Surface coated long persistence phosphor and preparation thereof

A long-lasting phosphor and surface coating technology, which is applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of easy aggregation, high oil absorption rate, poor compatibility, etc., achieve strong film binding force and reduce oil absorption rate , the effect of viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Select the chemical structure as Sr 0.95 Al 2 O 4 :Eu 0.02 , Dy 0.03 The long afterglow phosphor phosphor powder of ”is used as the coating object. Weigh 150g phosphor powder and place it in a container with a heating jacket. While stirring, heat the phosphor powder to 100°C, add 0.23g stearic acid, and continue to keep warm. After stirring for 5 minutes, take 0.3 g of isopropyl bis(glyceryl distearate) aluminate, pulverize and add to the phosphor, continue to stir for 5 minutes, stop heating, and cool to room temperature to obtain the coated Phosphor.

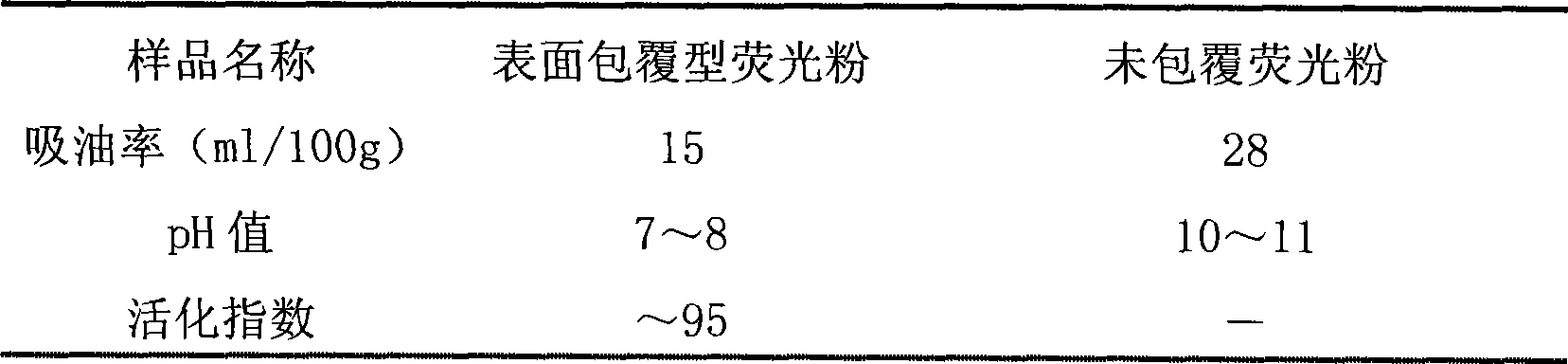

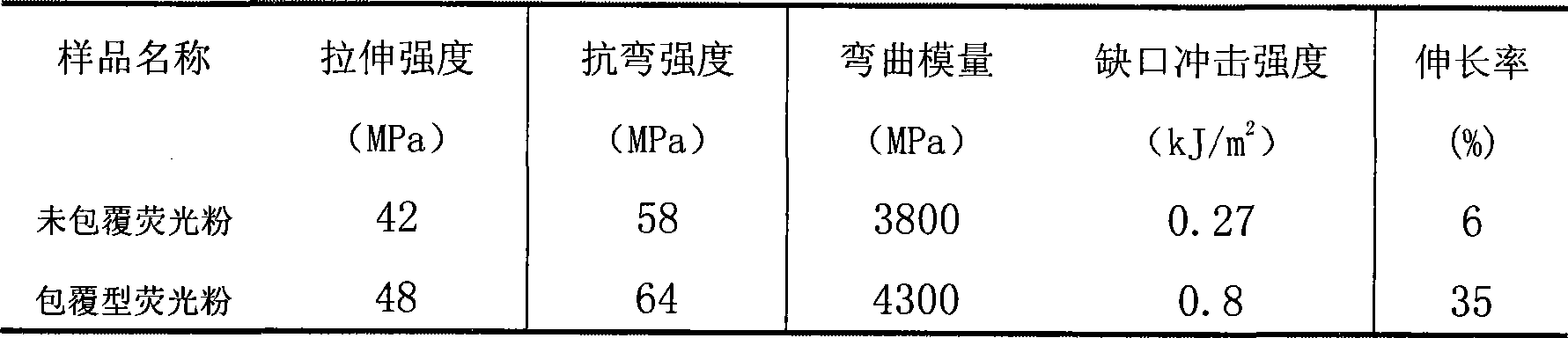

[0036] Table 1 Performance comparison before and after phosphor coating

[0037]

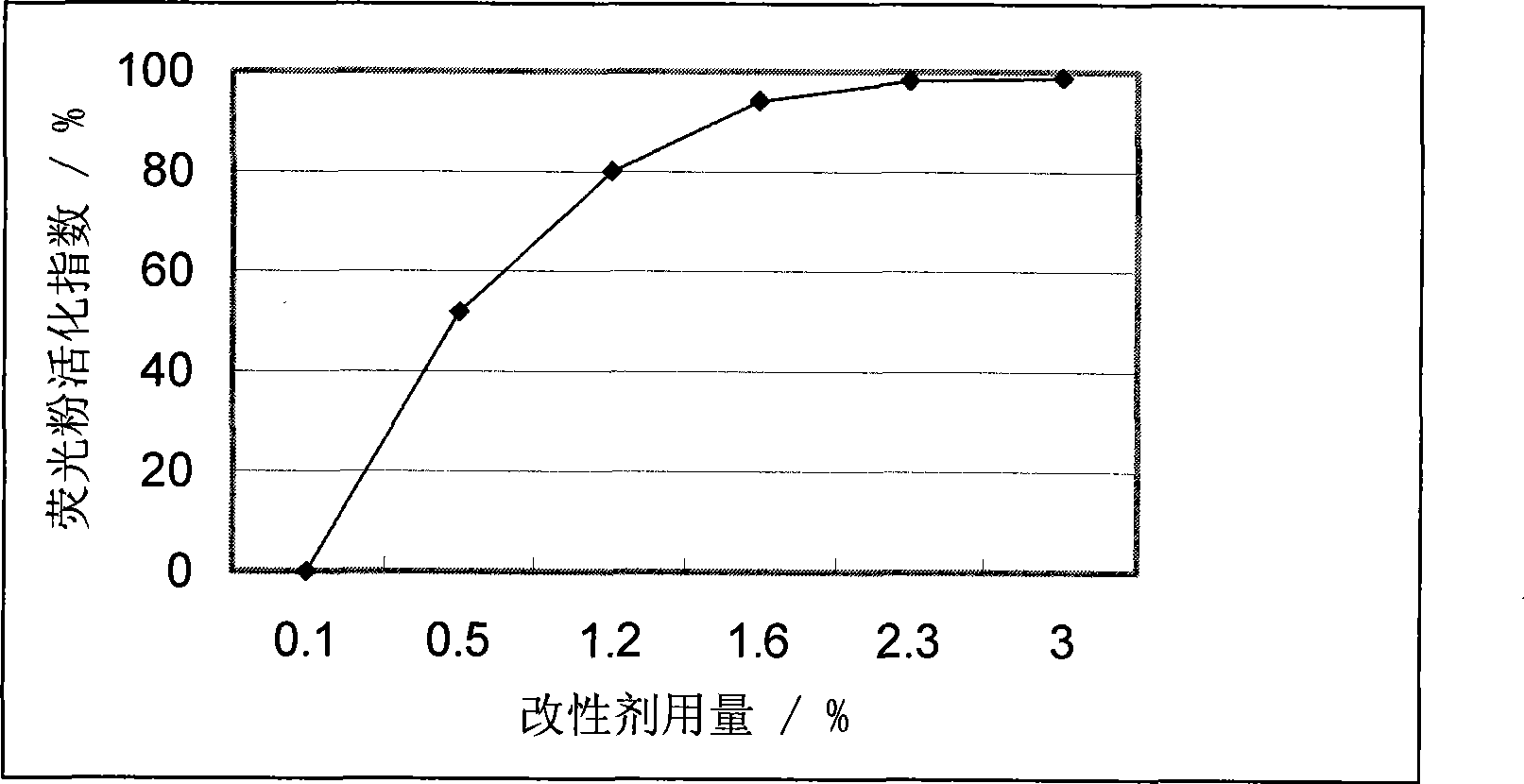

[0038] Table 1 lists several important performance indexes of the surface-coated phosphors and uncoated phosphors prepared in Example 1. It can be seen from the table that after surface coating, the phosphor oil absorption rate is effectively reduced, and the activation index is significantly increased.

Embodiment 2

[0040] Weigh the chemical structural formula as Sr 0.88 Al 2 O 4 :Eu 0.035 , Dy 0.085 Put 300g of the long afterglow phosphor phosphor powder in a container with a heating jacket, while stirring, heat the phosphor powder to 120℃, add 1.5g stearic acid, continue to keep warm and stir for 10 minutes, then take 3.6g Di(distearin diethylene glycol ester) isopropyl aluminate is pulverized and added to the phosphor. After stirring for 8 minutes, the heating is stopped, and the coated phosphor can be obtained by cooling to room temperature.

Embodiment 3

[0042] Take the chemical structural formula as Sr 3.982 Al 14 O 25 :Eu 0.006 , Dy 0.012Put 200g of the long afterglow phosphor powder in a container with a heating jacket. While stirring, heat the phosphor powder to 130°C, add 2.5g stearic acid, continue to keep the temperature and stir for 15 minutes, and then take 6.4g two ( The pentaerythritol tristearate (pentaerythritol ester) isopropyl aluminate is crushed and added to the phosphor. After stirring for 15 minutes, the heating is stopped, and the coated phosphor is obtained by cooling to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com