Innocent treatment of cyanide and fluoride in solid waste residues and recycling process thereof

A technology of harmless treatment and solid waste, which is applied in the direction of protective devices against harmful chemicals, etc., can solve problems such as farmland occupation and hidden dangers of the ecological environment, and achieve the effect of saving land use, simple equipment, and eliminating sources and hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

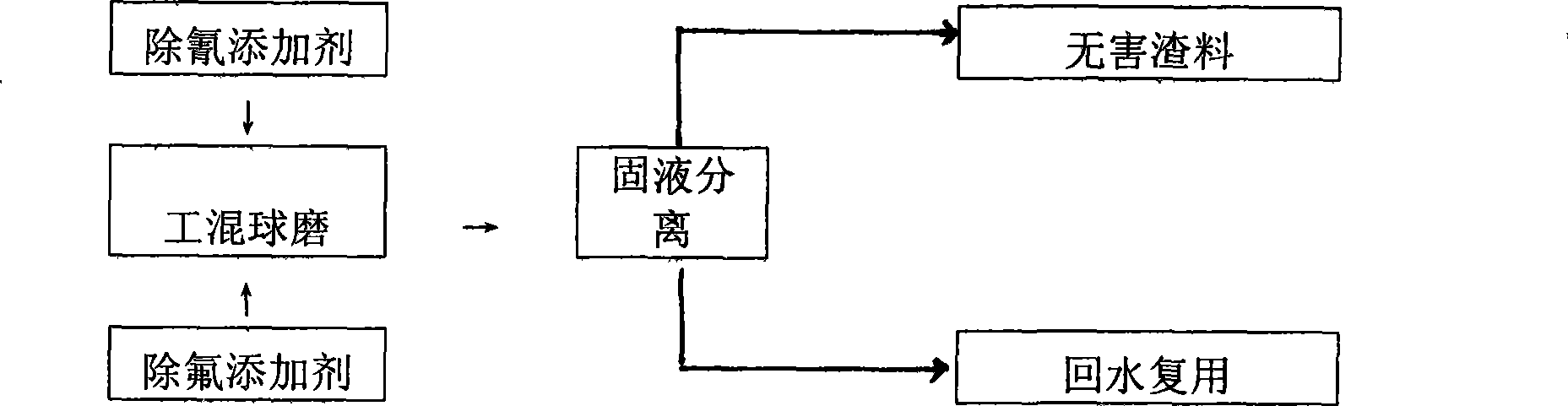

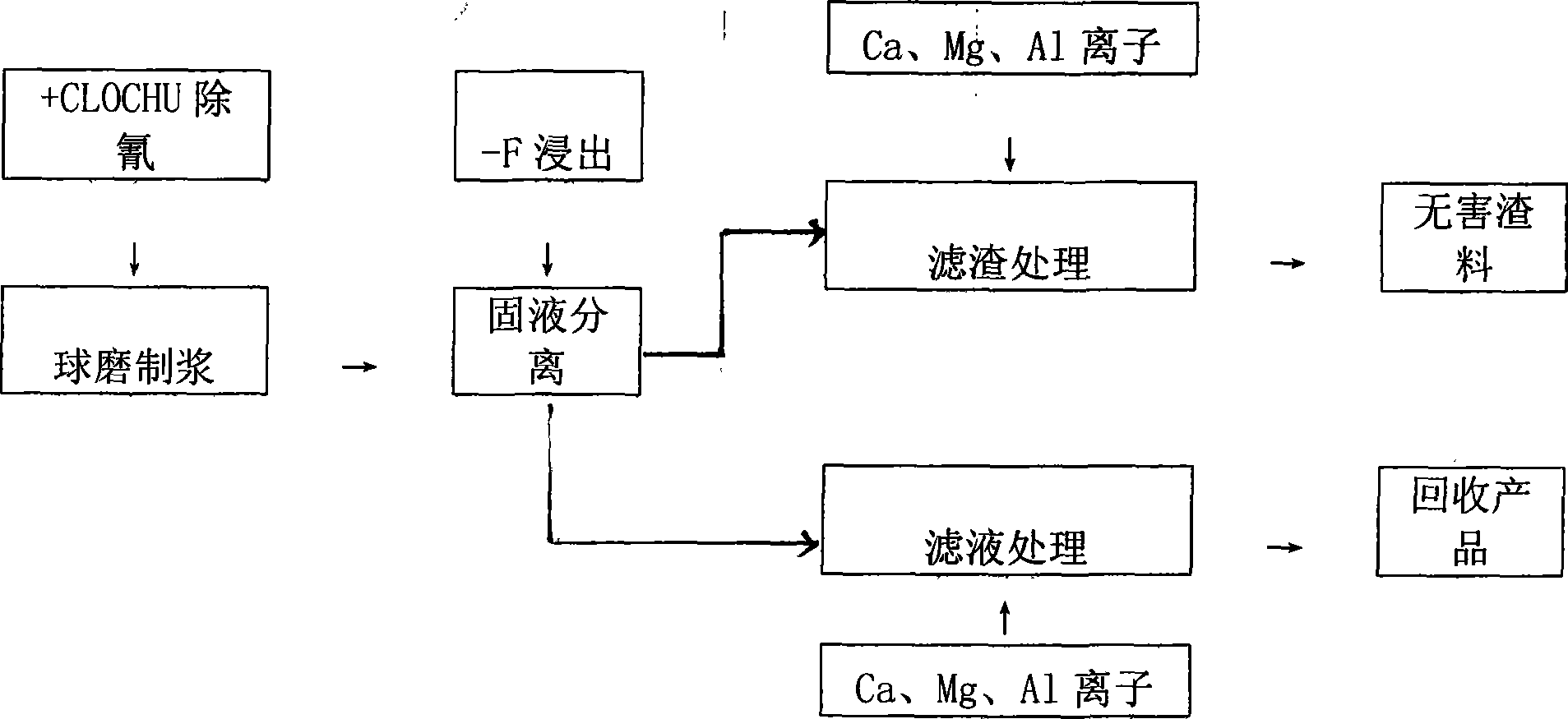

Method used

Image

Examples

Embodiment 1

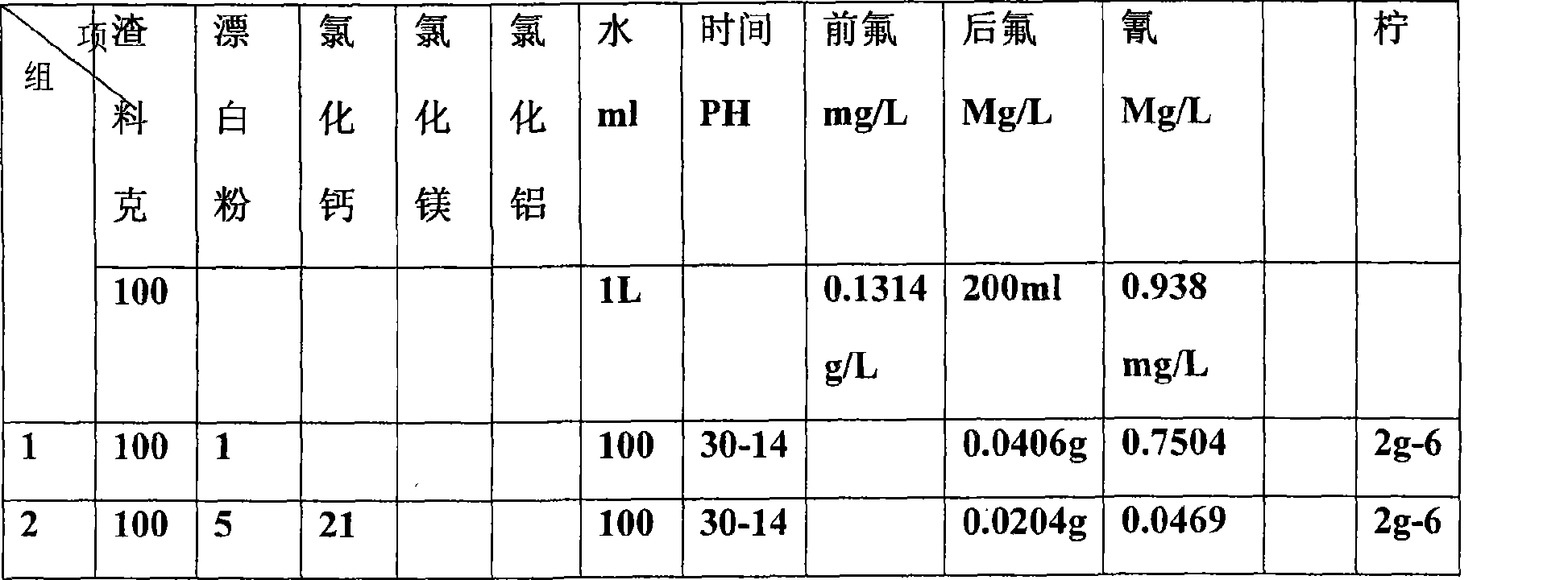

[0036] Put the overhaul slag and 15% by weight bleaching powder (25-32%) into the ball mill, add 100% water, ball mill to make pulp, control the ball mill time according to the loading, and add acid to the slurry after the test meets the standard. and discharge. Solid-liquid separation is sufficient.

Embodiment 2

[0038] Put overhaul slag and 5-10% bleaching powder (25-32%) and 100% water, ball mill for 1 hour, then add 50% calcium chloride hexahydrate by weight of overhaul slag, (or a mixture of hydrochloric acid and calcium carbonate) Ball milling until the pH value of the slurry is neutral, and the detection meets the discharge standard.

Embodiment 3

[0040] Ball mill the overhaul slag and 5-10% bleaching powder (25-32%) and 100% water for 1 hour, then add 50% magnesium chloride hexahydrate in the weight ratio of the overhaul slag, and ball mill until the pH value of the slurry is neutral. ,Discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com