterial solutions of Bacillus amyloliquefaciens and Paracoccus denitrificans to the raw material mixture, mixing evenly, and drying at 45°C to obtain microbial carriers; wherein the bacterial solutions of Bacillus subtilis and Bacillus licheniformis accounted for the raw material mixture The weight percentage is 50%.

[0066] Step S103 , uniformly mixing the polyvinyl alcohol aqueous solution with a mass fraction of 6% and the epoxy resin at a ratio of 2.5:1 to obtain an adhesive.

[0067] In step S104, the two materials are uniformly mixed according to the ratio of 95% of microbial carrier and 5% of weakly alkaline Portland cement in weight percentage to obtain an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com