Novel aluminum cell structure

An aluminum electrolytic cell and electrolytic cell technology, applied in the field of new aluminum electrolytic cell structure, can solve problems such as staying in theoretical discussion, and achieve the effects of reducing aluminum electrolysis power consumption, reducing process pressure drop, and reducing power consumption per ton of aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

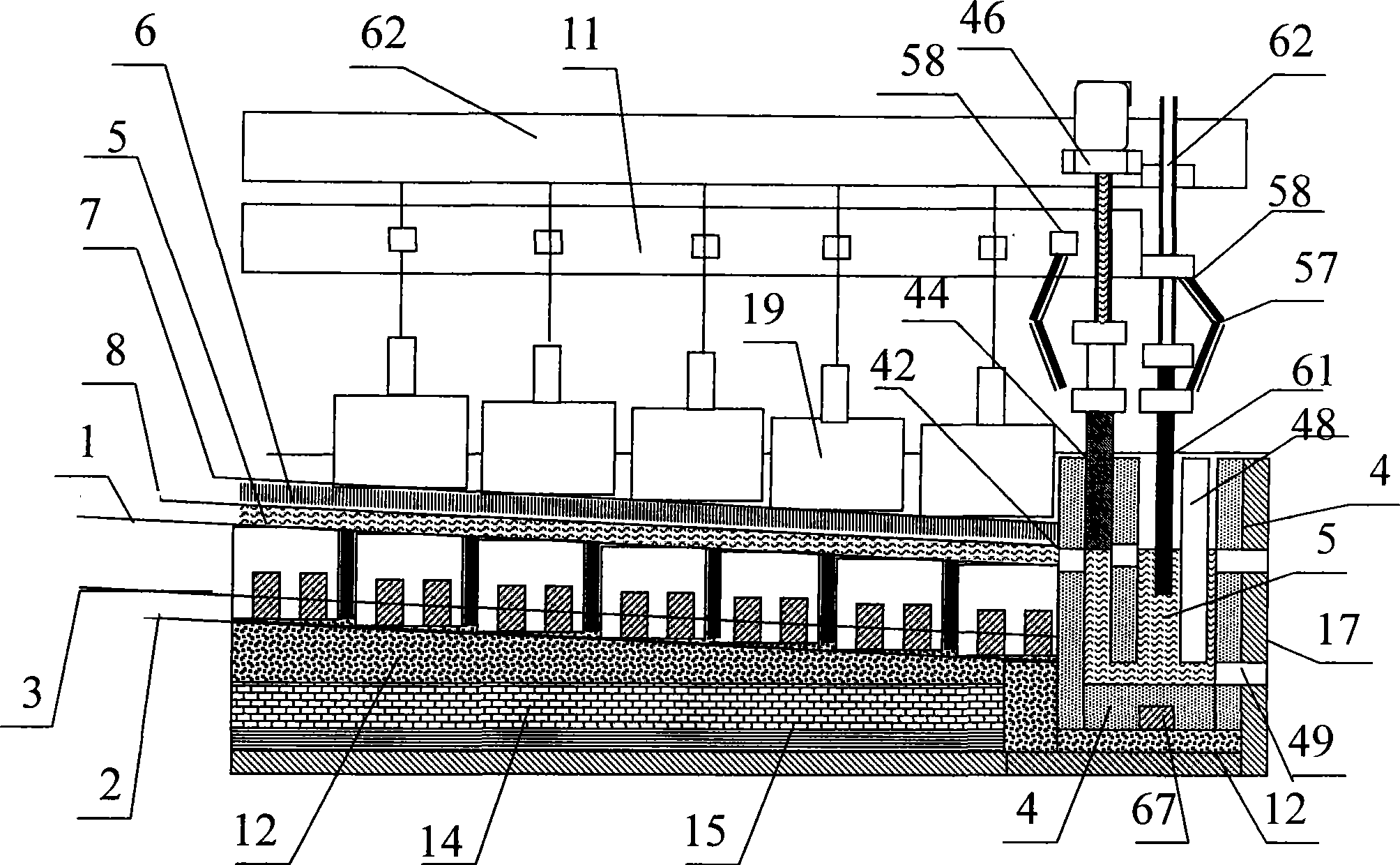

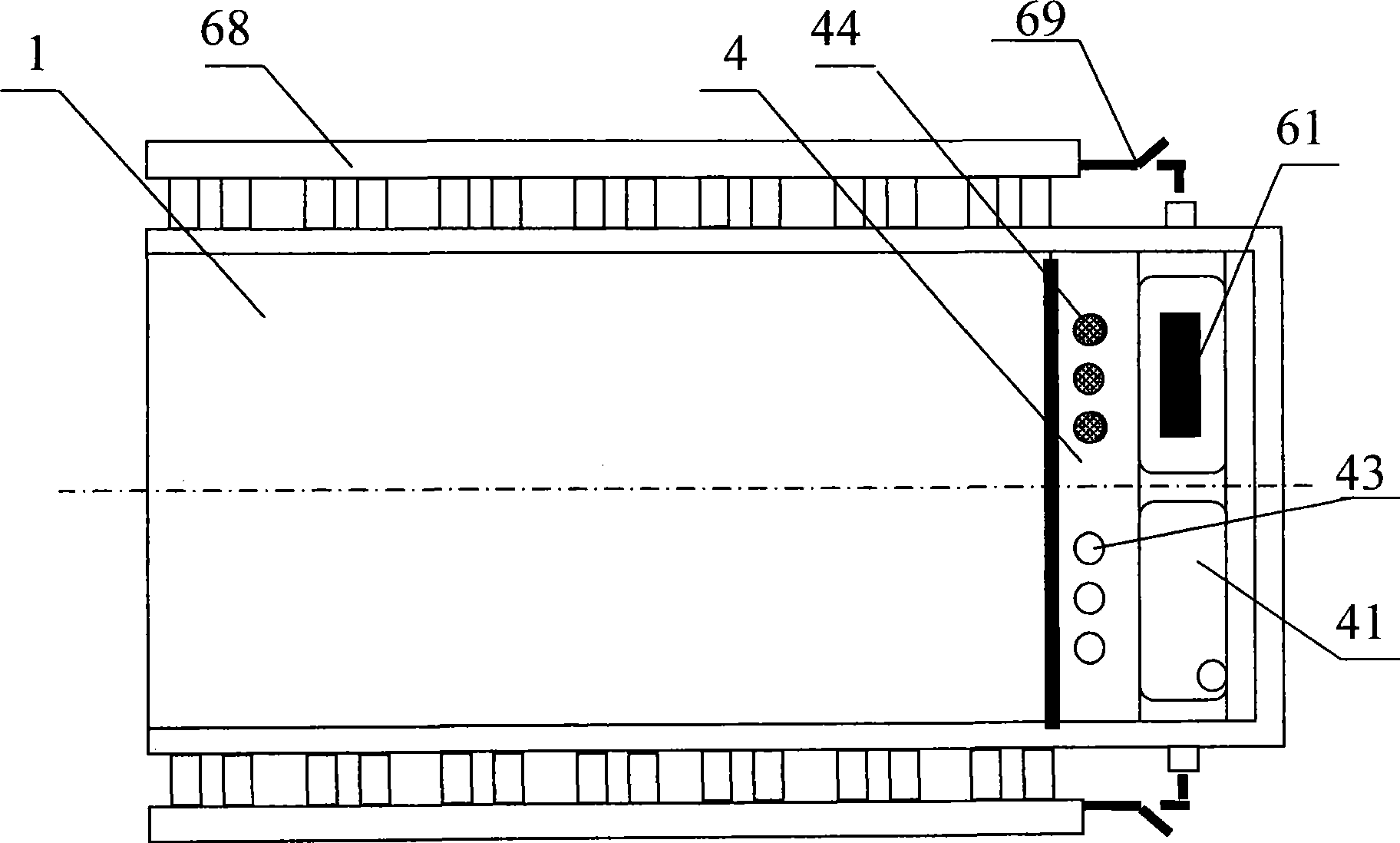

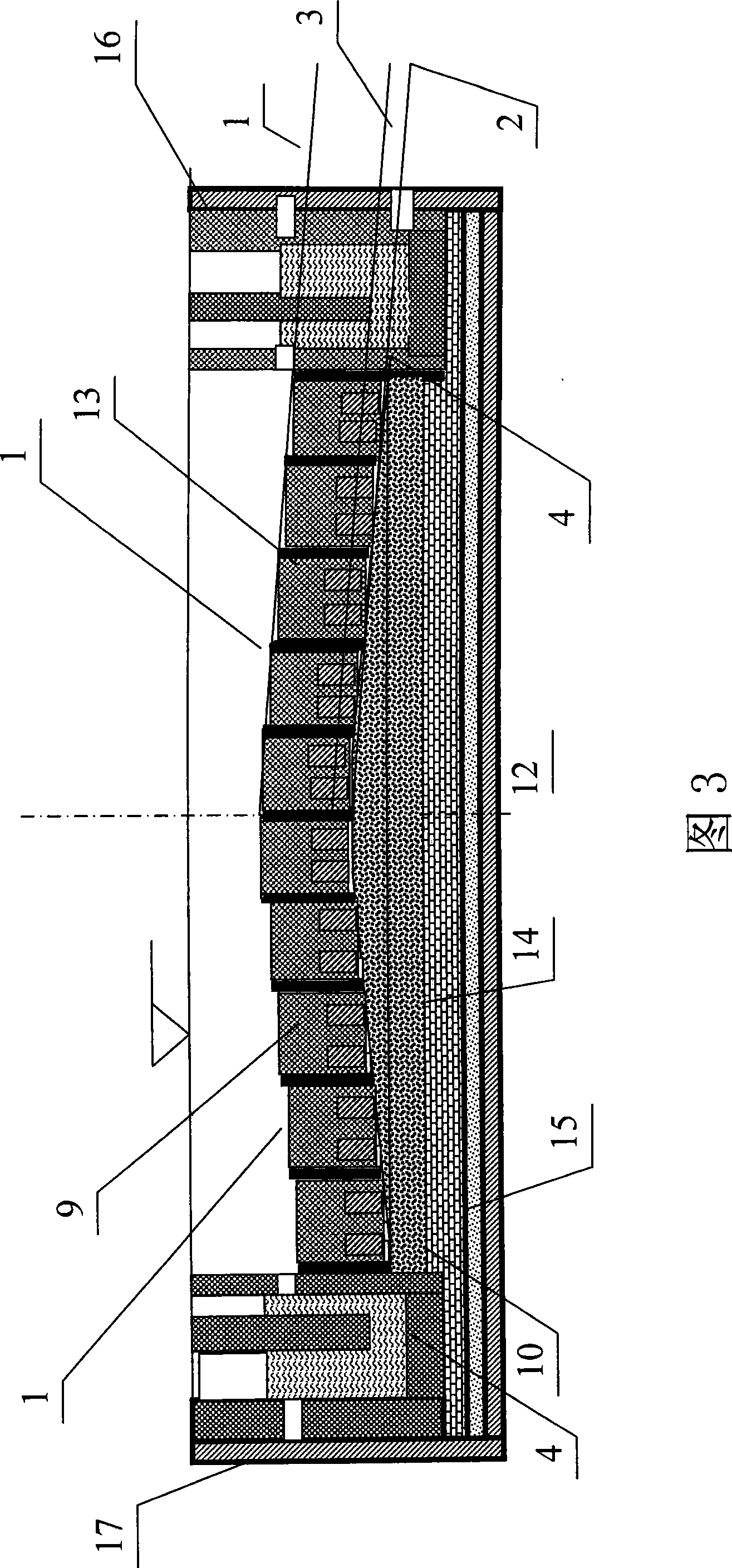

[0061] In order to be able to adjust and control the height of the aluminum liquid horizontal interface 8 of the aluminum liquid 5 in the electrolytic working condition, in the aluminum electrolytic cell liner, one end or both ends arranged along the axial direction of the large busbar 11 are placed in the channel steel shell 17 Inner thermal insulation layer 14 is constructed and installed with an overflow tank 4 that can adjust the temperature and height of the molten aluminum.

[0062] The adjustable aluminum liquid overflow tank 4 is provided with several intercepting devices that can adjust and control the level of the aluminum liquid in the electrolytic cell. 43 and cut-off rod 44 are formed, the flow-through hole 43 and the overflow hole 42 of the cathode carbon block in the electrolytic tank on the overflow tank 4 are connected vertically through the upper surface 1 of the electrolytic aluminum liquid 5 layers, and the cut-off rod 44 is connected with the flow-through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com