Large-range plane three-freedom degree precision fine motion device and control method thereof

A technology of micro-movement device and degrees of freedom, applied in measurement devices, microscopes, surface/boundary effects, etc., can solve the problems of complex detection system, increase the complexity of control system, limit the movement range of the platform, etc. Practicality and accuracy are easily guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

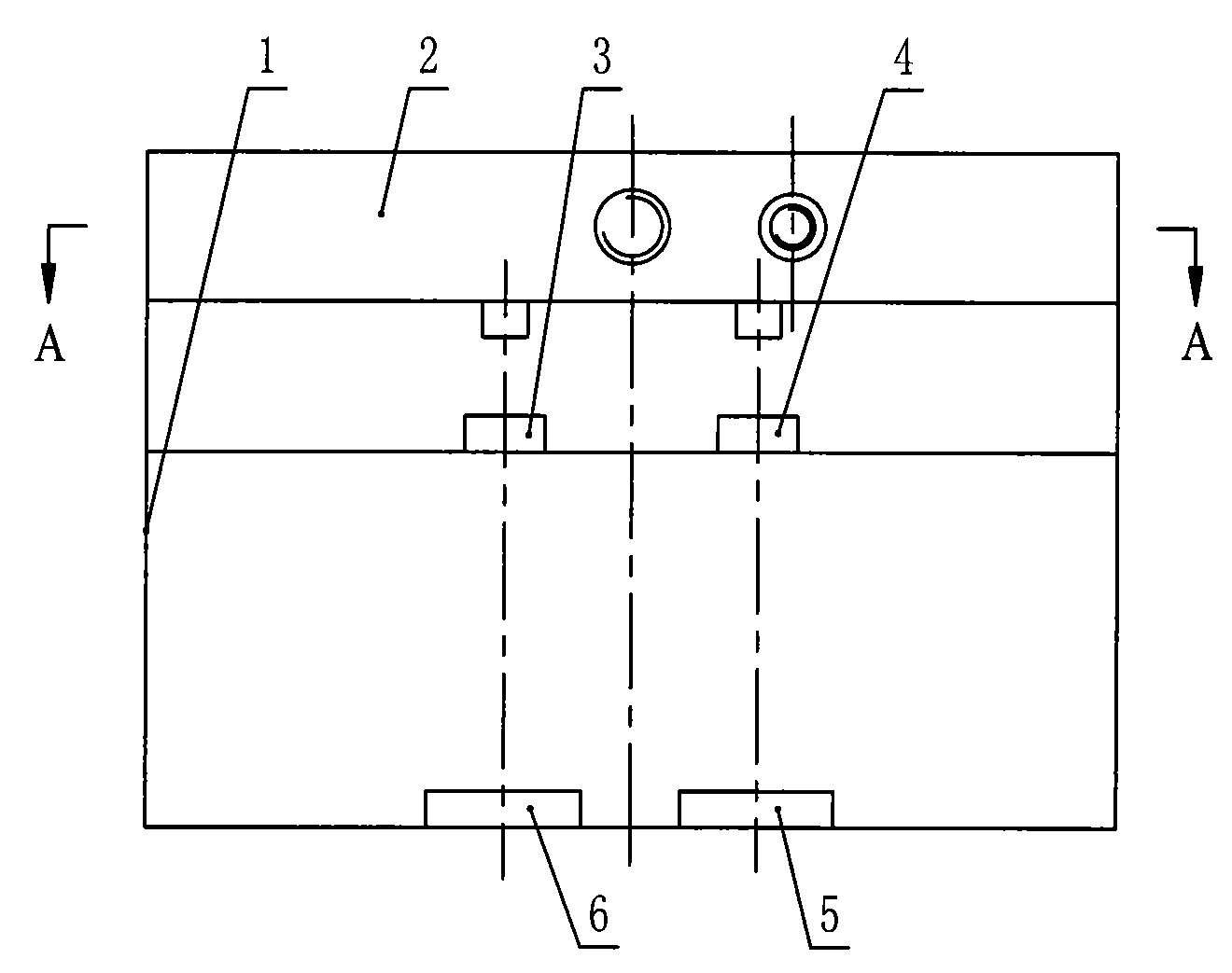

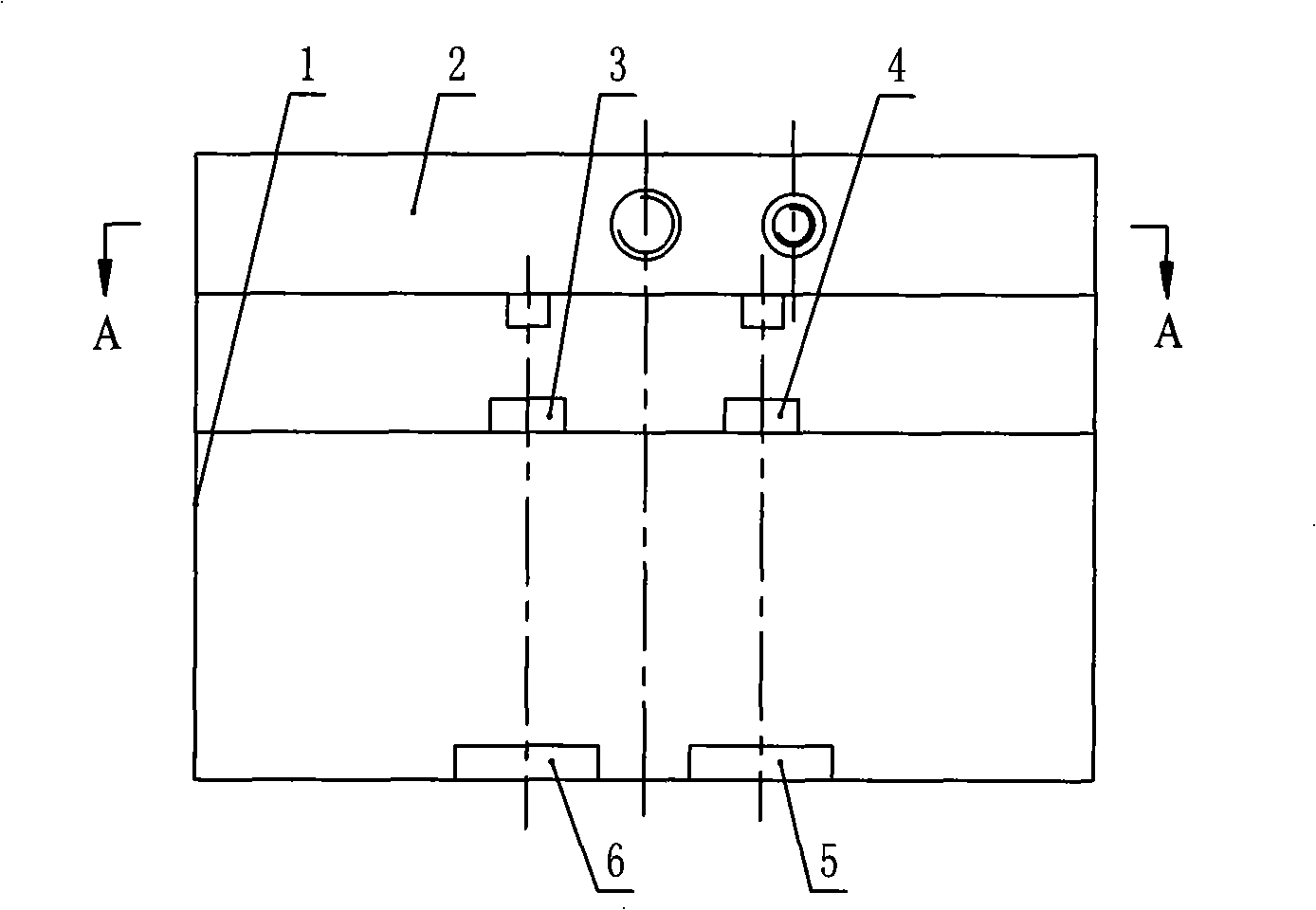

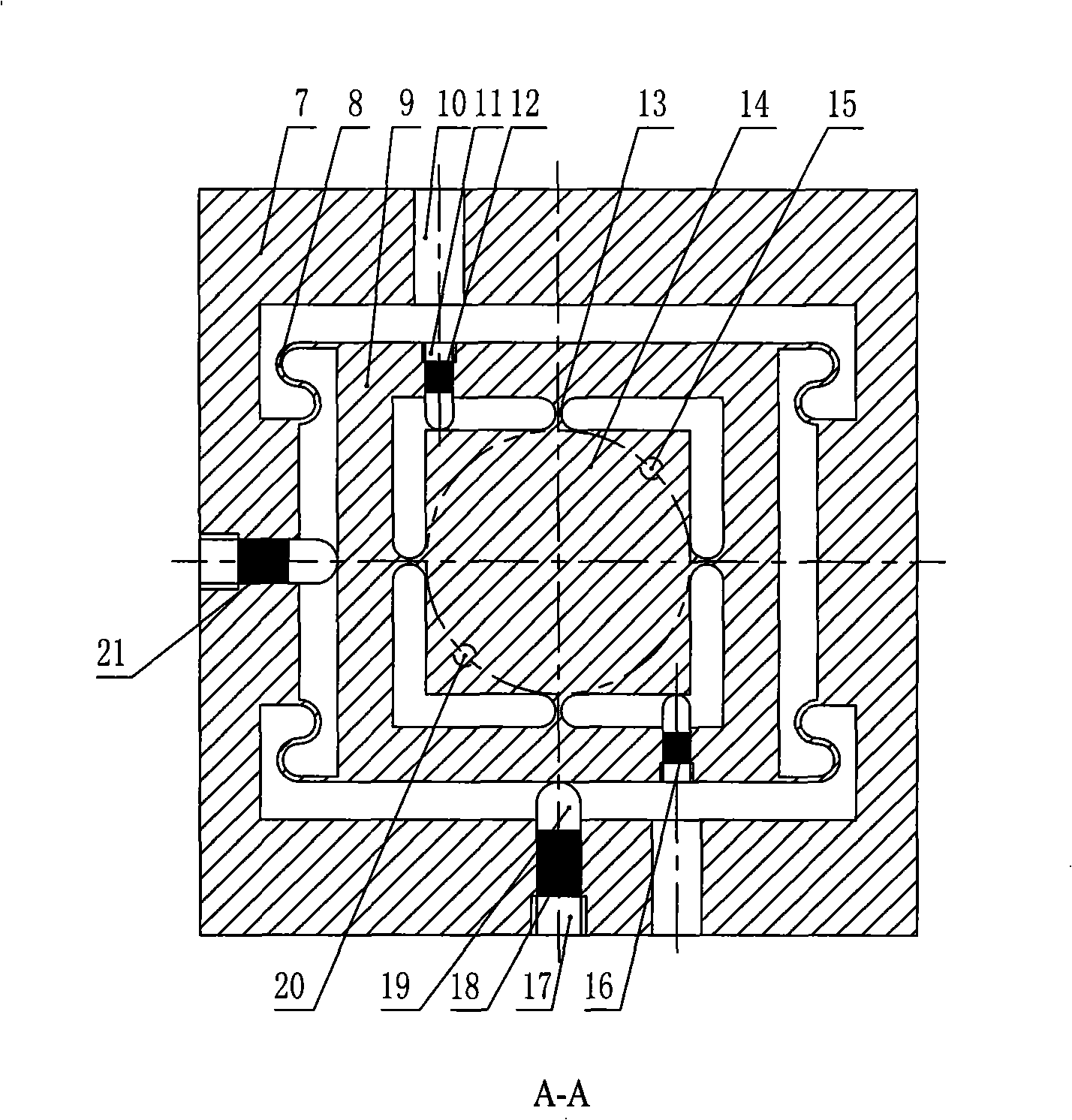

[0016] As shown in Fig. 1, the working platform 2, optical lenses 3, 4 and two-dimensional photoelectric position sensitive detectors 6, 5 are respectively installed on the support 1, the working platform 2 is installed on the top layer, and the optical lenses 3, 4 are installed on the middle layer, two-dimensional The photoelectric position sensitive detector 6,5 is contained in the bottom layer; the distance from the top layer to the middle layer is less than the focal length of the optical lenses 3,4, and the distance from the middle layer to the bottom layer is greater than the focal length of the optical lenses 3,4; the semiconductor laser 20, the optical lens 3 and the two-dimensional The photoelectric position sensitive detector 6 is on the same axis; the semiconductor laser 15, the optical lens 4 and the two-dimensional photoelectric position s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com