Novel calcium / zinc composite heat stabilizer composition and use thereof

A composite heat stabilizer and composition technology, applied in the field of polymer materials, to achieve good compatibility and high stabilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

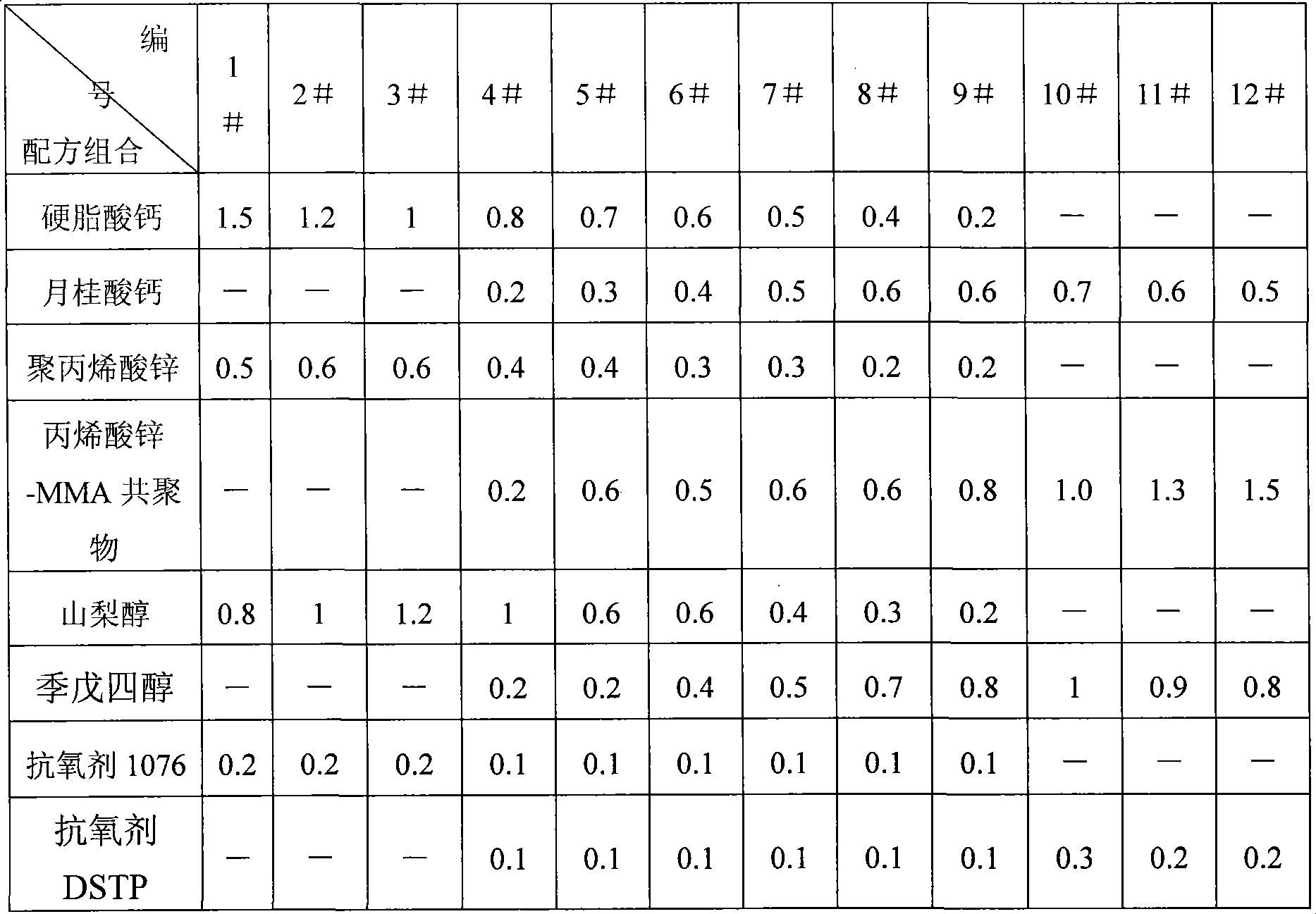

[0021] The zinc soap, calcium soap, polyol, and antioxidant are mixed uniformly in a high-speed mixer in proportion to prepare the calcium / zinc heat stabilizer composition of the present invention. The specific formula design is shown in Table 1.

[0022] Table 1 Heat stabilizer composition formula

[0023]

[0024] Remarks: MMA stands for methyl methacrylate; based on 100g of chlorine-containing resin, the units in the table are all g.

[0025] The composition prepared in the above example, 40 parts by mass of dioctyl phthalate (DOP) and 100 parts by mass of PVC resin (S-1000) are mixed uniformly in a high-mixer, and the roll temperature is 140°C and the roll distance Plasticized into pieces on a 1mm double-roll mixer, then cut pellets and fill them into test tubes, aged in an oil bath at 180°C, and then measure the static thermal stability according to the national standard GB / T2917.1-2002 Congo red method, and record the thermal stability time , The results are shown in Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com